Mortar tank for sand blasting derusting machine

A technology of sand blasting and rust removal, mortar tanks, applied in the field of mortar tanks, can solve the problems of difficult operation, high handle height and inconvenience for staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

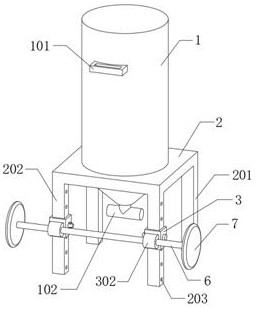

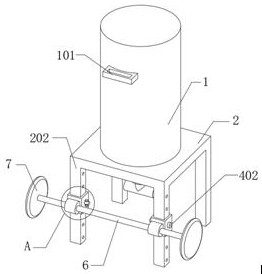

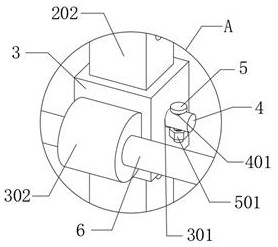

[0023] Embodiments of the present invention provide a mortar tank for sandblasting and derusting machines, such as Figure 1-5 As shown, the mortar tank main body 1 is included, the bottom of the mortar tank main body 1 is provided with a mortar outlet 102, the side wall of the mortar tank main body 1 is fixedly connected with a handle 101, and the bottom of the mortar tank main body 1 is fixedly installed with a support frame 2, and the support frame 2 includes The first leg 201 and the second leg 202, the quantity of the first leg 201 and the second leg 202 are two groups and symmetrically distributed at the bottom of the support frame 2, the side walls of the second group of legs 202 are Slidingly connected with sliding square tubes 3, two sets of sliding square tubes 3 are provided with locking components, the side walls of two sets of sliding square tubes 3 are fixedly connected with shaft sleeves 302, and the two sets of shaft sleeves 302 are internally connected with whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com