Cement stirring equipment for building construction

A technology for mixing equipment and building construction, which can be used in cement mixing devices, clay preparation devices, raw material supply devices for sale, etc., and can solve problems such as uneven mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

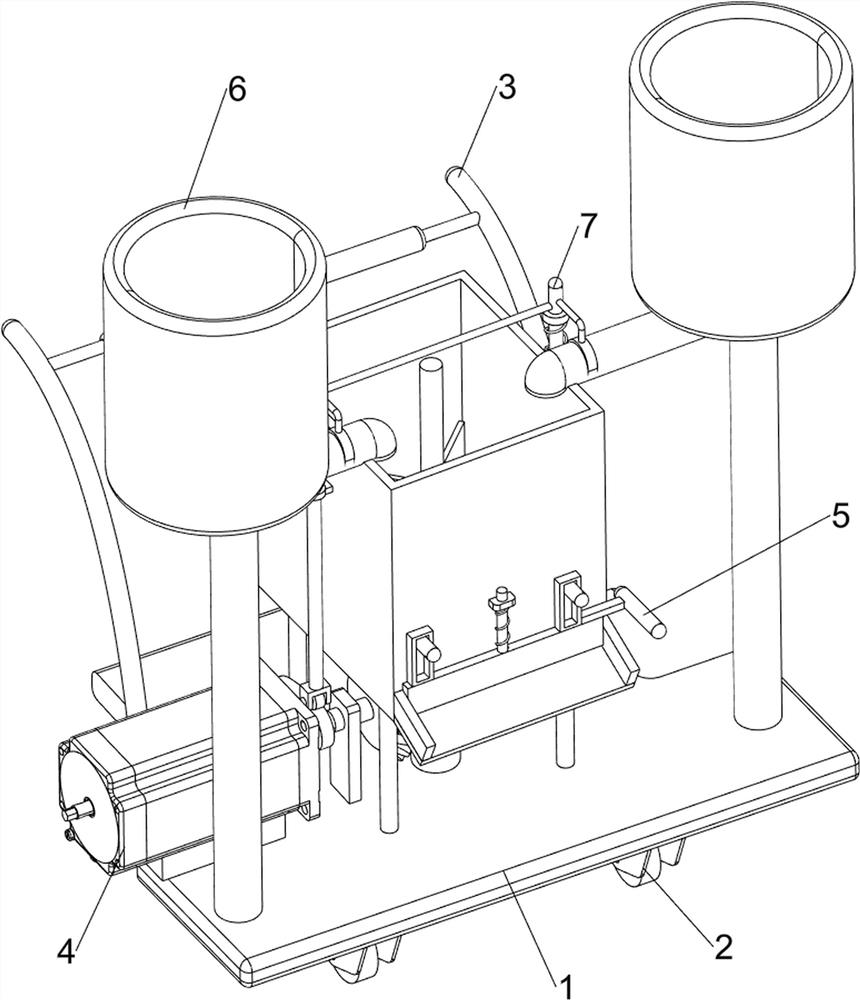

[0023] A kind of cement mixing equipment for building construction, such as Figure 1-4 As shown, it includes base plate 1, universal wheel 2, handrail 3, stirring mechanism 4 and discharge mechanism 5, the bottom of base plate 1 is provided with universal wheel 2, the front side of base plate 1 is provided with handrail 3, and the upper middle of base plate 1 is provided with A stirring mechanism 4 is provided with a discharge mechanism 5 on the stirring mechanism 4 .

[0024] When people need to mix the cement, they first push the handrail 3, and the handrail 3 drives the universal wheel 2 to rotate to move the device to the place where cement needs to be used, then put cement ash and water in the mixing mechanism 4, and start the mixing mechanism 4. The mixing mechanism 4 rotates to mix the cement evenly, and then people manually drive the discharge mechanism 5 to move, and people can use a container to connect cement under the discharge mechanism 5 for construction manufac...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 and Figure 5-7 As shown, a blanking mechanism 6 is also included, and the blanking mechanism 6 includes a first fixed rod 61, a material tank 62 and a material guide tube 63, and the left and right sides of the upper rear part of the base plate 1 are provided with a first fixed rod 61. The first fixing rod 61 is provided with a material bucket 62 , and the lower part of the material bucket 62 is provided with a material guide pipe 63 .

[0031] People can put cement ash and water into two material holding tanks 62 respectively, and cement ash and water can flow in the material holding box 43 through the feed pipe 63, so as to reach the purpose of carrying out feeding more conveniently.

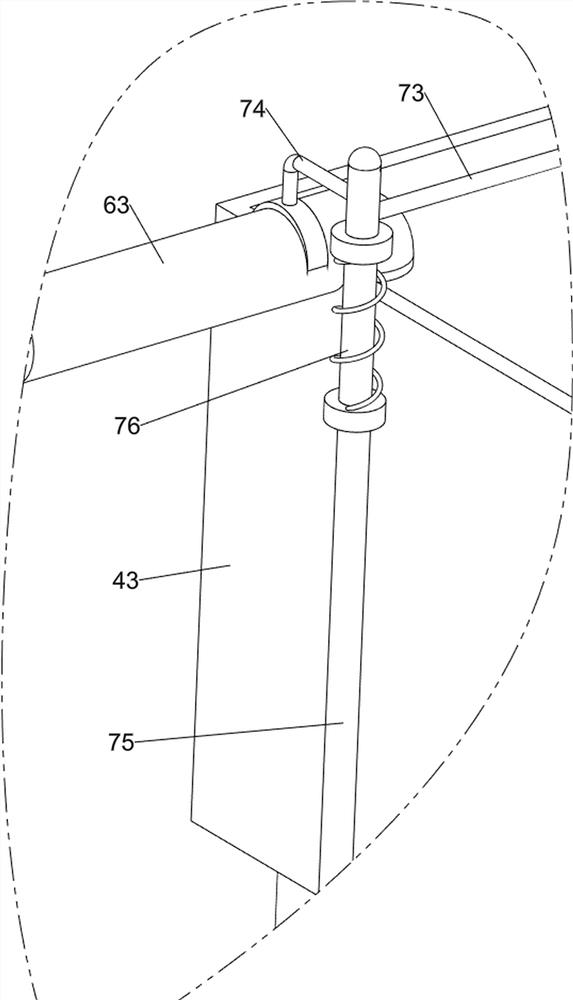

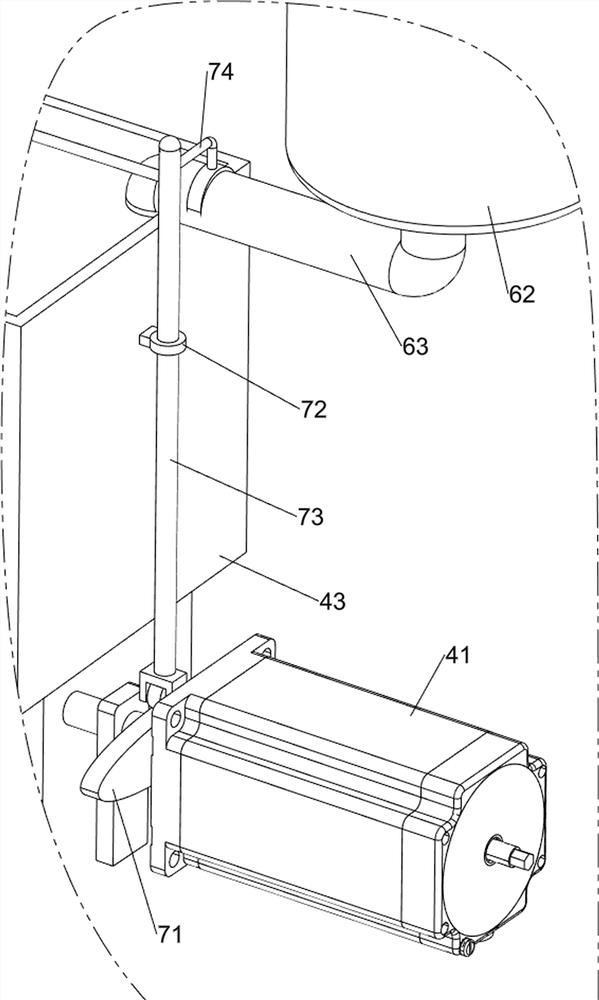

[0032] Also comprise material limiting mechanism 7, material limiting mechanism 7 includes cam 71, second fixed sleeve 72, second slide bar 73, material limiting plate 74, second fixed rod 75 and telescopic assembly 76, on the output shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com