Method for testing release flux of multi-component gas on surface of soil body

A technology of gas release and test method, which is applied in the direction of soil material testing and material inspection, and can solve the problems of decreasing concentration gradient, ignoring the diffusion interaction of multi-component gases, and not considering the multi-component mixed gas of landfill gas, etc. , to achieve good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

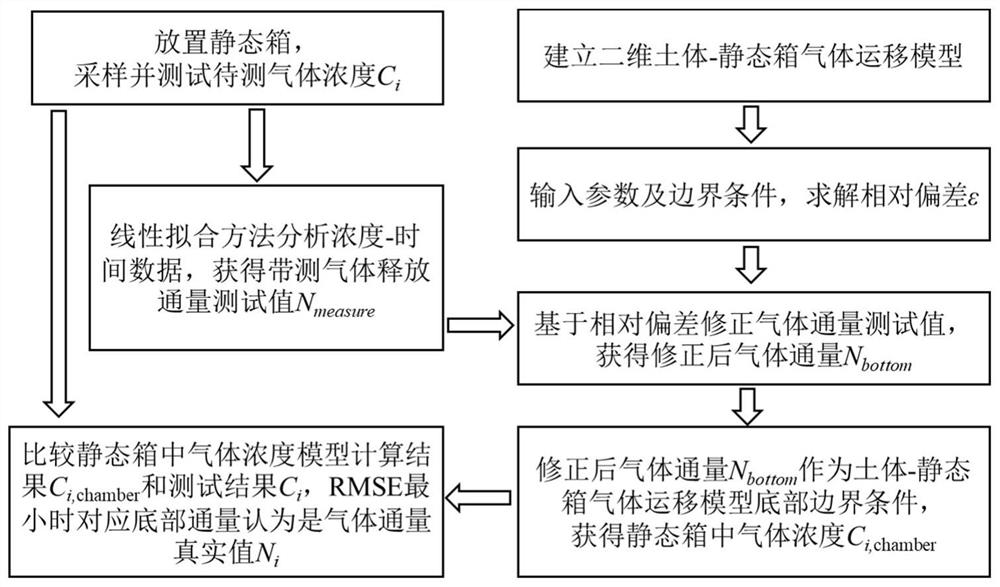

Method used

Image

Examples

Embodiment example 1

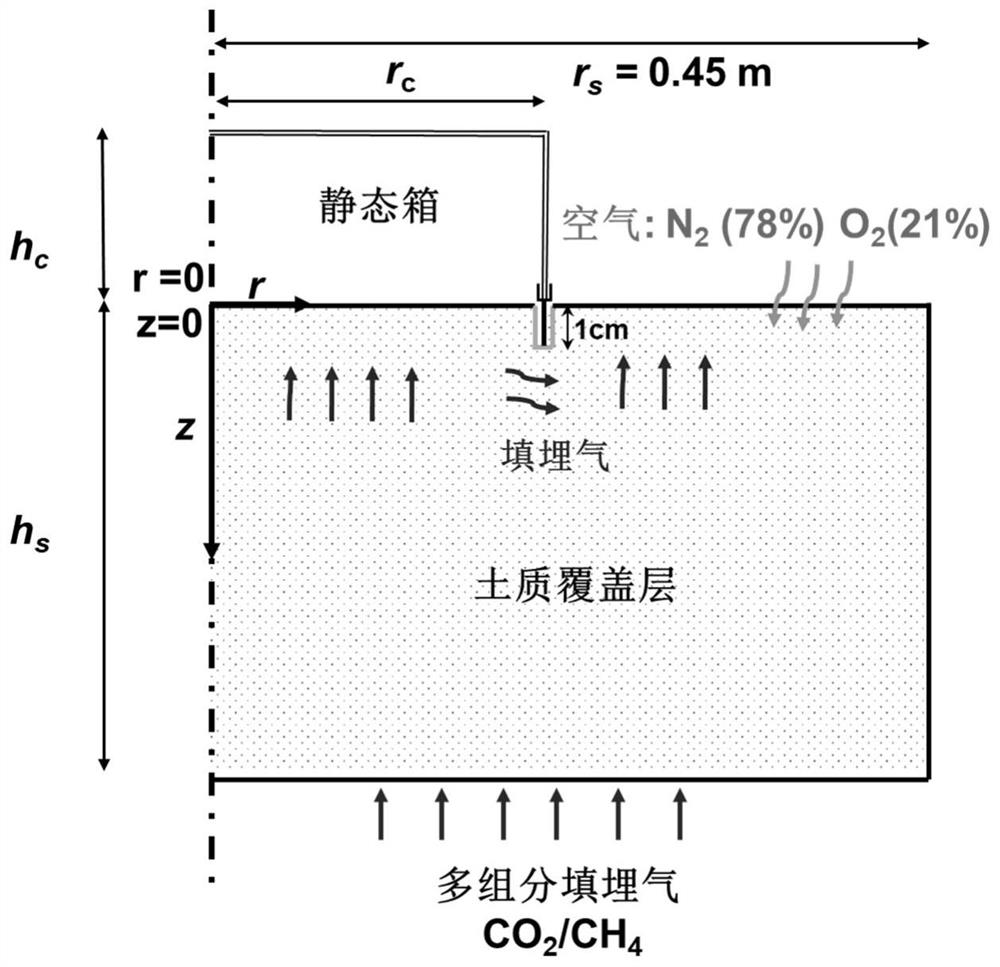

[0070] The present invention is verified by previous experimental data, and the experimental results are from Perera et al. (2002) and Senevirathna et al. (2007) (Figure 4). Perera et al. (2002) conducted a static chamber test in which CO was injected into the bottom of the soil column. 2 199g / m 2 / d, to test CO in static chambers of different sizes 2 concentration. The sizes of static boxes from small to large are: 0.1m×0.05m, 0.2m×0.12m, 0.25m×0.16m (diameter×height). The soil column has a diameter of 0.45m and a height of 0.8m. According to the established multi-component gas migration model, the CO in static boxes of different sizes was simulated after the static box was placed. 2 concentration. The parameter values are shown in Table 1.

[0071] In the static chamber experiment conducted by Senevirathna et al. (2007), the CH passing through the bottom of the soil column 4 and CO 2 The flux is 300g / m 2 / d. The concentration of each component gas in the area whe...

Embodiment example 2

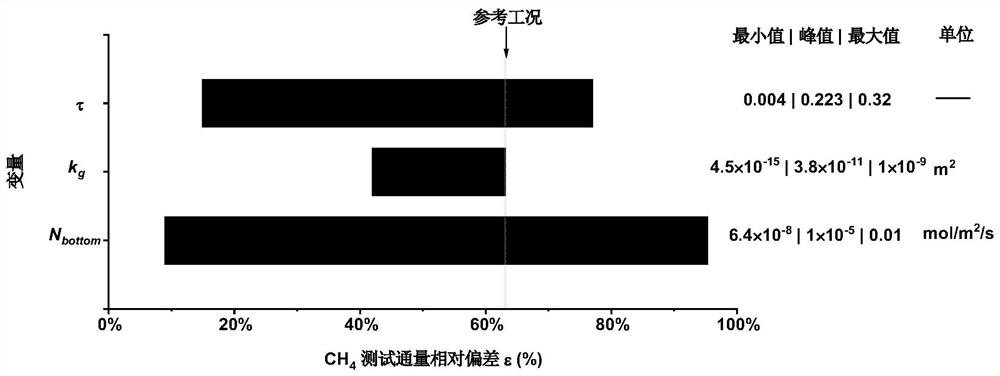

[0081] In this embodiment, a static box with a radius of 0.25m and a height of 0.55m is placed on the surface with loess as the covering layer, and the test corresponds to the CH in the static box at different times. 4 gas concentration. Through the test deviation analysis, assume the test error value and the tortuosity coefficient of gas diffusion. Correct the test flux and input the model to get the CH in the static box 4 concentration.

[0082] Step 1: Randomly select measuring points on the surface of the loess overburden of the landfill, and arrange static boxes. Press the base of the static box into the soil to a certain depth, and add water to seal it. Gas samples were collected at time 0, 15 min and 30 min respectively, and the gas samples were pumped into the Tedlar air bag through the sampling port on the top with a sampling pump. Take the gas bag back to the laboratory, inject 1mL of gas into the GC9800 analyzer with a syringe, and test CH 4 concentration. Eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com