Non-woven fabric mask and mask production process

A production process and non-woven technology, applied in the direction of sewing tools, clothing, clothing, etc., can solve the problems of inconvenient replacement of masks, not carrying replacement masks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

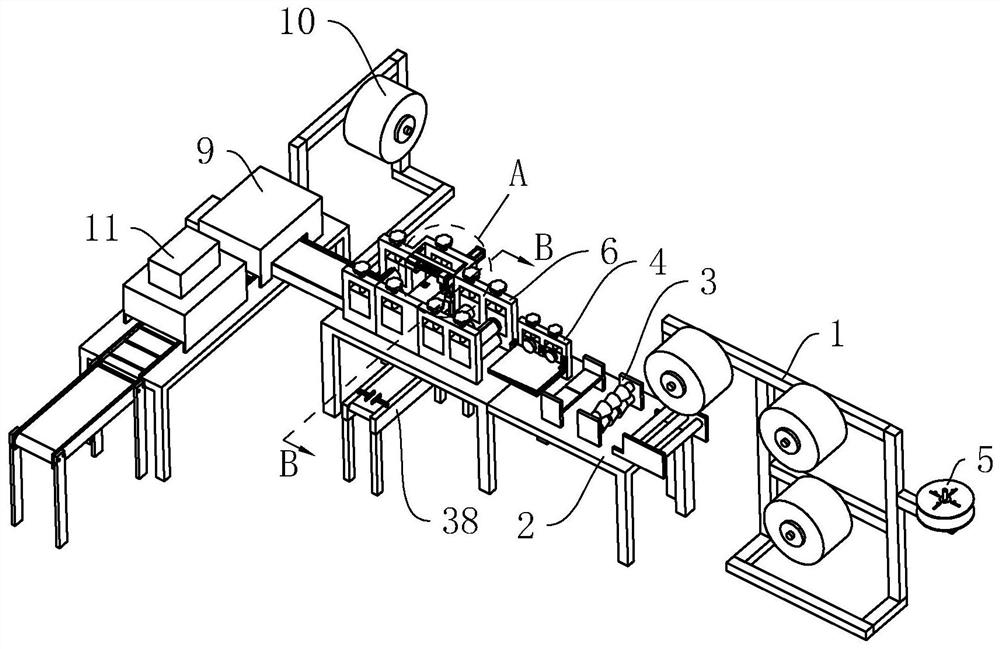

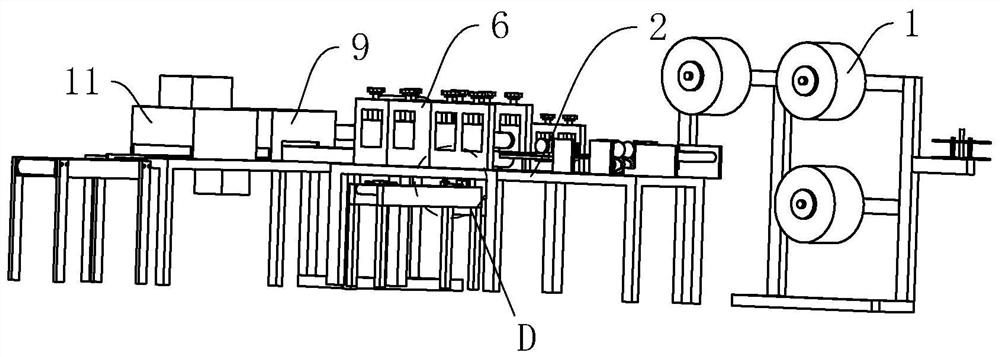

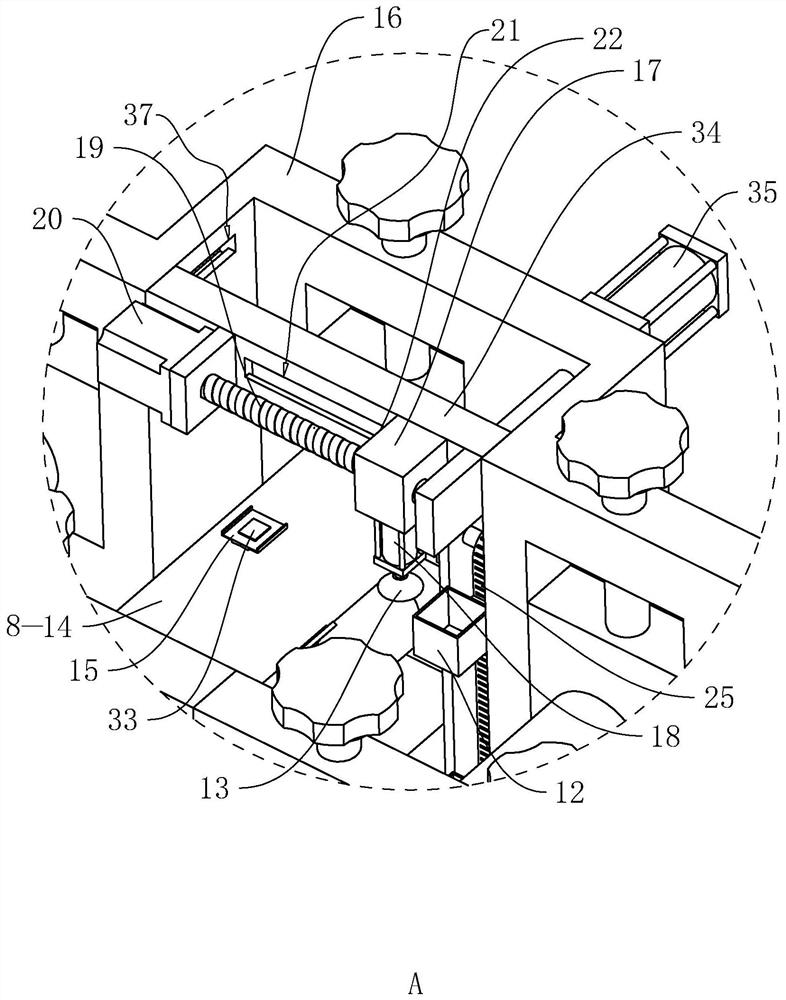

[0045]Contraction belowFigure 1-7Further detailed description of the present application.

[0046]The present application discloses a production process of a non-woven mask, including the following steps.

[0047]S1, cloth, the staff pulls the multilayer non-woven fabric from the cloth feed mechanism 1 to the machine 2;

[0048]S2, cloth prefusion: The fabric is completely flat from the fabric supply mechanism, into the fabric preparation mechanism 3, and fold the non-woven fabric, folding the folding portion;

[0049]S3, the nasal beam 41 cut: The nasal beam strip cutting mechanism 4 performs a crop number of the nose beam of the nasal beam feed mechanism 5, and the nasal beam 41 is wrapped in the non-woven fabric after the cutting of the nasal beam 41 is cleared.

[0050]S4, mask welding forming: mask welding forming mechanism 6 is thermocardly bonded around the nonwoven fabric wrapped with nasal beam strips 41;

[0051]S5, replacement bag 42 welding: The replacement bag conveying device 7 delivers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com