Wire harness fixing and protecting device for machine vision detection

A machine vision inspection and wire harness fixing technology, applied in electrical components and other directions, can solve the problems of wire harness falling off, pulling, easy to bend, etc., to prevent bending, reduce friction, and quickly adjust the guiding orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

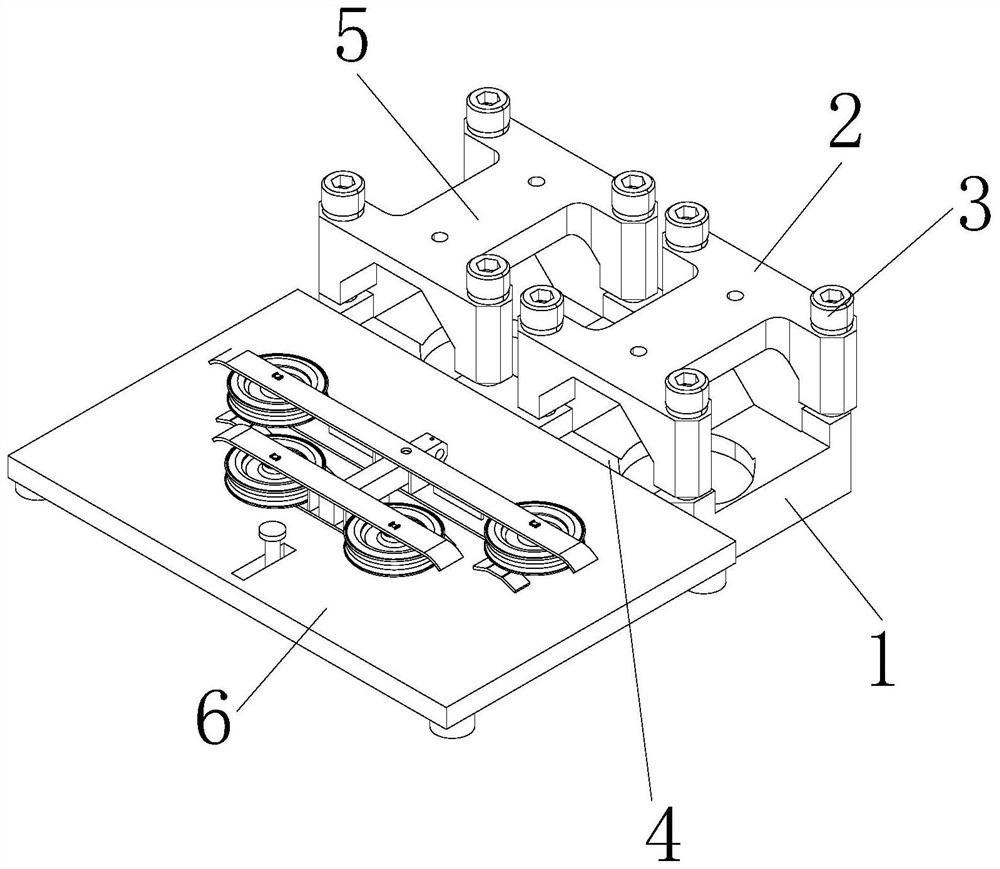

[0028] see figure 1 , the present invention provides a wire harness fixing protection device for machine vision detection through improvement, including a base 1, a first cover plate 2, bolts 3, slots 4, a second cover plate 5 and a wire management mechanism 6, the base 1 The bolt 3 is locked and fixed with the bottom of the first cover 2, and the cable management mechanism 6 is installed and fixed on the front end of the base 1. The upper ends of the base 1 and the first cover 2 are provided with slots 4, and the left end of the top of the base 1 is provided with a second cover. plate 5.

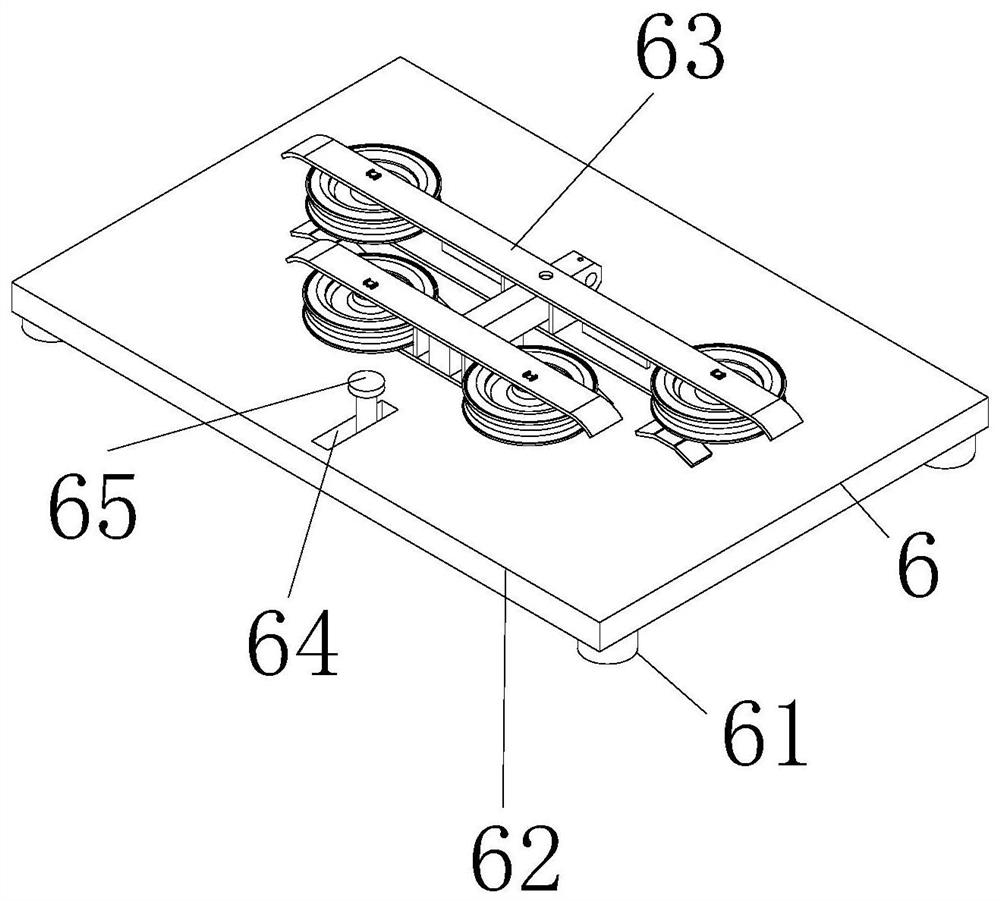

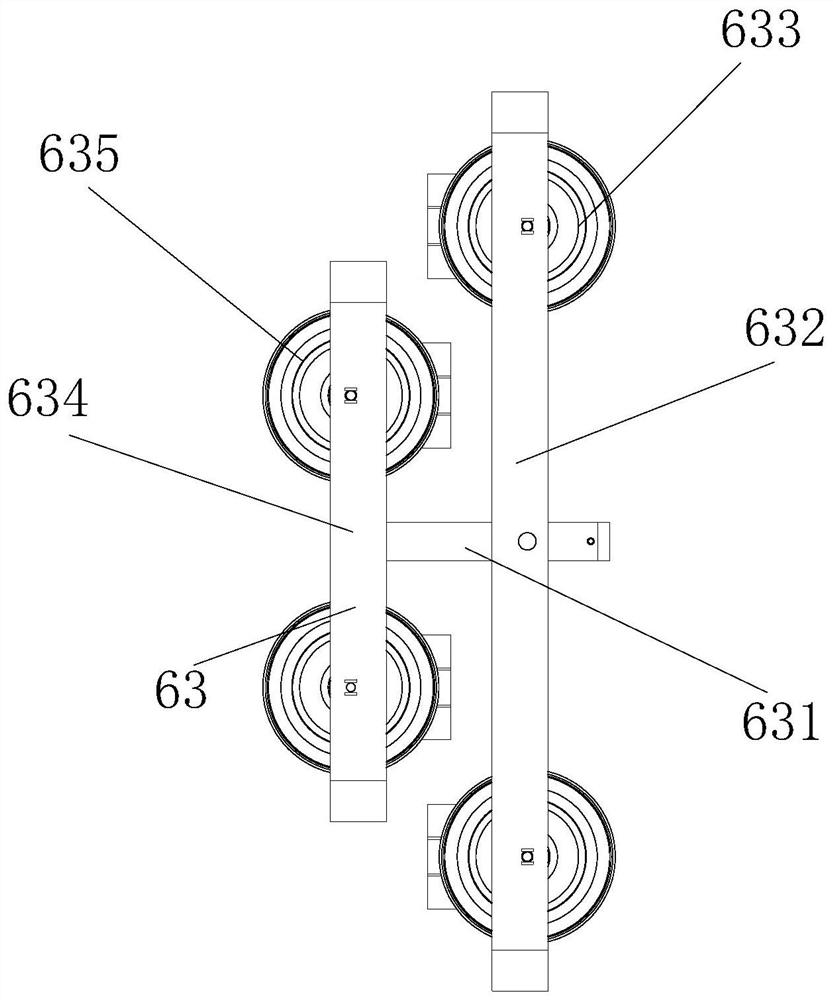

[0029] see figure 2 , the present invention provides a wire harness fixing and protection device for machine vision inspection through improvement. 62 is fixedly connected with the front end of the base 1, the fixed frame 62 is fixed with the bottom four corners of the anti-skid block 61, the top of the fixed frame 62 is provided with a guide wheel mechanism 63, the front end of the top ...

Embodiment 2

[0033] The present invention provides a fixed protection device for machine vision detection wire harness through improvement. The fixed frame 62 is in the shape of a cuboid with an inner cavity, which is beneficial to install and fix the rotation limiting mechanism 65. The first cover plate 2 and the second cover plate The two cover plates 5 have the same size, and the first cover plate 2 and the second cover plate 5 are distributed parallel to each other, which is beneficial to fix the wiring harness.

[0034] The present invention provides a fixed protection device for machine vision detection wire harness through improvement, and its working principle is as follows;

[0035] First, before use, place the wire harness fixing protection device for machine vision detection horizontally, so that the base 1 and the anti-slip block 61 can fix and support the device;

[0036] Second, when in use, pass a plurality of wire harnesses through the inside of the first cross bar 632 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com