Municipal sewage pipeline unloading device

A technology for sewage pipes and unloading devices, which can be used in pipe cutting devices, water supply devices, sewer pipe systems, etc., and can solve problems such as human hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

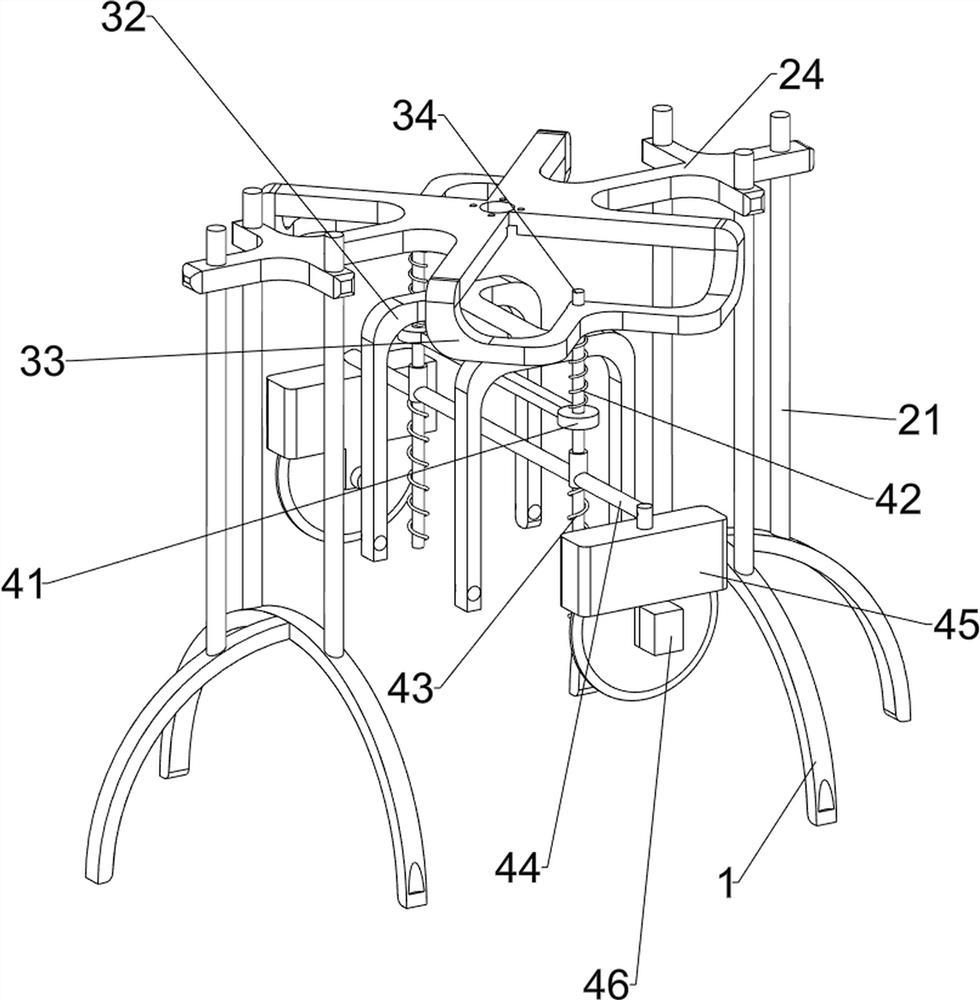

[0066] A municipal sewage pipeline unloading device, such as figure 1 As shown, it includes a support 1, a balance mechanism 2, a clamping mechanism 3 and a cutting mechanism 4, a balance mechanism 2 is provided between two supports 1, a clamping mechanism 3 is provided on the balance mechanism 2, and a clamping mechanism 3 is provided on the clamping mechanism 3. There are cutting mechanism 4.

[0067] When people need to unload the sewage pipeline, they can use this municipal sewage pipeline unloading device. First, people put the bracket 1 on the ground, and the balance mechanism 2 balances the bracket 1. Then people start the clamping mechanism 3, clamping The clamping mechanism 3 clamps the sewage pipe, and the movement of the clamping mechanism 3 drives the movement of the 4 parts of the cutting mechanism, so that the 4 parts of the cutting mechanism cut the sewage pipe, and close the clamping mechanism 3 when the clamping and cutting is not needed.

Embodiment 2

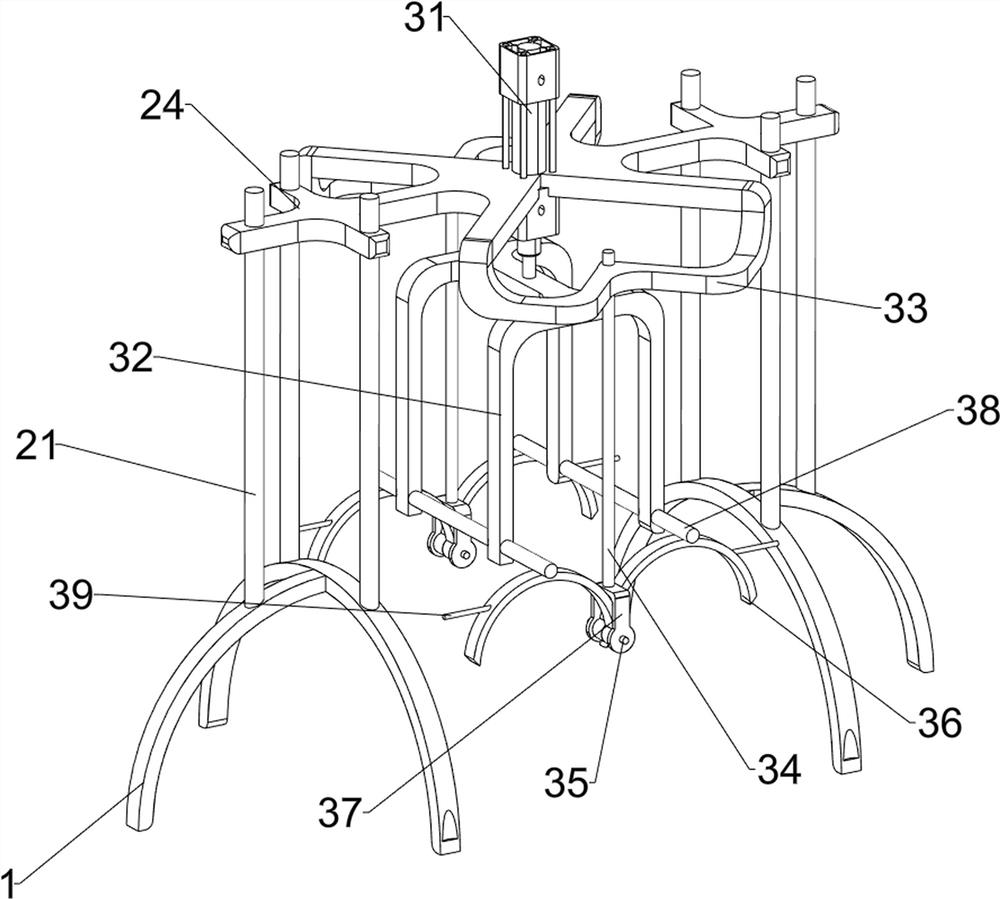

[0069] On the basis of Example 1, such as Figure 2-4 As shown, the balance mechanism 2 includes a fixed slide bar 21, a limit pin 22, a first spring 23 and a fixed plate 24, and three fixed slide bars 21 are arranged on the two brackets 1, and a limit pin is provided on the fixed slide bar 21. 22. A fixed plate 24 is slidably connected between the upper parts of the six fixed slide bars 21 , and a first spring 23 is connected between the fixed plate 24 and the limit pin 22 , and the first spring 23 is wound on the fixed slide bar 21 .

[0070] First, people put the support 1 on the ground on both sides of the sewage pipe. Due to the unevenness of the ground, the adaptive deformation of the first spring 23 drives the fixing plate 24 to maintain balance, which realizes the effect of resetting the support 1 .

[0071] The clamping mechanism 3 includes a cylinder 31, a fixed frame 32, a support frame 33, a fixed rod 34, a rotating rod 35, an arc clamp block 36, a first fixed block ...

Embodiment 3

[0076] On the basis of Example 2, such as Figure 5-7 As shown, a dust reduction mechanism 5 is also included. The dust reduction mechanism 5 includes a support block 51, a liquid storage tank 52, a catheter 53 and an atomizing nozzle 54. The left and right sides of the second fixed block 45 are provided with support blocks 51. A liquid storage tank 52 is arranged between the tops of the two support blocks 51 , and liquid guide tubes 53 are arranged symmetrically on the left and right sides of the liquid storage tank 52 , and an atomizing nozzle 54 is provided at the bottom of the guide tube 53 .

[0077] The water in the liquid storage tank 52 flows into the atomizing nozzle 54 from the liquid guide pipe 53, and sprays out from the atomizing nozzle 54, which realizes the effect of reducing dust.

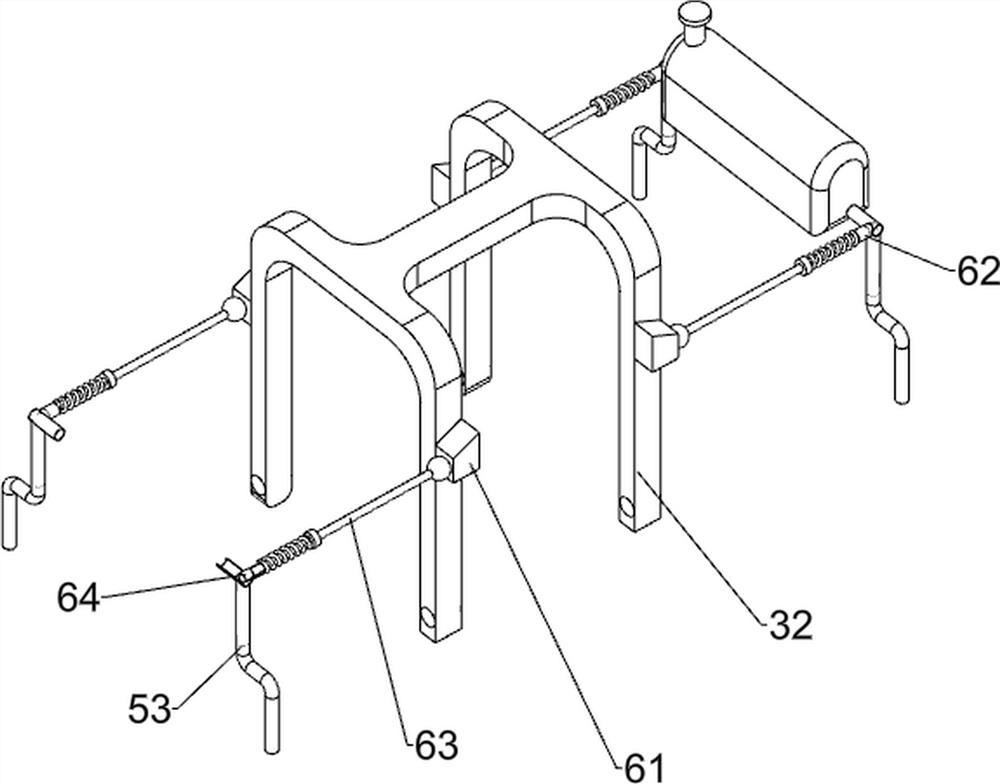

[0078] Also includes a water control mechanism 6, the water control mechanism 6 includes a wedge-shaped block 61, a fixed sleeve 62, an elastic assembly 63 and a water-stop block 64...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com