Light guide plate detector and using method thereof

A light guide plate and detector technology, which is applied in the direction of testing optical performance, etc., can solve the problems of low product quality, poor processing quality of light guide plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The embodiment of the present application discloses a light guide plate detector.

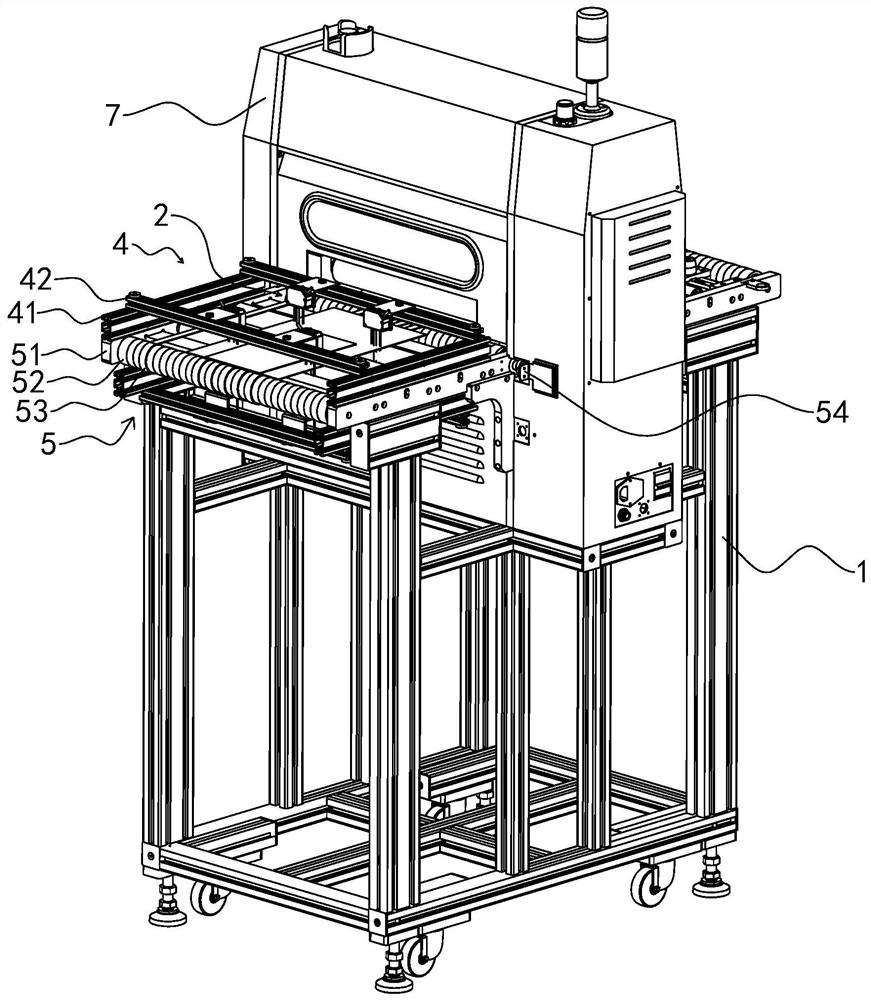

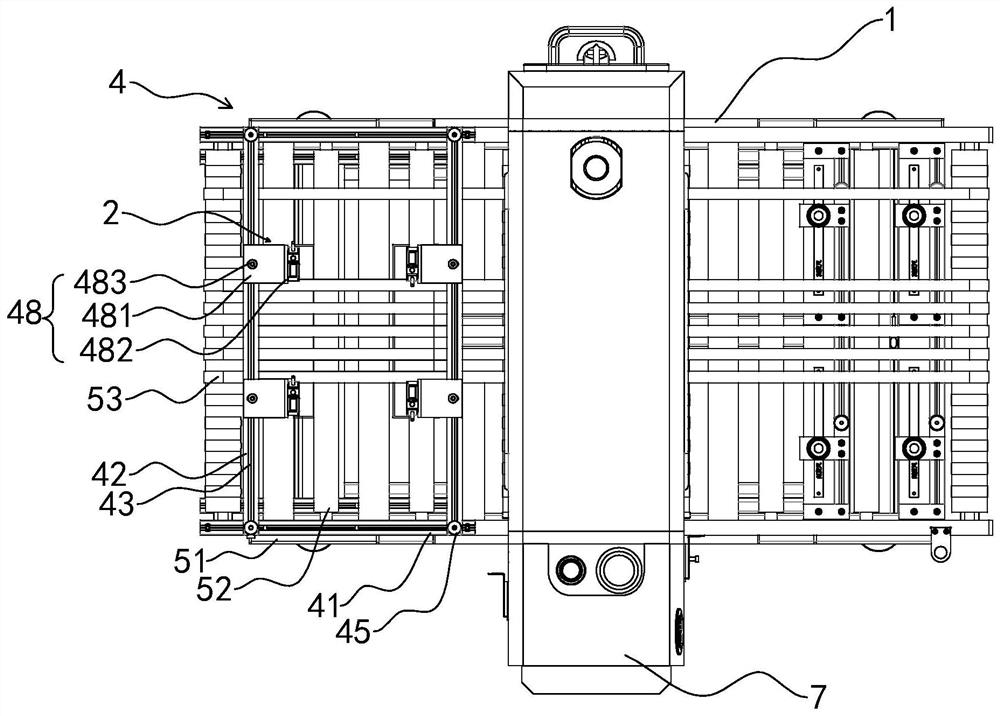

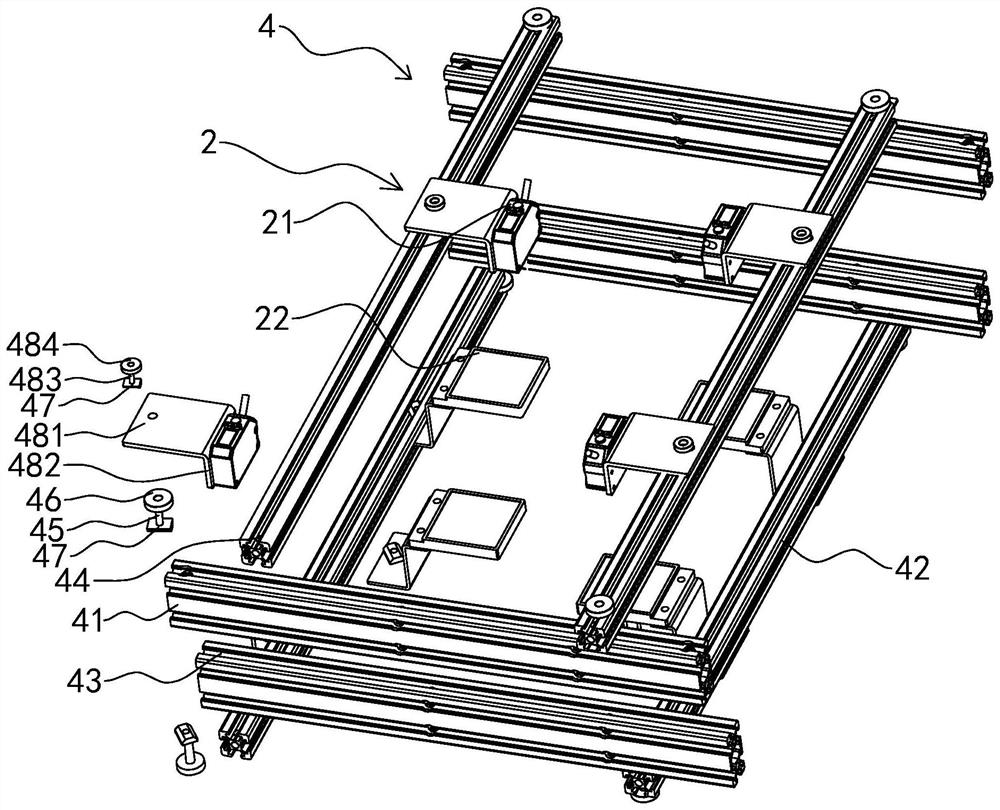

[0047] refer to figure 1 , a light guide plate detector, comprising a body 1, a cleaning device 7 for cleaning the surface of the light guide plate is installed in the middle of the body 1, and the output end of the cleaning device 7 is provided for driving the light guide plate to facilitate the automation of the light guide plate A conveying device 5 for ground feeding, detection and discharging. The conveying device 5 includes two fixed plates 51 arranged symmetrically in parallel along the discharge direction of the light guide plate. Several conveying rollers 52 are erected between the two fixed plates 51, and several The transmission rollers 52 are arranged at a certain interval, and the transmission rollers 52 are provided with several conveyor belts 53 for contacting with the light guide plate and driving the light guide plate to move. A certain interval is set at intervals, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com