Double-material mixing cosmetic dropper bottle

A cosmetic and dual-material technology, applied in the directions of packaging cosmetics, packaging item types, cosmetic powder containers, etc., can solve the problems of complex operation of the dual-material dropper bottle and the small amount of materials contained, and achieves simple assembly and operation. , the effect of high user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

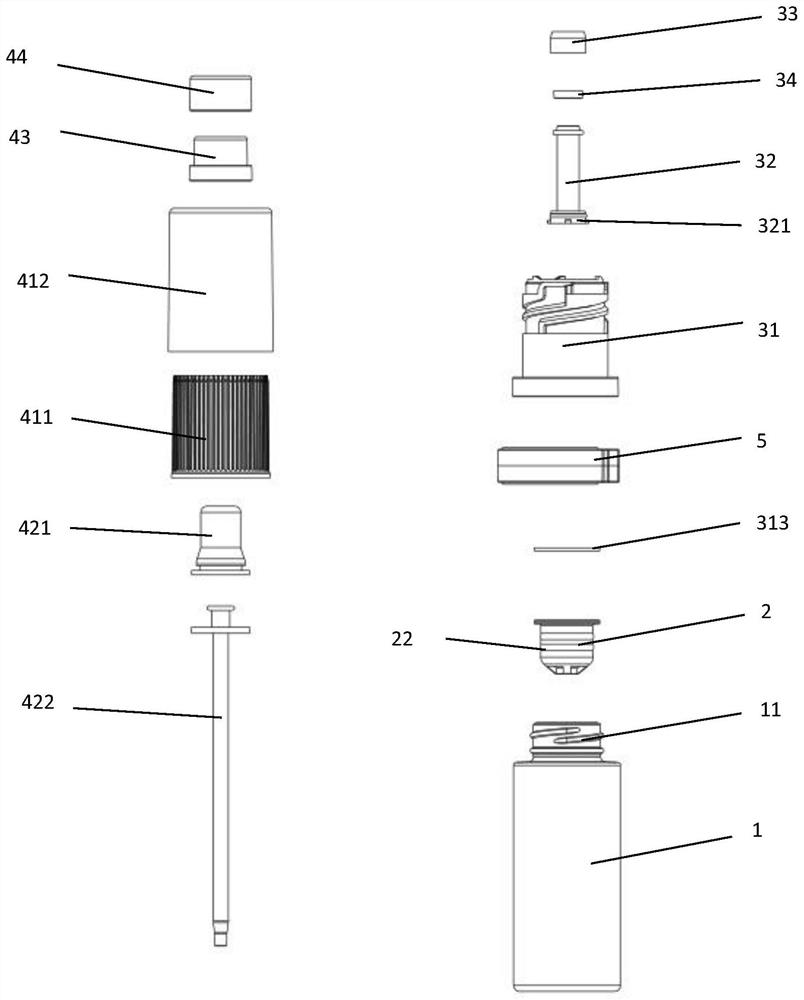

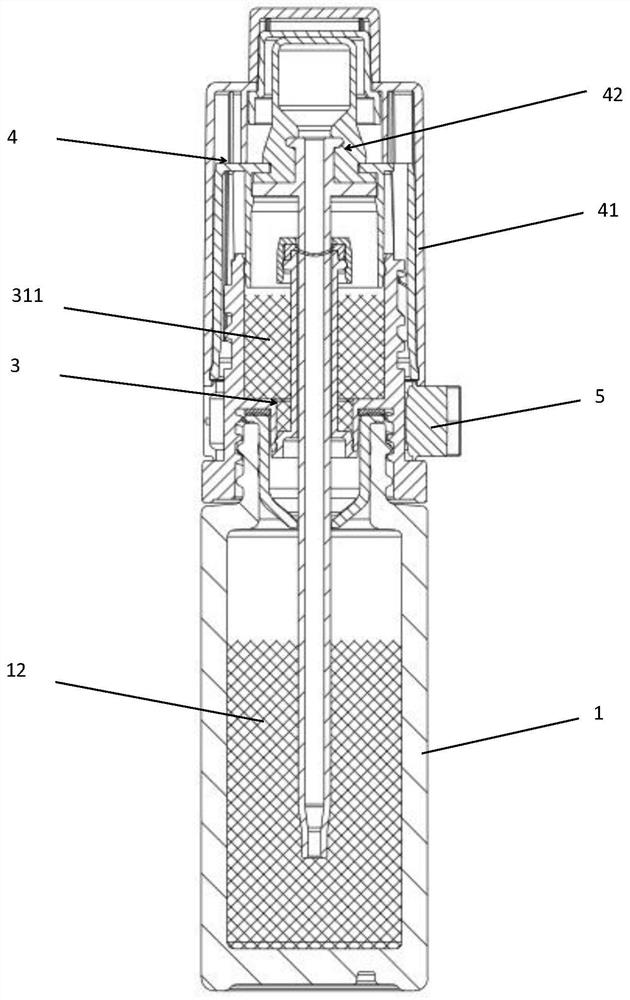

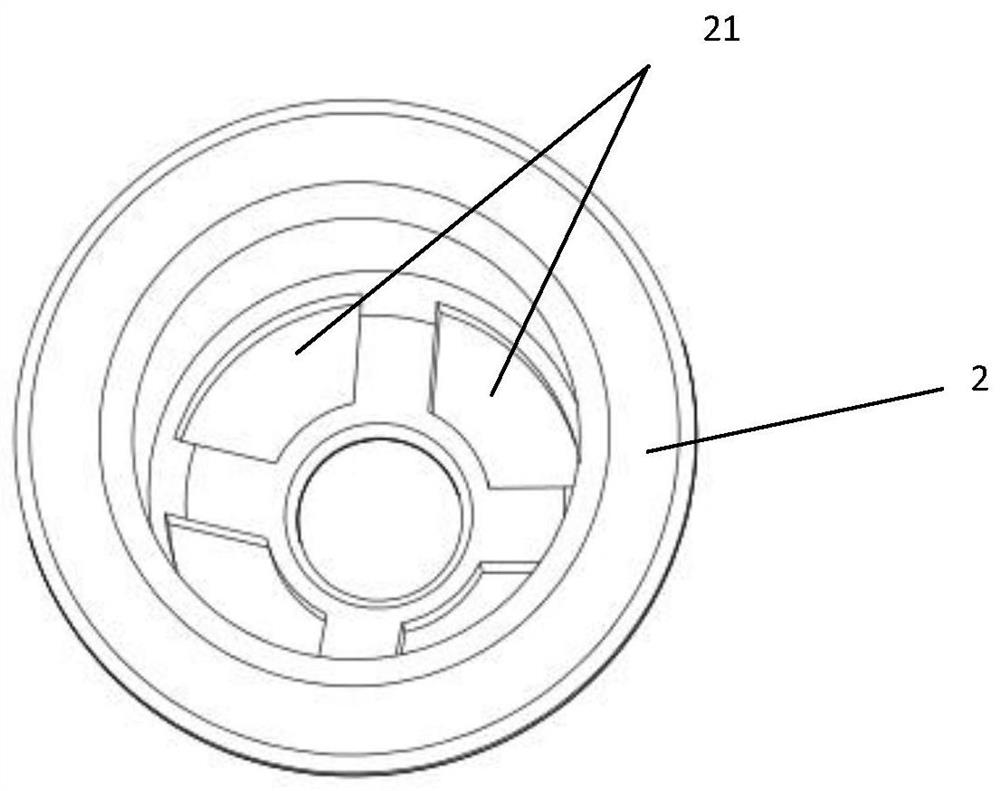

[0041] For a double-material mixed cosmetic dropper bottle provided by an embodiment of the present invention, please refer to figure 1 , figure 2 , image 3 and Figure 4Shown, comprise bottle body 1, the upper end of bottle body 1 is provided with bottleneck 11, is provided with inner plug 2 in the bottleneck 11 of bottle body 1, the inside of inner plug 2 is a cavity, and is provided with along the inner bottom of inner plug 2. A plurality of material body openings 21, a sealing ring 22 is set on the outer wall of the inner plug 2, and the inner plug 2 and the bottleneck 11 of the bottle body 1 are sealed by the sealing ring 22, and the material body 1 is stored in the bottle body 1. The bottle mouth 11 is provided with a collection assembly 3 for containing the second material body 311. Before use, the first material body 12 and the second material body 311 are stored in a separate manner, and the collection assembly 3 is provided with a material collection assembly 4. ...

Embodiment 2

[0052] It shows a method of operating a double-material mixed cosmetic dropper bottle in a preferred embodiment, including the above-mentioned double-material mixed cosmetic dropper bottle, please refer to Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown in Figure 14, the operation method includes the following steps:

[0053] Step 1: Open the C-shaped buckle 5, and rotate the screw cap 41 clockwise on the dental cap 31 to the end, the screw cap 41 drives the rubber dropper 42 to move downward, the sealing plug 321 is separated from the discharge port 312, and the discharge port 312 guides Through, the material body two 311 in the tooth cap 31 flows into the bottle body 1, and the material body two 311 and the material body one 12 are mixed with each other;

[0054] Step 2: Open the gland cover 44, press the gland 43 to the bottom, the glue head 421 of the glue head dropper 42 is compressed and deformed, the negative pressure is formed in the glue head dropper 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com