Coupling disassembling device and coupling disassembling method

A coupling and half-coupling technology, applied in the field of coupling decomposing devices, can solve the problems of low operation safety and reliability, long maintenance time, etc., so as to improve operation safety, ensure safety, and operate conveniently and efficiently. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

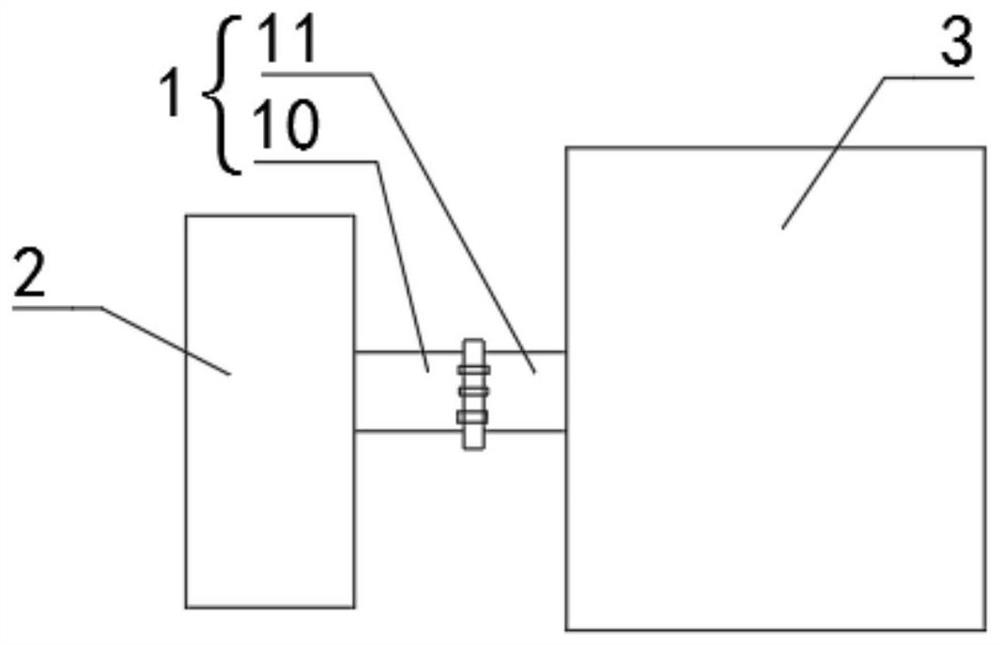

[0050] The coupling disassembly device provided in this embodiment is used to disassemble the coupling between the gear transmission device 3 and the motor 2 of a subway train. Usually the coupling includes a first half coupling 10 and a second half coupling 11 connected to each other by bolts, the first half coupling 10 is connected to the motor, and the second half coupling 11 is connected to the gear transmission 3 , so that the power on the motor side can be transmitted to the gear transmission side through the first half-coupling 10 and the second half-coupling 11 in sequence.

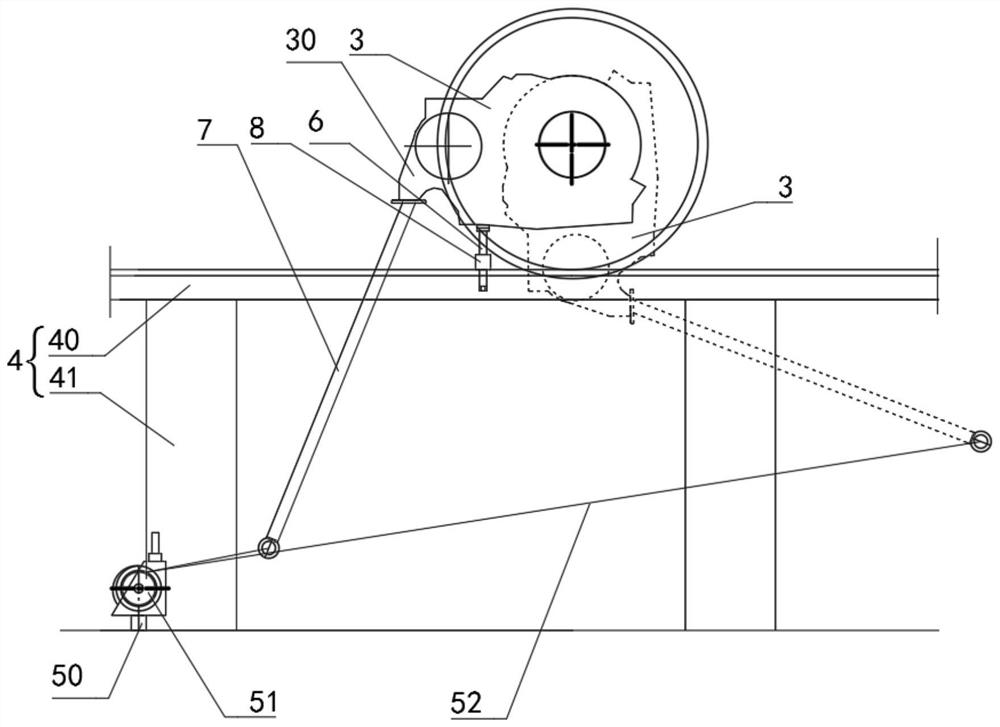

[0051] see Figure 1 to Figure 7 As shown, the coupling disassembly device provided in this embodiment includes an inspection track 4 , a traction mechanism 5 and a support mechanism 6 .

[0052] Hereinafter, the above-mentioned components of the coupling disassembly device will be described in detail.

[0053] In this embodiment, the overhaul track 4 is arranged outside the trolley track where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com