Physical polishing device for laboratory

A laboratory and physical technology, applied in grinding drives, grinding machines, grinding racks, etc., can solve problems such as waste of resources, scrapped grinding wheels, and inability to move grinding wheels, saving costs, prolonging service life, avoiding The effect of the fixed position of the grinding wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

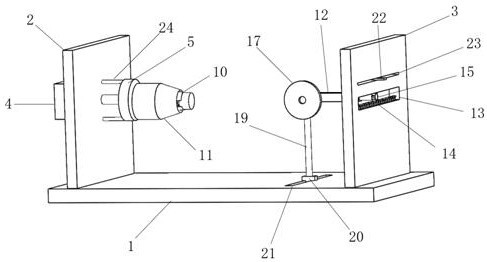

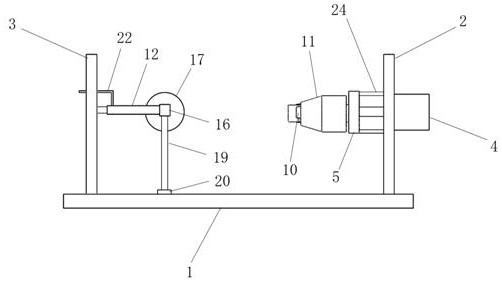

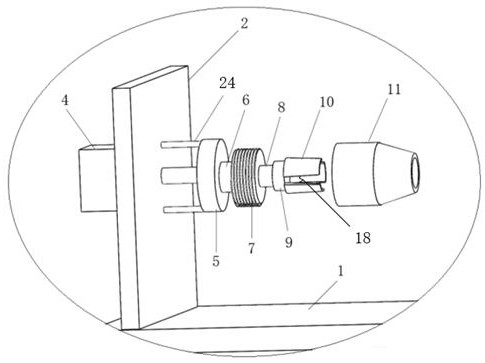

[0032] Such as Figure 1-4As shown, a physical grinding device for laboratory use includes a base 1, and the base 1 is provided with a first side plate 2 and a second side plate 3, and the board surface of the first side plate 2 and the second side plate 3 is arranged correspondingly, the first side plate 2 is provided with a cylinder 4, the rod of the cylinder 4 is connected with a clamping mechanism, and the clamping mechanism includes a first round platform 5, and the first round platform 5, one side is fixedly connected with the rod of the cylinder 4, and the other side is connected with a threaded platform 7 through the first connecting piece 6, and the side of the threaded platform 7 away from the first circular platform 5 is connected with the second connecting piece 8 through the second connecting piece 8. Two round tables 9, in order to make the clamping mechanism more stable, the first round table 5, the first connector 6, the threaded table 7, the second connector 8...

Embodiment 2

[0035] Same as Example 1, the difference is: as Figure 1-2 As shown, the bottom of the hood 16 is connected with a support column 19, and the end of the support column 19 away from the hood 16 is connected with a slider 20, and the base 1 is provided with a slideway matched with the slider 20. twenty one. By setting the support column 19 at the bottom of the machine cover 16, it is beneficial to support the weight of the second motor and the grinding wheel 17, preventing the grinding wheel 17 from shifting downward under the action of gravity and affecting the grinding effect; the support column 19 is slidably connected to the base through the slider 20 1, it is beneficial to cooperate with the left and right movement of the grinding wheel 17 when working.

Embodiment 3

[0037] Same as Example 1, the difference is: as Figure 1-2 As shown, the connecting rod 12 is a square structure, the upper end of the connecting rod 12 is connected with a guide plate 22, the guide plate 22 is L-shaped, and the second side plate 3 is provided with a 22 is matched with the guide groove 23, the length of the guide groove 23 is equal to the length of the rectangular frame 13, and the inner diameter of the guide groove 23 matches the outer diameter of the guide plate 22. By setting the L-shaped guide plate 22, and the L-shaped guide plate 22 cooperates with the guide groove 23 on the second side plate 3, it is beneficial to prevent the position deviation of the connecting rod 12 when moving in the horizontal direction, so that the structure of the device is more stable.

[0038] Working principle: a physical grinding device used in the laboratory. Under normal conditions, the bite mouth 11 is threadedly connected with the thread table 7. By loosening the bite mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com