Filter-pressing type water electrolyser

A technology of water electrolysis cell and filter press, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problem of high insulation requirements of tie rod components, achieve good insulation and waterproof performance, and avoid the effect of excessive length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation will be described below in conjunction with the accompanying drawings.

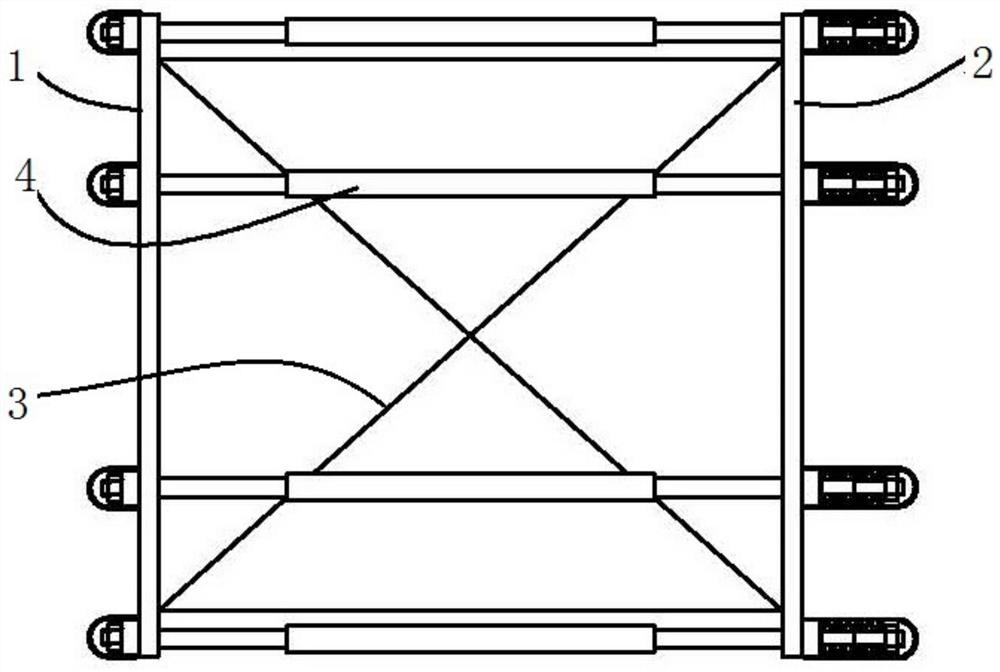

[0022] In this embodiment, the pressure filter type water electrolyzer is as figure 1 As shown, it includes a front end plate 1 and a rear end plate 2 located at both ends of the electrolytic cell, several electrolytic chamber components 3 arranged between the front end plate 1 and the rear end plate 2 and stacked in sequence, several groups of the front end plate 1 and the rear end plate The end plate 2 is locked and connected with an insulating pull rod assembly 4 . The electrolysis cell assembly 3 is composed of a frame, electrode plates, diaphragms and other components arranged in the frame. The positive and negative terminal plates of the electrolytic cell are arranged at both ends of the electrolytic cell, and direct current is connected to realize the electrolysis of water to generate hydrogen and oxygen.

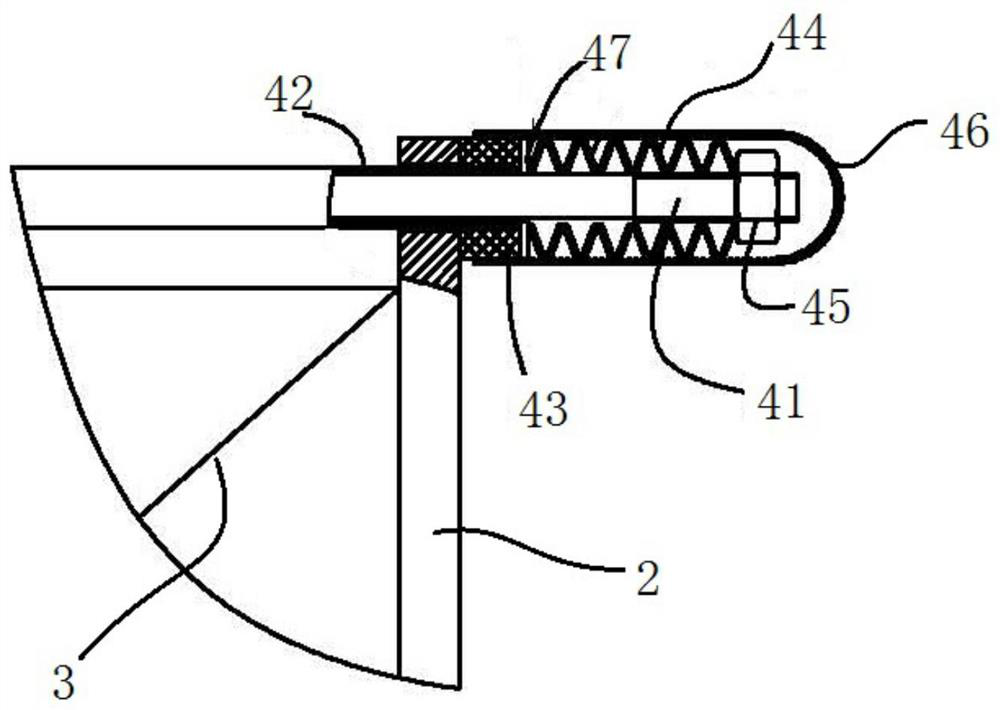

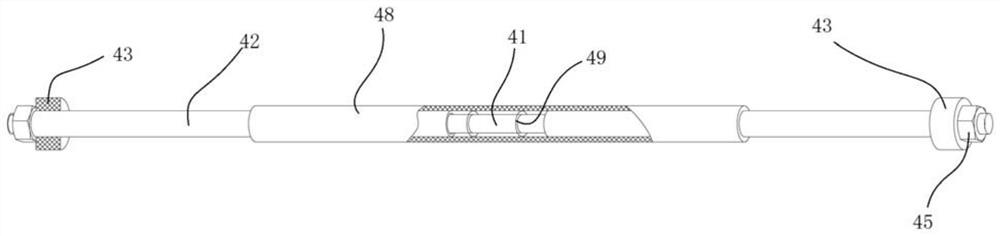

[0023] Such as figure 2 image 3 As shown, the insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com