Vertical hyperbolic stirring impeller and stirrer thereof

A mixing impeller and hyperbolic technology, which is applied in the field of vertical hyperbolic mixing impeller and its mixer, and sewage treatment equipment, can solve the problems of high power of the matching motor and reducer, increased unit operating cost, increased energy consumption, etc., to achieve The effect of energy consumption reduction, cost saving and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

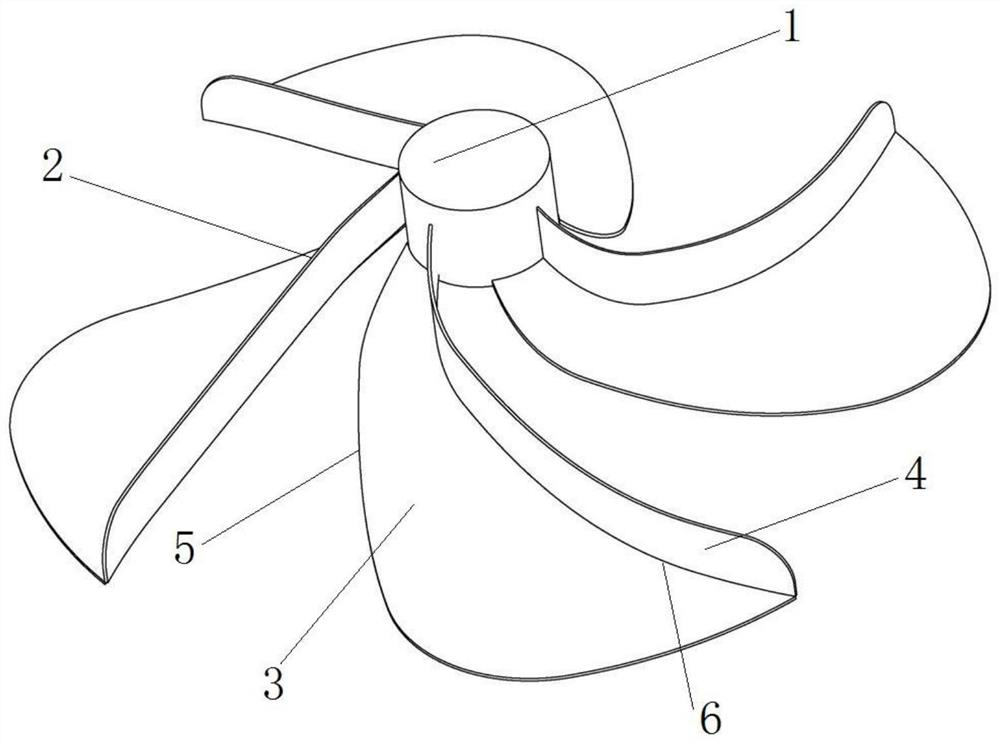

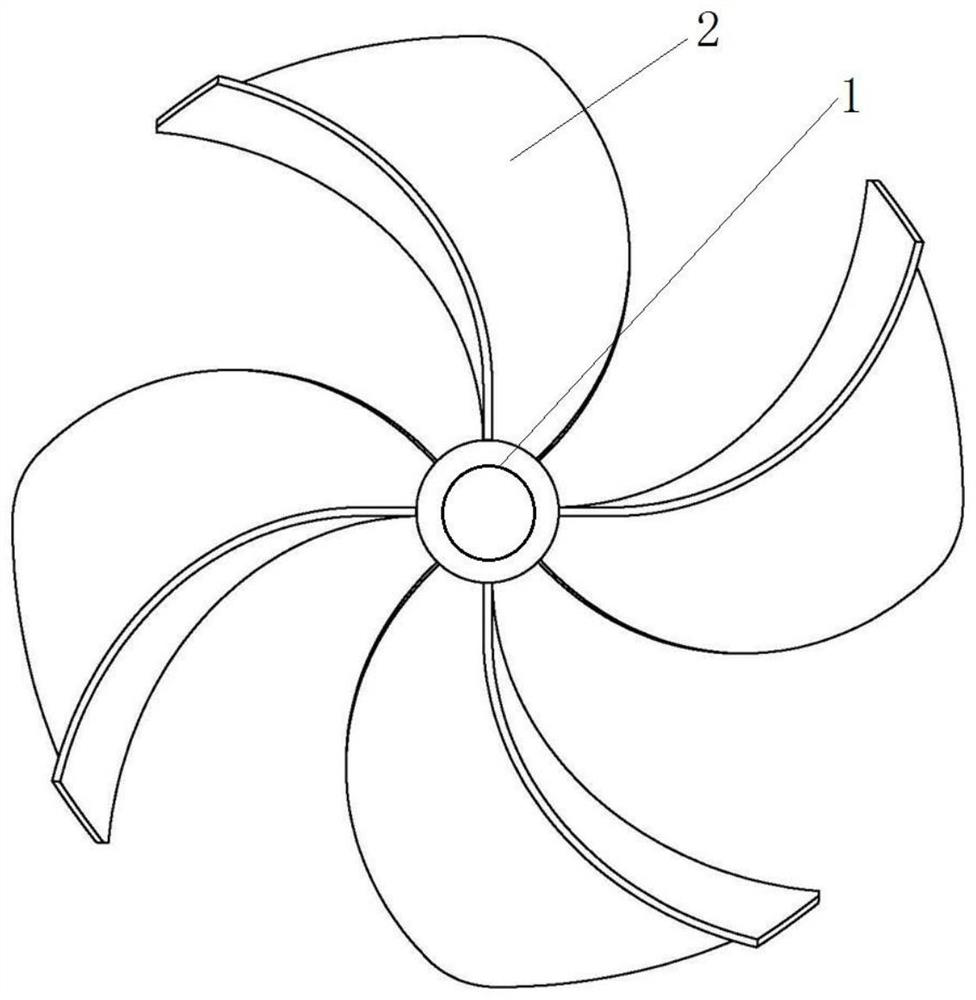

[0024] Such as figure 1 with 2 As shown, a vertical hyperbolic stirring impeller, which includes a mounting base 1 and blades 2, at least two blades 2 are provided, and the blades 2 are evenly connected around the mounting base 1, and the blades 2 include a flow guide Plate 3 and flow plate 4, the surface of the flow plate 4 is curved, and the curved surface of the plate surface is twisted, which is gradually twisted from the axial end to the outer end, and the flow plate 4 protrudes upwards for installation At the rear edge 6 of the deflector plate 3, the front edge 5 and the rear edge 6 of the deflector plate 3 are curved, and the bending direction of the front edge 5 and the rear edge 6 is in line with the bending direction of the pusher plate 4. Consistent, and at the same time, the surface area of the deflector plate 3 gradually increases from the inner connection end to the outer extension end.

[0025] In this embodiment, the blades 2 are installed horizontally or i...

Embodiment 2

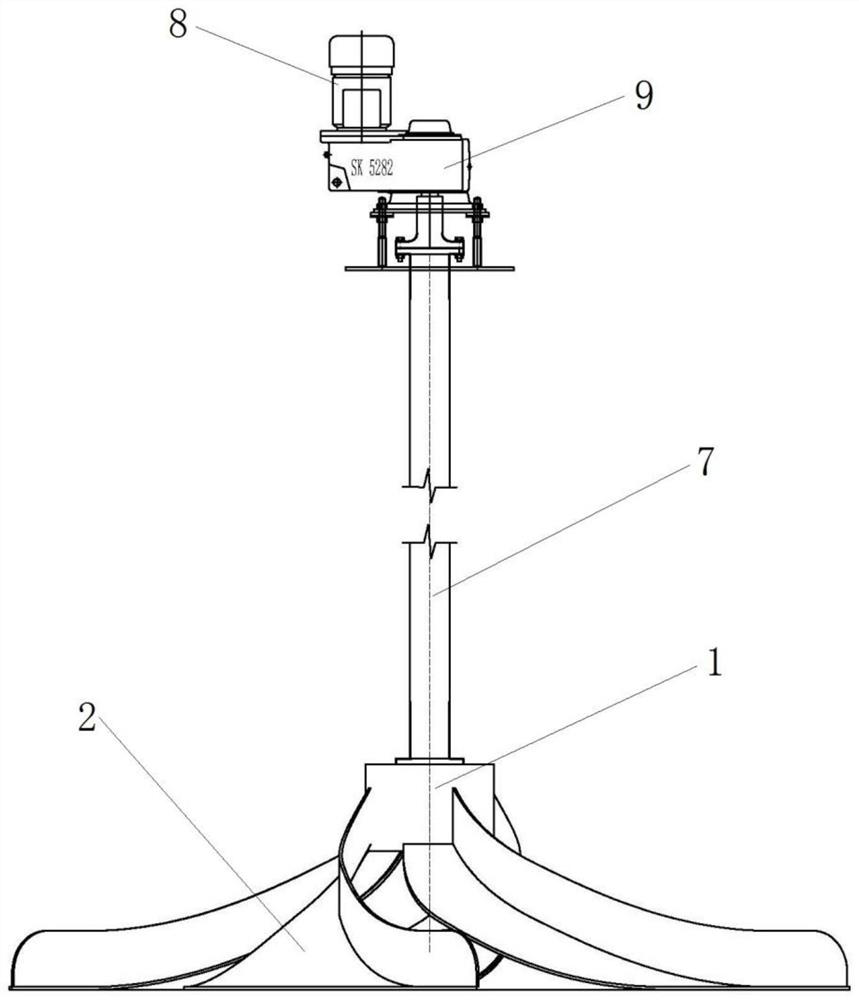

[0031] Such as image 3 As shown, a vertical hyperbolic agitator includes the vertical hyperbolic agitating impeller described in Embodiment 1 and a drive mechanism for driving the impeller to rotate. connected. The drive mechanism includes a motor 8 and a reducer 9, the output end of the motor 8 is connected to the input end of the reducer 9, the output end of the reducer 9 is connected to the top of the rotating shaft 7, and the bottom end of the rotating shaft 7 is fixedly connected to the vertical hyperbolic stirring Mounting seat for impeller 1.

[0032] The working principle of the present invention: during the rotation of the blade, the deflector plate drags the liquid on it, and the pusher plate rotates to push the liquid in front of it to the surroundings. Due to the unique curved surface structure of the flow guide plate and the pusher plate , during the rotation of the blade, the pusher plate of the blade pushes the liquid in its area away to spread 360 degrees ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com