Core pulling mechanism and elbow plastic processing mold using same

A core-pulling mechanism and a technology for processing molds, which are applied in household appliances, other household appliances, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

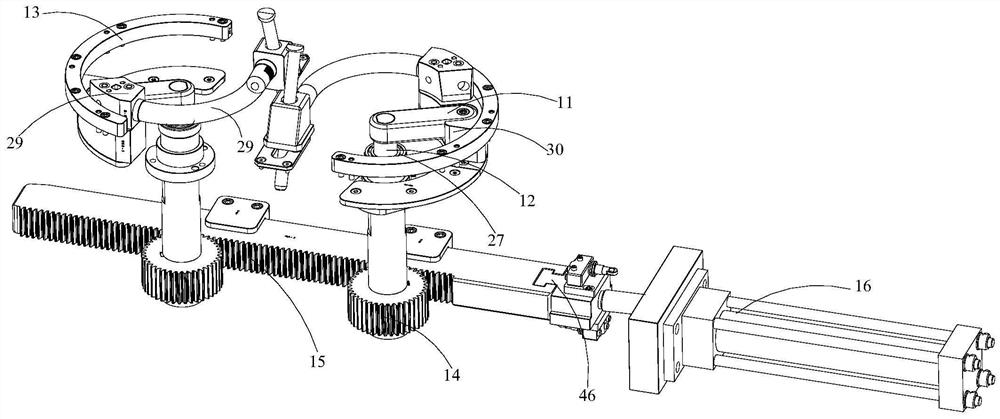

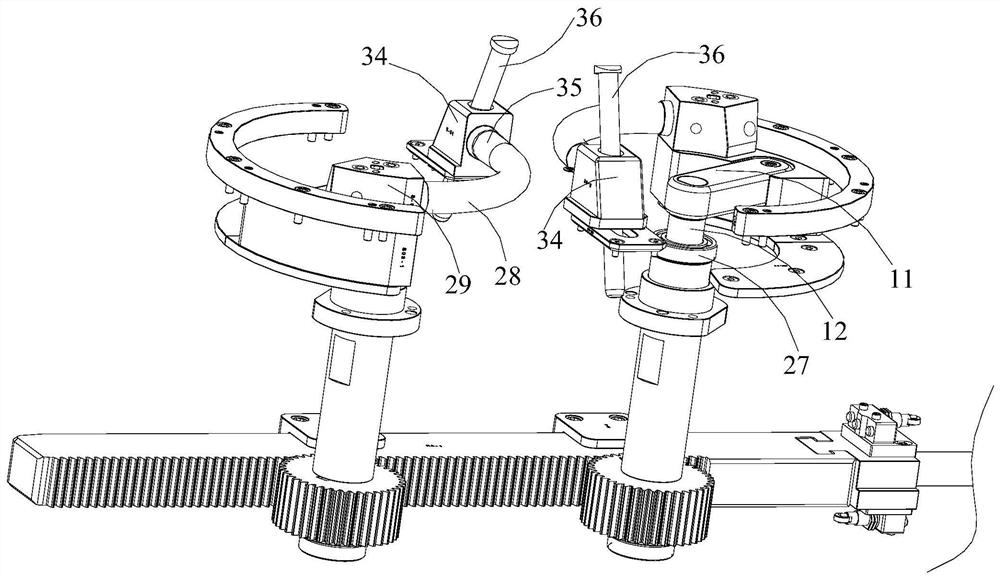

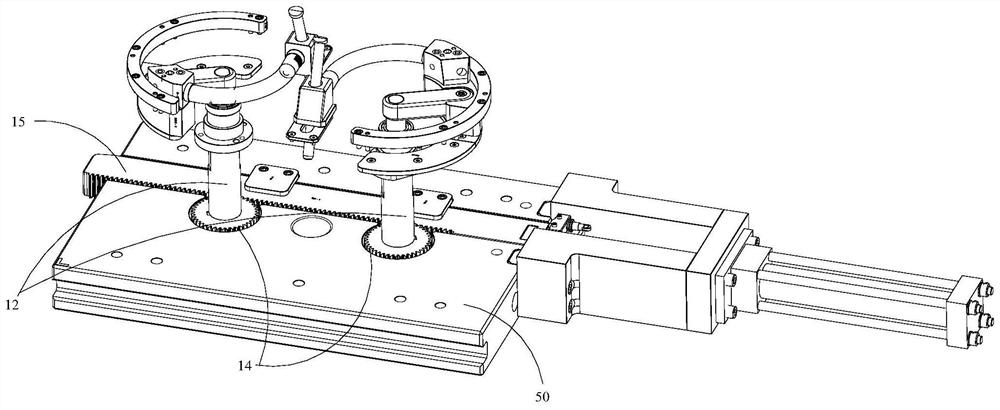

[0048] see Figure 1 to Figure 3 As shown, this embodiment provides a core-pulling mechanism, including: a pair of core-pulling assemblies arranged in mirror images, and a power assembly suitable for simultaneously driving a pair of core-pulling assemblies to run; wherein the core-pulling assembly includes a crank 11, and a crank 11 a rotating central axis 12 connected to one end, an elbow core-pulling connected to the end of the crank 11 away from the rotating central axis 12, and a core-pulling track 13 arranged outside the elbow core-pulling; the core-pulling track 13 used in this embodiment It is an arc structure, and the core-pulling track 13 of this arc structure is set in accordance with the specific shape of the bent pipe product 100, that is, for the bent pipe product 100, it is suitable for the bent pipe built into the bent pipe product 100 The core-pulling head must also be in an arc-shaped structure, so that the core-pulling track 13 with an arc-shaped structure ca...

Embodiment 2

[0051] see Figure 1 to Figure 9As shown, on the basis of the core-pulling mechanism in Embodiment 1, this embodiment provides a bending pipe plastic processing mold, including: a moving mold assembly and a fixed mold assembly used in conjunction, and in the moving mold assembly A core-pulling mechanism is provided; wherein the fixed mold assembly includes a fixed template 21 and a fixed mold kernel 22 arranged in the fixed template 21; the movable mold assembly includes a movable template 23 and a movable mold kernel 25 arranged in the movable template 23; And the fixed mold core 22 and the movable mold core 25 cooperate to form an injection molding cavity 26; the elbow core pulling part of the core pulling mechanism extends into the injection molding cavity 26. Specifically, for the injection molding cavity 26 suitable for forming the elbow product 100, the half structure of the injection molding cavity 26 is respectively provided in the fixed mold core 22 and the movable mo...

Embodiment approach

[0057] In an optional embodiment, a slider shovel base 37 is also provided at the end of the body part 34 of the slider away from the tubular insertion part 35, and the slider shovel base 37 can follow the slider along the inclined guide post 36. Synchronize movement during movement. In this embodiment, the set slider shovel base 37 is used to realize the limitation of the end of the slider away from the elbow core-pulling, so as to ensure the shaping of the elbow product 100 from the end away from the elbow core-pulling during the injection molding process of the product. , so as to effectively ensure the injection molding effect of the elbow product 100 .

[0058] In addition, during the movement of the slider along the inclined guide post 36 , in this embodiment, a slider guide rail 38 is provided on the end faces of the slider on both radial sides corresponding to the tubular insertion portion 35 to limit the movement of the slider. The track, that is, the sliding block i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com