Totally-closed sound barrier with novel structure

A new type of structure, fully enclosed technology, applied in the direction of noise absorption devices, buildings, etc., can solve the problems of large transparent unit panels, unfavorable cleaning, complex on-site construction, etc., to facilitate installation and replacement, increase overall aesthetics, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

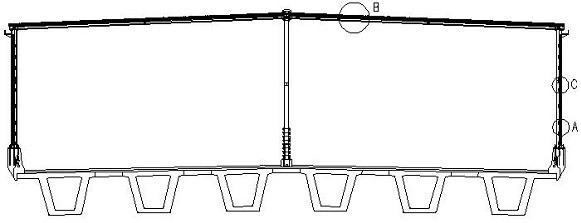

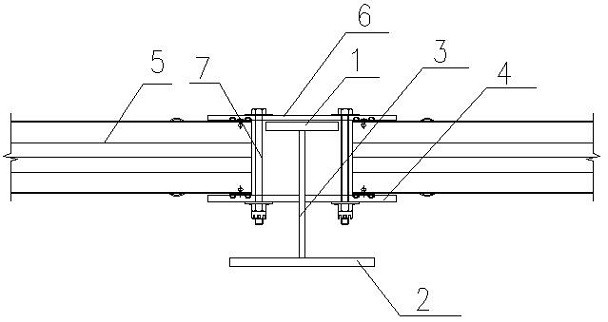

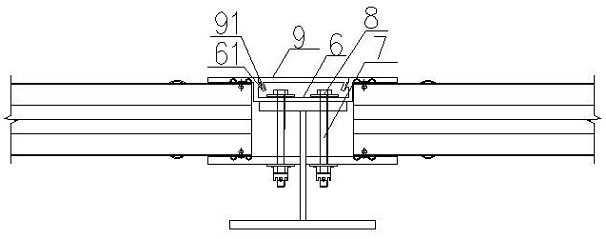

[0019] Such as figure 1 , 2 As shown, a fully enclosed sound barrier, which includes shaped steel and a sound-absorbing and insulating screen fixed on the shaped steel, the shaped steel includes upright part shaped steel on both sides and a roof that is fixedly connected to the upright part shaped steel on both sides Part of the section steel, the upright section of section steel and the roof section of section steel together form an inverted U-shaped structure. The sound-absorbing and insulating screen includes an upright section of screen and a roof section of the screen. The upright section of the screen is fixed on the upright section of the section steel. Above, the screen body of the roof part is fixedly arranged on the section steel of the roof part, and the opaque unit board 5, the transparent unit board 10 and the opaque unit board 5 are arranged up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com