Sputum suction device for delivery room

A delivery room and straw technology, applied in the direction of suction devices, drug devices, coatings, etc., can solve problems such as difficulty in clearly viewing the oral sputum of newborn babies, discomfort caused by damage to oral tissues of newborn babies, and difficulty in visualizing sputum suction. Achieve the effect of convenient and precise suction, reduce risk and discomfort, and good antisepsis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

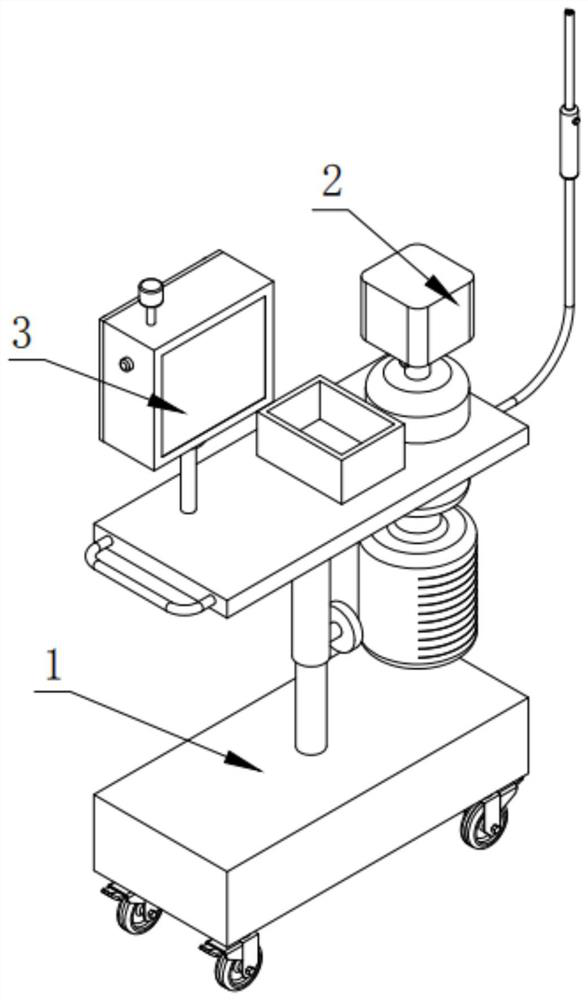

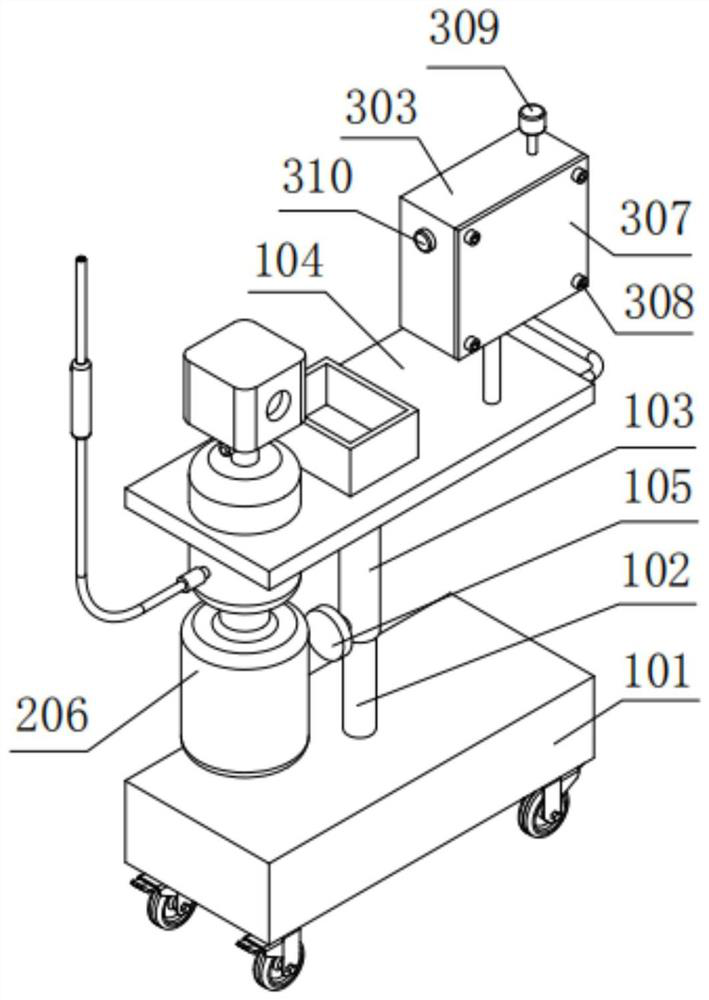

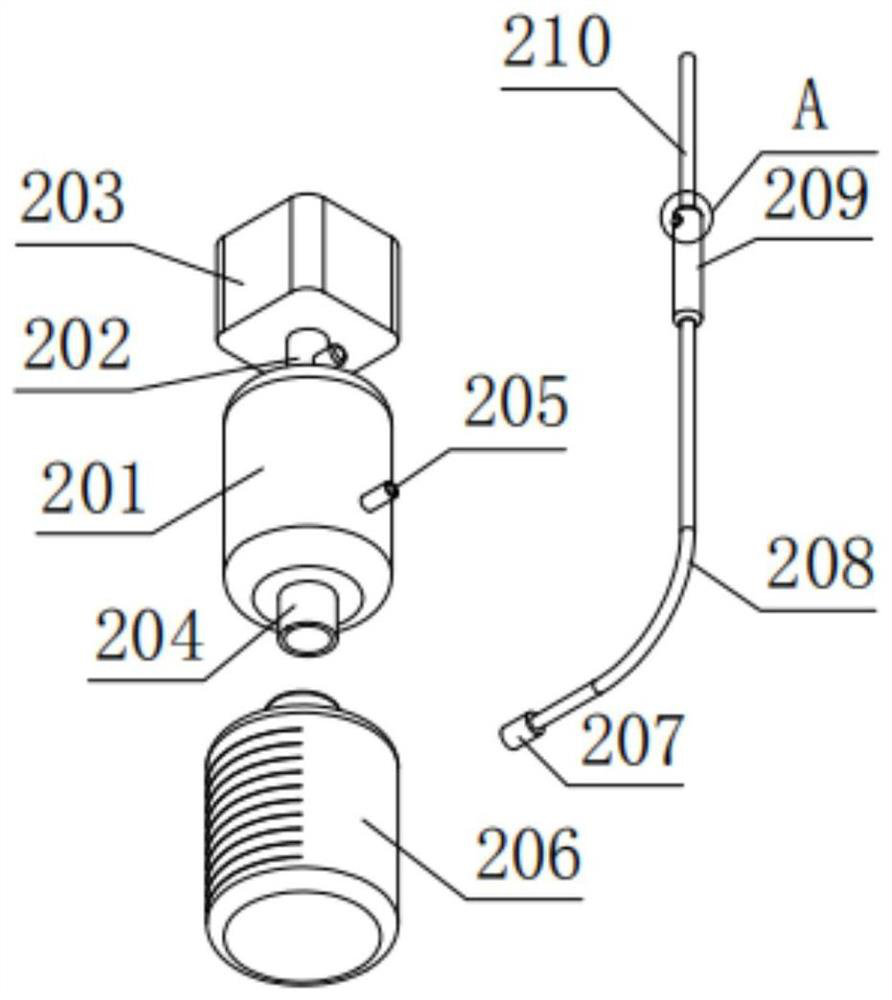

[0047] A sputum suction device for delivery room, such as figure 1 As shown, it includes: a main structure 1, the upper part of the main structure 1 is provided with a sputum suction mechanism 2 and a control mechanism 3;

[0048] Wherein, the sputum suction mechanism 2 is used to generate negative pressure and use the negative pressure to complete the purpose of sputum suction;

[0049] Wherein, the control mechanism 3 is electrically connected with the sputum suction mechanism 2, and the control mechanism 3 is used to control the sputum suction mechanism 2 to generate a stable negative pressure environment to ensure the stable operation of the sputum suction device for delivery room.

[0050] The sputum suction device designed above is mainly composed of a main structure 1, a sputum suction mechanism 2 and a control mechanism 3. The medical staff can use this device to conveniently suck out the sputum in the mouth of the newborn baby, which can effectively prevent the newbor...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that a protective layer is also provided on the inner wall of the cylindrical housing 201, and the protective layer is prepared by the following method:

[0063] Take the following raw materials and weigh them by weight: 12 parts of epoxy resin, 6 parts of calcium carbonate powder, 4 parts of nano-silver powder, 12 parts of polytetrafluoroethylene, 2 parts of alcohol ester twelve, 2 parts of triethanolamine, 1 part of emulsified silicone oil and 20 parts of water;

[0064] S1. Add epoxy resin, calcium carbonate powder, nano-silver powder, and polytetrafluoroethylene into a pulverizer and pulverize until the particle diameter of the above-mentioned materials is not greater than 100nm to obtain a mixed powder material;

[0065] S2. Add the mixed powder material prepared in step S1, alcohol ester dodeca, triethanolamine, emulsified silicone oil and water into a beaker and stir, stir for 10 minutes, put it on an alc...

Embodiment 3

[0074] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0075] Take the following raw materials and weigh them by weight: a protective layer is also provided on the inner wall of the cylindrical shell 201, and the protective layer is prepared by the following method:

[0076] Take the following raw materials and weigh them by weight: 18 parts of epoxy resin, 10 parts of calcium carbonate powder, 6 parts of nano-silver powder, 16 parts of polytetrafluoroethylene, 4 parts of alcohol ester twelve, 4 parts of triethanolamine, 3 parts of emulsified silicone oil and 40 parts of water;

[0077] S1. Add epoxy resin, calcium carbonate powder, nano-silver powder, and polytetrafluoroethylene into a pulverizer and pulverize until the particle diameter of the above-mentioned materials is not greater than 100nm to obtain a mixed powder material;

[0078] S2. Add the mixed powder material prepared in step S1, alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com