Chair back screw mounting machine

A technology for installing screws and chair backs, which is applied in the field of chair back installation screw machines, and can solve problems such as easy loosening of bolts, the separation of the chair back board from the chair back, and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

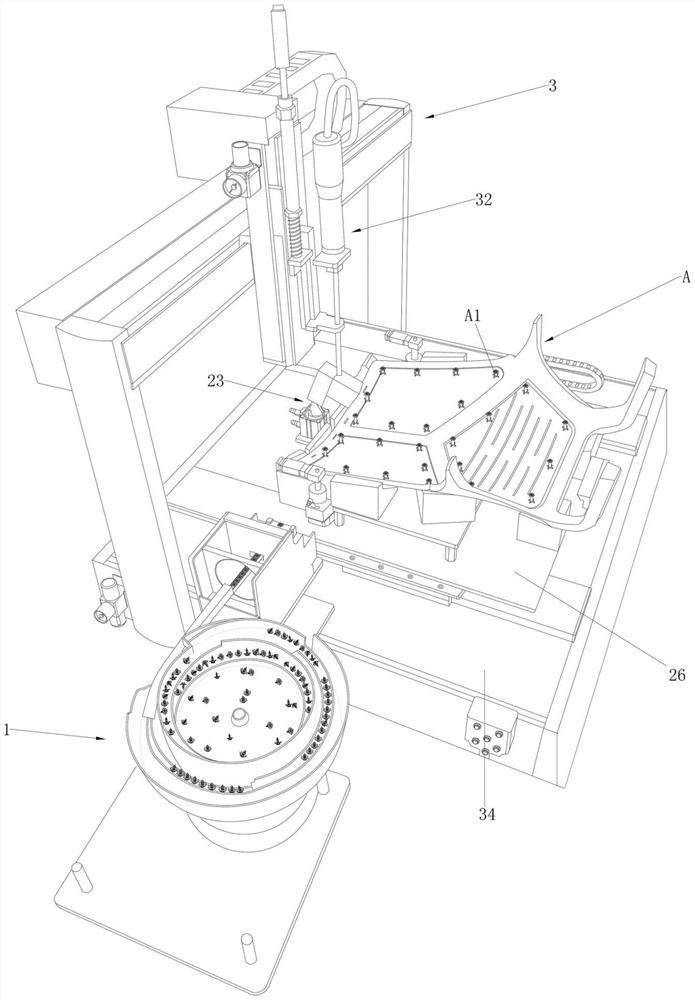

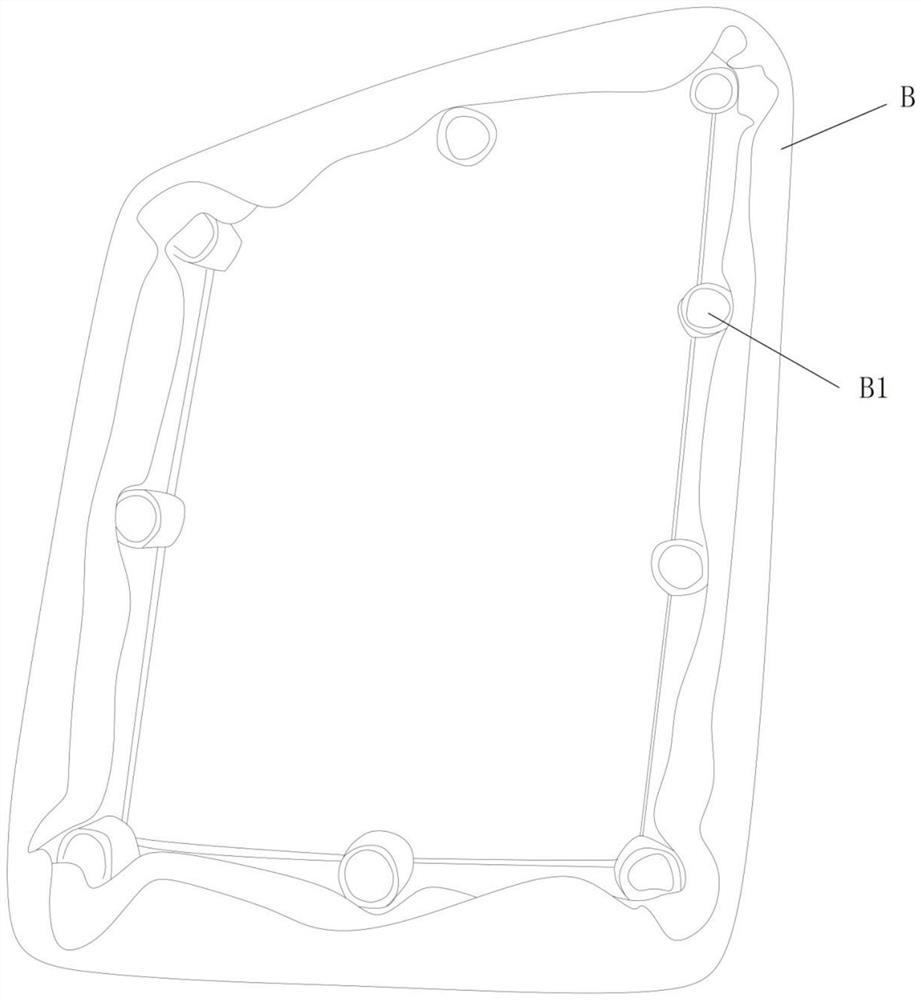

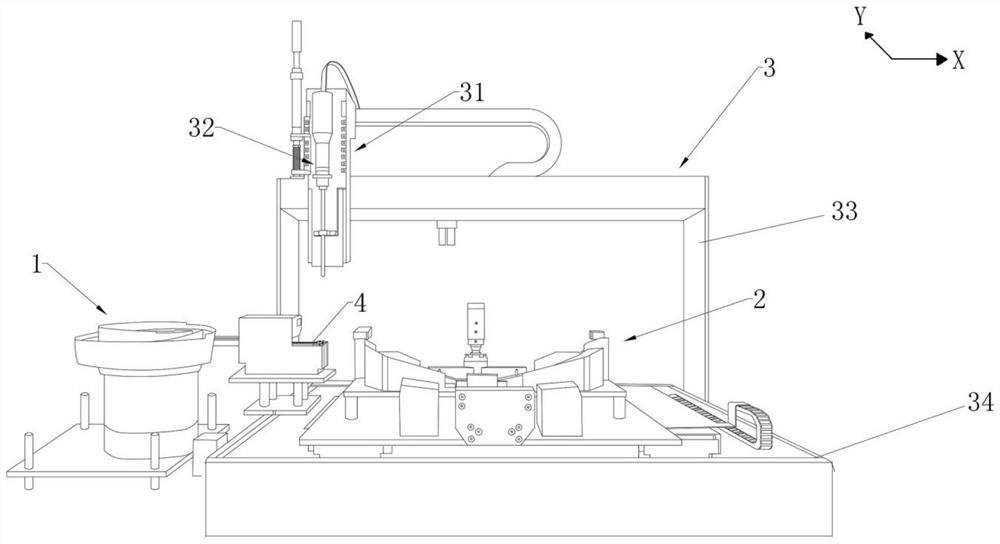

[0032] Referring to Fig. 1 to Fig. 1 of the accompanying drawings of the description of the present invention Figure 9As shown, according to a preferred implementation of the present invention, a screw machine for installing a chair back includes a screw feeding mechanism 1, a chair back clamping and fixing mechanism 2 and a manipulator assembly 3, and the chair back clamping and fixing mechanism 2 is located on the discharge track 13 Adjacent to the end, the manipulator assembly 3 includes a mounting frame and a manipulator 32 arranged on the mounting frame, a lifting arm 31 is slidably arranged on the mounting frame, and the manipulator 32 is disposed on the bottom of the lifting arm 31 , through the back and forth movement of the lifting arm 31 and the up and down driving of the manipulator 32 between the screw feeding mechanism 1 and the chair back clamping and fixing mechanism 2; the manipulator 32 grabs the screw 4 located in the screw feeding mechanism 1 and places it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com