Container railway-waterway combined transport direct receive by truck/vessel three-dimensional continuous loading and unloading operation system and method

A container, vehicle and ship technology, applied in the field of continuous loading and unloading operation system of container rail-water intermodal transport vehicles and ships, can solve the problems of reducing the storage pressure of adjacent stations, reducing the workload of horizontal transfer of trucks, and achieving short-distance transportation costs and operating methods The method is flexible and changeable, and the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

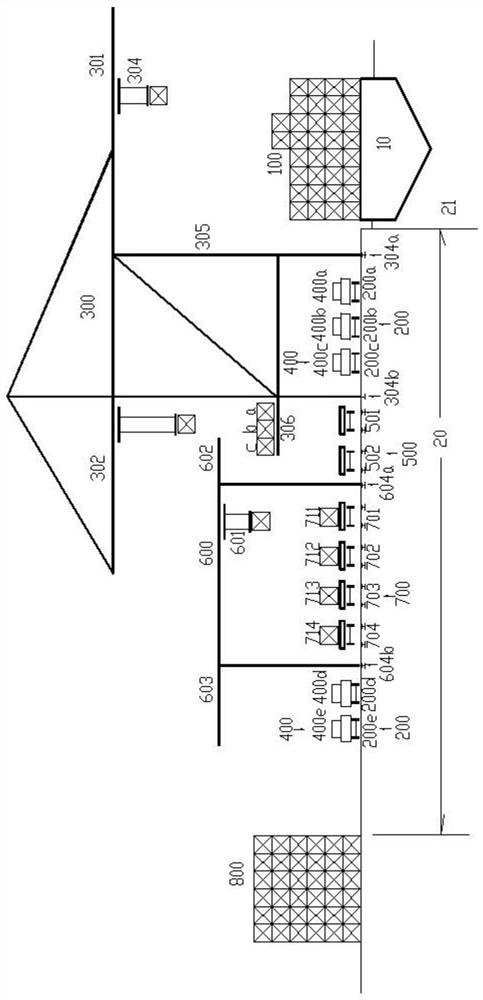

[0109] see figure 1 and figure 2 , the basic ship unloading railway loading vehicles and ships of the present embodiment directly get the continuous operation process (taking 1 railway loading and unloading line 701 as an example) as follows:

[0110] (1) Empty trains of railway containers According to the instructions issued by the railway container transportation management system, the empty railway vehicles 710 are sent by the station to the railway loading and unloading line 700 under the bridge of the gantry crane 600 through the railway locomotive.

[0111] (2) According to the operation plan, the quay crane grabs and lifts the water public transportation container 100 from the ship 10 to the quay crane 300 and collects the trucks 400a-400c, or transfers it to the rear cantilever 603 of the gantry crane through the container transfer platform 306 Collecting trucks 400d-400e, driving out of the terminal front 20 along the specified road route through the collecting truc...

Embodiment 2

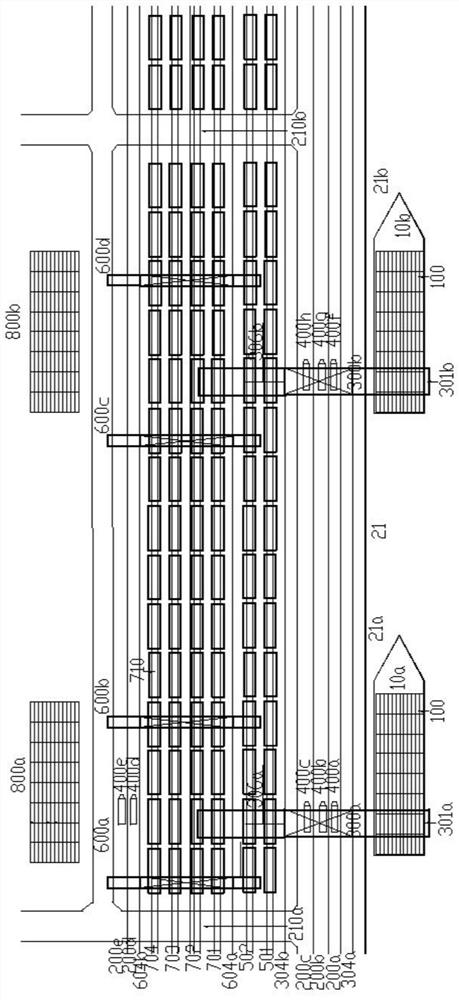

[0120] see image 3 , the basic ship unloading railway loading vehicle and ship of the present embodiment directly takes the continuous operation process (taking 2 railway loading and unloading lines as an example, but not limited to 2) as follows:

[0121] The information planning and dispatching of ships and railways in the front of this embodiment, as well as the combined arrangement and matching of ships, quayside cranes and gantry cranes, are the same as those in the first embodiment and will not be described again.

[0122] (1) Empty trains of railway containers According to the instructions issued by the railway container transportation management system, the empty railway vehicles 711 are sent by the station to the railway loading and unloading line 701 under the span of the gantry crane 600 through the railway locomotive.

[0123] (2) According to the operation plan, the quay crane 300 grabs and lifts the container 100 of the water-public transport from the ship 10 to...

Embodiment 3

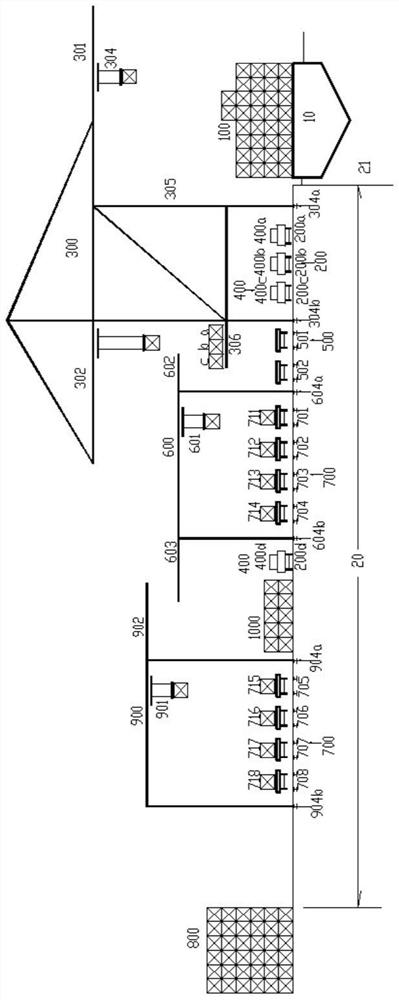

[0129] The basic railway unloading ship loading and unloading operation process of the present embodiment (taking 1 railway loading and unloading line as an example) is as follows:

[0130] (1) The station sends the railway loaded container heavy vehicle 710 to the railway loading and unloading line 700 or the railway storage line 500 under the gantry crane 600 through the railway locomotive.

[0131] (2) When the arrival time of heavy vehicles and empty ships can be matched, the gantry crane 600 lifts the container loaded on the railway vehicle 710, and directly transfers it to the container transfer platform 306 through longitudinal travel and lateral displacement. The platform 306 continues to lift the container at the transfer box position, the quay crane trolley and the spreader 304 run to the ship 10, unload the container on the ship 10, and complete the loading operation with one hook. After the quay crane trolley is put back, the cantilever waits for the next container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com