Optimization method for pretightening force of brittle sandwich structure bolt

A technology of bolt pre-tightening force and sandwich structure, which is applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems affecting the air tightness of sandwich structures, brittle sandwich rupture, high hardness and brittleness, etc., to improve accuracy and Effects of mechanical properties, reduction of local deformation, optimization of stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

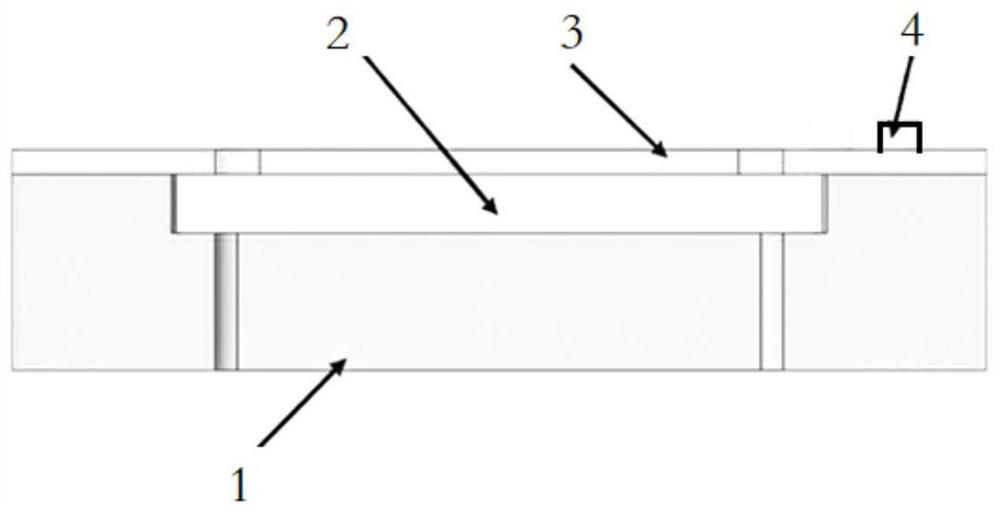

[0032] The invention provides a method for optimizing the bolt pretightening force of a brittle sandwich structure, which is aimed at figure 2 The optimization method of how a circle of bolts in the brittle sandwich structure shown in the figure realizes the pre-tightening force. In the figure, the upper surface of the substrate 1 has a groove, and the glass 2 is installed in the groove, and the cover plate 3 is placed on the substrate 1 and the glass 2 at the same time. On the surface of the cover plate 3 and the base plate 1 are fixed by bolts 4, and the bolts 4 are distributed along a rectangular frame on the cover plate.

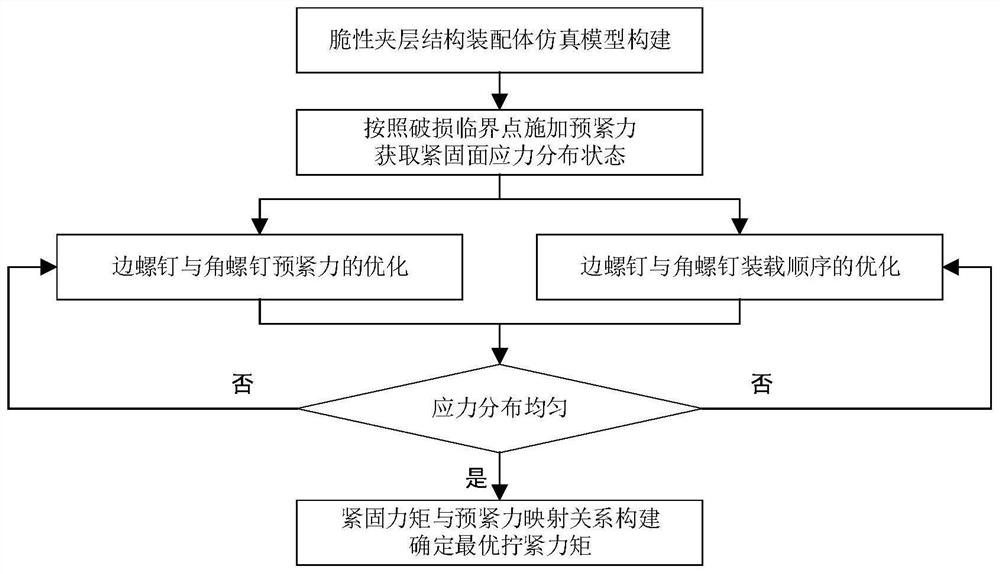

[0033] as attached figure 1 As shown, the steps of this method are as follows:

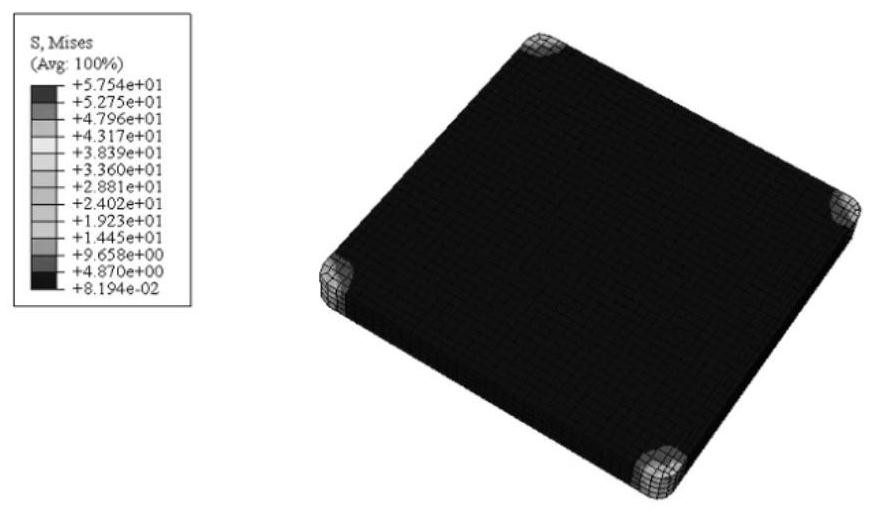

[0034] Step 1: Construct a three-dimensional assembly model of the brittle sandwich structure in the finite element software of the computer and defi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com