Ultrasonic vibration auxiliary magnetic composite fluid polishing device

A technology of ultrasonic vibration and fluid polishing, applied in grinding/polishing equipment, optical surface grinders, metal processing equipment, etc., can solve the problems of reducing the processing quality of grating components and limiting the use efficiency of grating components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

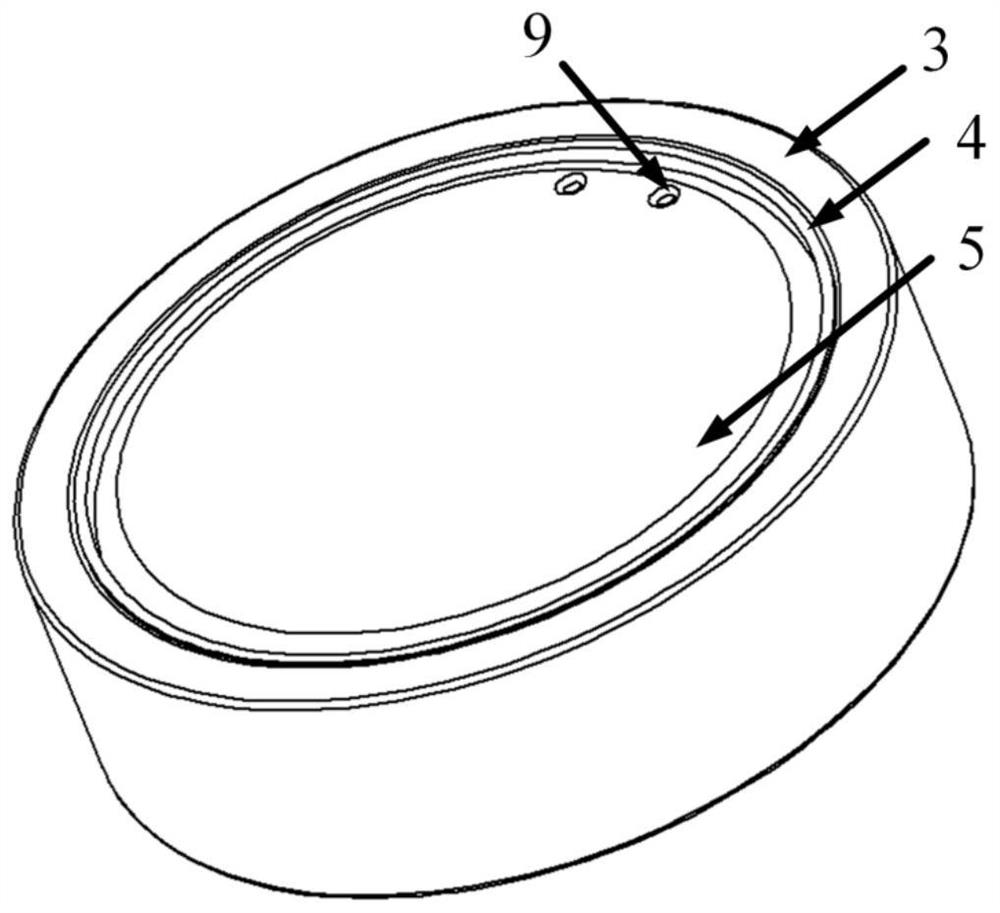

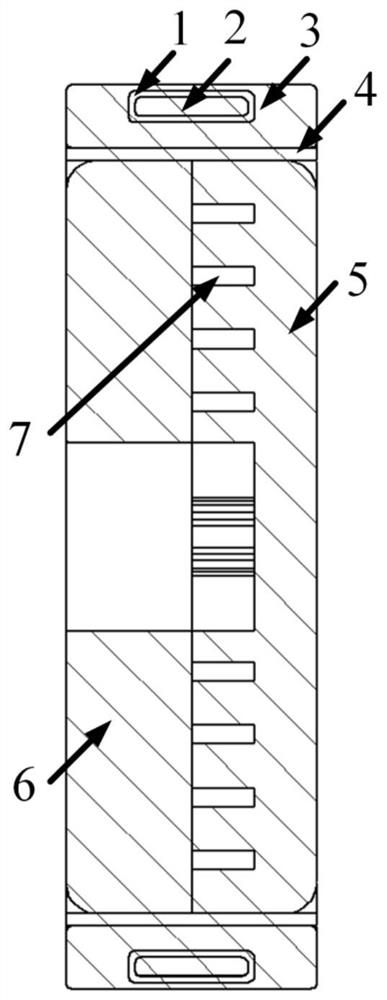

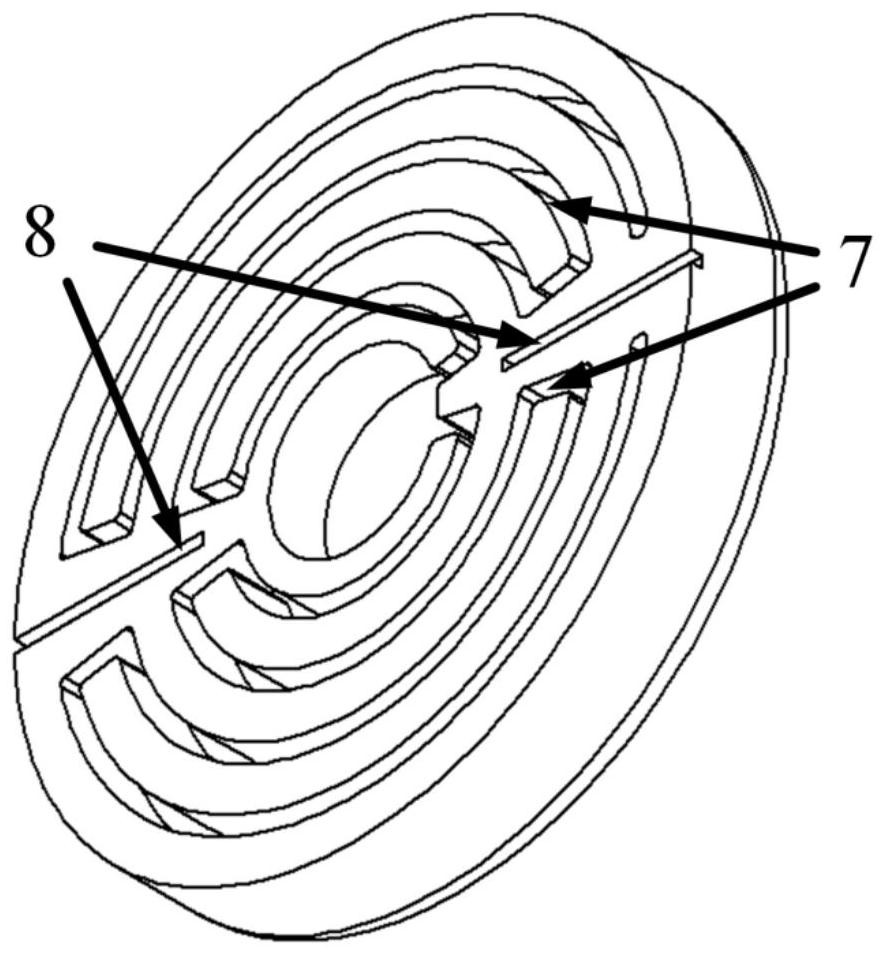

[0014] Such as Figure 1 to Figure 4 As shown, the ultrasonic vibration-assisted magnetic composite fluid polishing device of the present invention includes an insulating coating 1, a permanent magnet 2, a piezoelectric ceramic ring 3, a resin silica gel 4, a functional layer 5, a connecting layer 6, a cooling liquid channel 7, and a circuit line Channel 8, coolant outlet 9, electric spindle 10.

[0015] Such as figure 1 and image 3 As shown, the polishing head is composed of an insulating coating 1, a permanent magnet 2, a piezoelectric ceramic ring 3, resin silica gel 4 and a polishing wheel. The insulating coating 1 is evenly wrapped on the outer surface of the permanent magnet 2 by a physical vapor deposition process, and then sintered Inside the piezoelectric ceramic ring 3, the magnetic composite fluid is adsorbed on the outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com