Stripping and grinding machine for separating iron particles and silicate minerals from steel slag, and using method thereof

A technology of silicate minerals and iron particles, which is applied in the field of metallurgy, can solve the problems that steel slag tailings cannot be utilized as resources, steel slag cannot be processed in place, land occupation and environmental protection pressure are high, and the structure is simple, installation and layout are simple, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

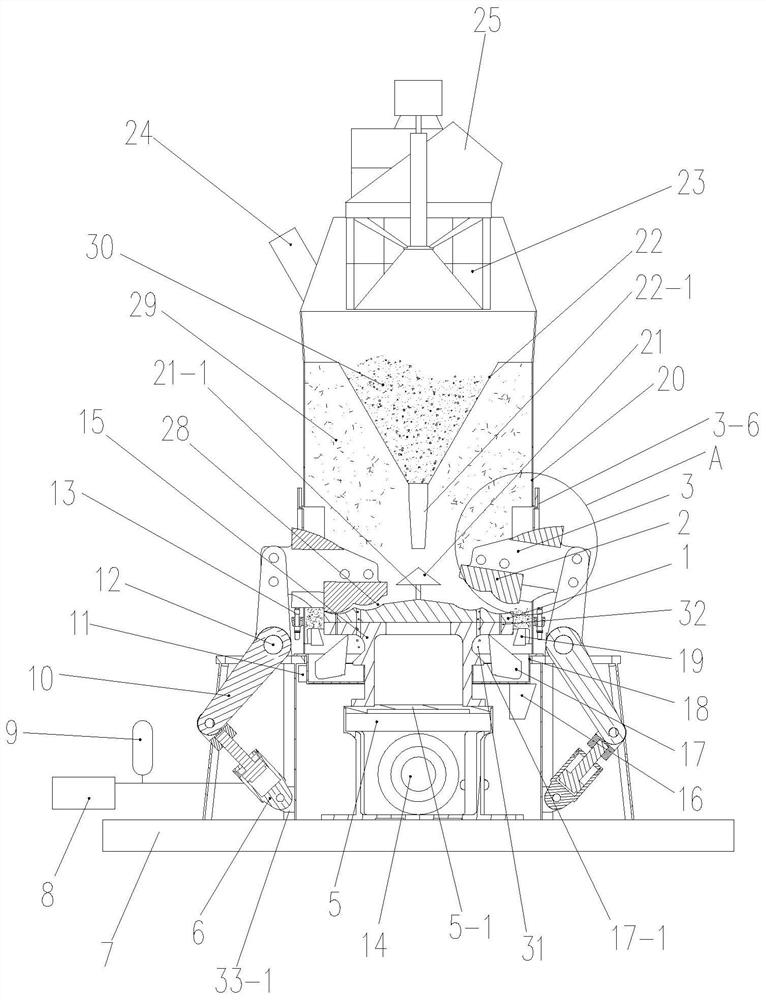

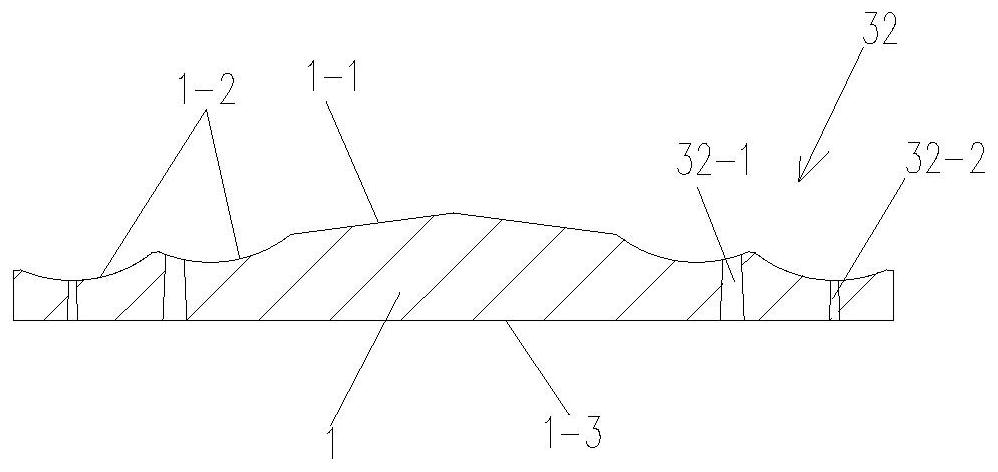

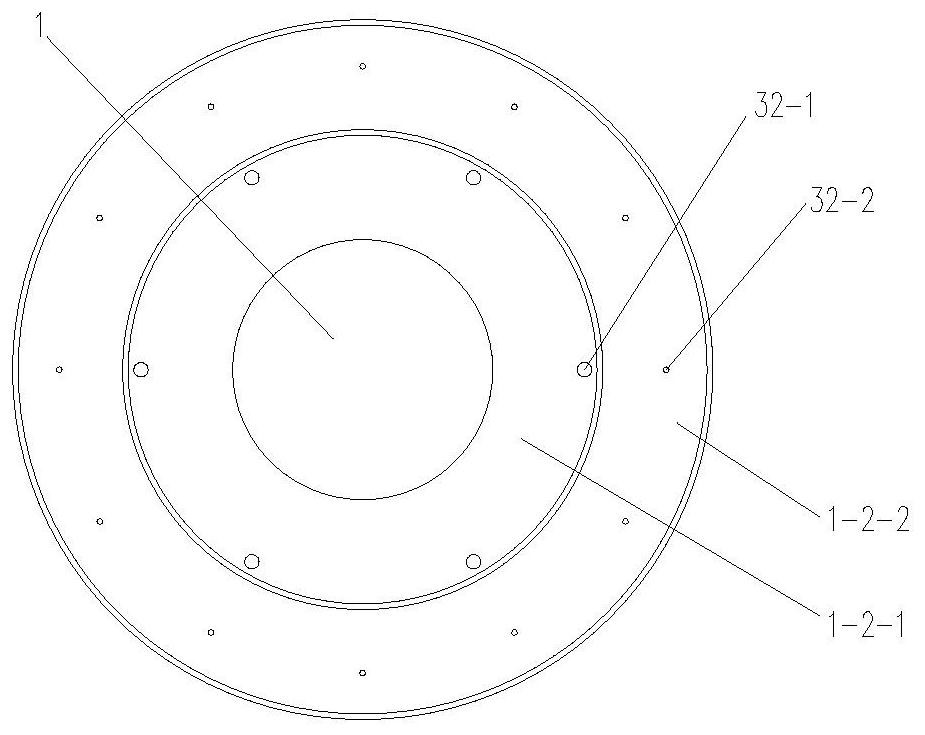

[0095] Such as Figure 1 to 17 The peeling machine separated from ferrite and silicate mineral in a steel slag, including a base 7, a housing 20, a horizontal rotation mounting, a lower rotating resistant body 1 and a lower rotating mill 1 The upper fixing grinding body 2, the lower rotating mill 1 and the upper fixing grinding body 2 form a peeled abrasive chamber 28, and the base 7 is provided with a pressure of steel slag 30 in the peeling chamber 28. Stripping pressure mechanism, the pressing mechanism drives the upper fixing grinding body 2 to be close or away from the lower rotary barrier 1;

[0096] The top of the housing 20 is provided with a feed tube 24 and a mount powder, and a lower body strip 22 is provided in the top of the housing 20, and the bottom and the housing of the mutter powder plate 23. 20 Inner communication, between the top of the lower hopper 22 and the bottom of the cage pickup machine 23 are provided with a gap, and a gap is provided between the top edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com