Screening equipment for elongated and flaky particles in aggregate

A technology of needle flakes and particles, which is applied in the direction of mechanical equipment, filter screens, grids, etc., can solve the problems of poor positioning effect, inconvenient material screening, inconvenient needle flake particle crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

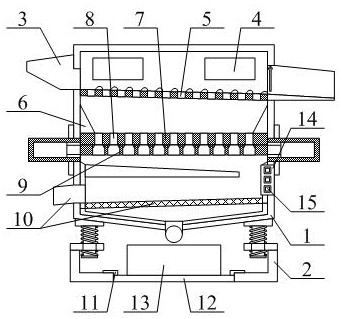

[0040] as attached figure 1 And attached Figure 4 shown

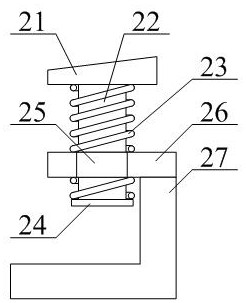

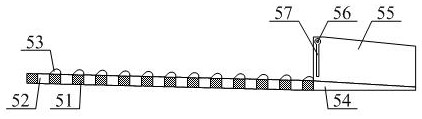

[0041]The present invention provides a device for screening needle-shaped flake particles in aggregate, including a screening frame 1, a buffer positioning frame structure 2, an introduction bucket 3, a vibration motor 4, a preliminary material export frame structure 5, a material guide plate 6, and a transverse plate 7 , guide hole 8, horizontal movable frame structure 9, powder finished product separation frame structure 10, L-shaped connecting plate 11, transverse plate 12, storage bucket 13, control panel 14 and control switch 15, the buffer positioning frame structure 2 Installed on the left and right sides of the lower part of the screen frame 1; the introduction bucket 3 is plugged into the upper left side of the screen frame 1; the preliminary material export frame structure 5 is installed on the inner upper part of the screen frame 1; The bolts of the guide plate 6 are installed around the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com