Novel steel coil coreless cutting machine

A technology of cutting machine and steel coil, which is applied in the directions of coiling strips, thin material processing, transportation and packaging, etc., and can solve problems such as complicated operation, instability, and cumbersome unwinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

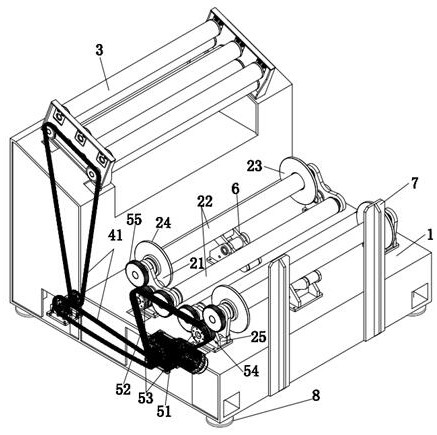

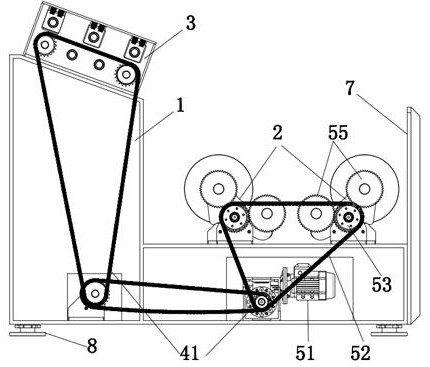

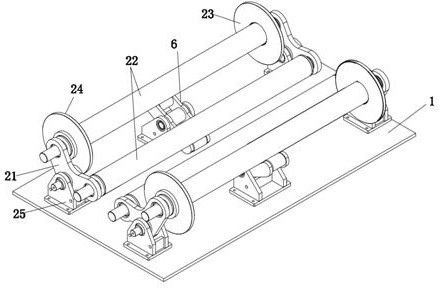

[0027] Such as Figure 1-4 As shown, a new type of steel coil coreless cutting machine includes a load frame 1 and at least two corresponding idler assemblies 2. In this embodiment, the number of idler assemblies 2 is two, and they are arranged symmetrically. The idler roller assembly 2 includes a rotating support frame 21 located on both sides and a number of rotating idler rollers 22 rotatably connected to the rotating support frame 21. The rotating idler rollers 22 on both sides form a "V"-shaped supporting space, and 9 steel coils are placed In the "V"-shaped supporting space, it is supported by several rotating idlers 22, and generates friction with several rotating idlers 22 under its own gravity, so as to realize the rotation, and because it is placed in the "V"-shaped supporting space Inside, its rotation process is very stable;

[0028] The rotating support frame 21 is connected to the idler base 25 by rotating pins, so that it can swing within a certain range, there...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 , figure 2 , Figure 6 , Figure 7 As shown, one end (i.e., the discharge end) of the carrying frame 1 is also provided with a traction mechanism 3, and the traction mechanism 3 includes several upper rollers 31 arranged in parallel, several lower rollers 32 and two side roller bracket 33, the two ends of the upper roller shaft 31 and the lower roller shaft 32 are rotatably connected to the roller shaft bracket 33, wherein several lower roller shafts 32 are synchronously driven to rotate through the first transmission system 41, and the second A transmission system 41 is a first chain transmission system, and the drive element 51 drives several lower roller shafts 32 to rotate synchronously through the first chain transmission system at the same time, and the material sheet passes between the upper roller shaft 31 and the lower roller shaft 32, The forward traction movement of the tablet is realized by friction.

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com