Upright surrounding type multidirectional die forging press

A multi-directional die forging and press technology, which is applied in the direction of forging presses, forging presses, forging press drive devices, etc., can solve the problem that the process performance and die forging precision cannot be improved, the multi-directional forging technology progresses slowly, and parts are not available. How to ensure the effect and precision, etc., to improve the precision and forging quality, reduce the vibration effect, and improve the modeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention will be described in detail below with reference to the drawings.

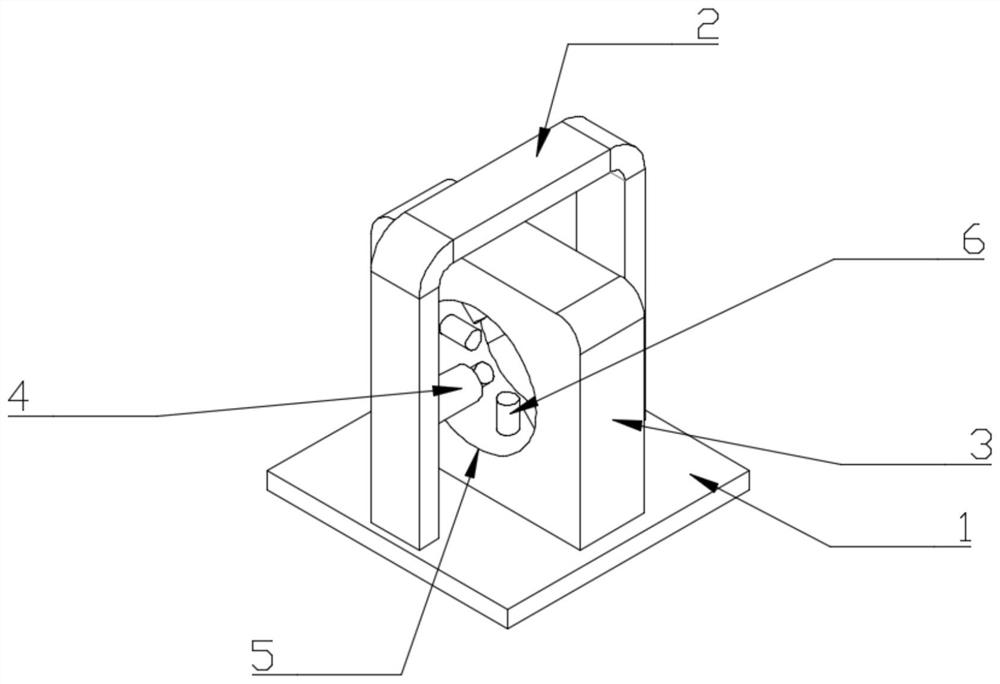

[0020]Such asfigure 1Down:

[0021]An upright enveloped multi-direction forging press, including a bottom plate 1, a horizontal forging arch # 2, and a ring forging device 3, the bottom plate 1 is a rectangular steel sheet, the bottom plate 1 sets an annular forging device 3, the ring forging The apparatus 3 is a vertical rectangular frame, and a circular vias is provided in the middle of the annular forging device 3. The inner wall of the circular vias is provided in the inner ring 5, and the ridge line of the working inner ring 5 is set to enhance the edge, and the inner ring 5 is surrounded Eight annular forging rods 6 are provided, the distance between the ring forging rods 6, the distance between the two, wherein the annular forging rod is vertically disposed, and the annular forging device 3 is welded to the bottom plate 1.

[0022]The bottom plate 1 is disposed on the plane, and the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com