Novel mildew-proof recombined bamboo based on pyrolytic tar-phenolic resin, and preparation method thereof

A technology of phenolic resin and phenolic resin glue, which is applied in the field of new anti-mildew recombinant bamboo and its preparation, can solve the problems of restricting large-scale promotion and application, affecting the use value and appearance, and prone to mildew, etc., so as to reduce dependence on petrochemical resources, Improve the utilization rate of raw materials and improve the effect of product cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

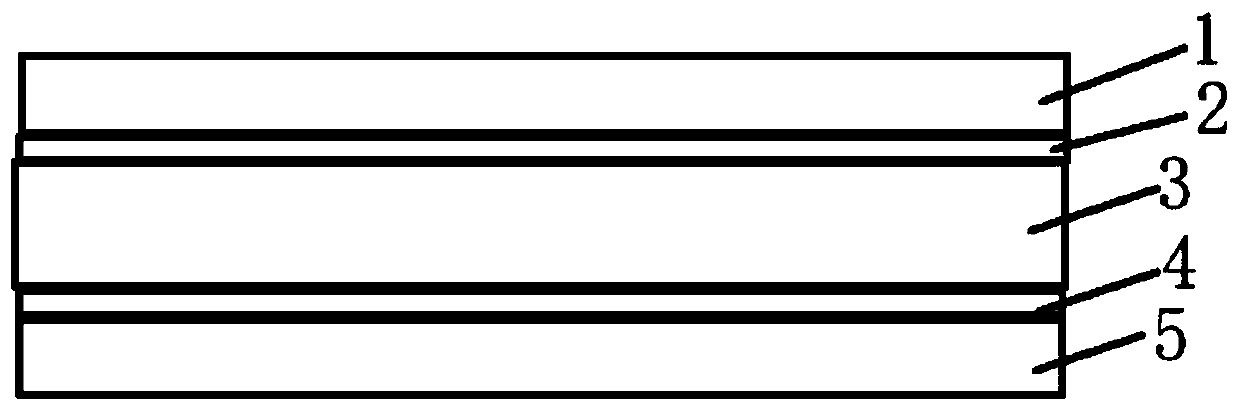

[0057] The application also provides a method for preparing an adhesive layer, said method comprising the steps of:

[0058] 1) Weighing resin synthesis raw materials such as phenol, formaldehyde, pyrolysis oil and sodium hydroxide solution according to a certain ratio.

[0059] 2) Add all the measured phenol, part of the formaldehyde solution (70% to 80% of the total mass) and part of the sodium hydroxide solution (40% to 50% of the total mass) into the synthesis reactor in sequence, and stir the reaction raw material mixture .

[0060] 3) Start the heating device, slowly and gradually raise the temperature of the mixture to (90±3)°C within 20 minutes, and keep it warm for 40-60 minutes;

[0061] 4) Start the cooling device, cool the mixed solution to 75°C, add the remaining formaldehyde solution (20%-30% of the total mass), pyrolysis oil and sodium hydroxide solution (25-30% of the total mass);

[0062] 5) Slowly raise the temperature of the mixture to (90±3)°C within 10-1...

Embodiment 1

[0081] (1) Bamboo bunch preparation: take moso bamboo as raw material, cut the original bamboo of moso bamboo into a certain length of bamboo tube, then longitudinally split it into two semicircular bamboo tubes along its diameter, and remove the inner section; , Cross-linked with each other and maintain the original arrangement of the fiber network loose bundle unit.

[0082] (2) Thermal cracking and liquefaction of bamboo residues: crush and dry the bamboo processing residues such as bamboo chips and bamboo shreds produced during the raw bamboo preparation process, crush until the particle size is less than or equal to 40 mesh, and dry until the moisture content is less than 5% ; The dried bamboo particles are thermally cracked and liquefied in a fluidized bed pyrolysis reactor, the reaction conditions are: reaction temperature (500 ± 10) ° C, gas phase residence time ≤ 2s, condensation temperature ≤ 4 ° C, the collected Bamboo pyrolysis oil is refrigerated for standby, bamb...

Embodiment 2

[0093] (1) Preparation of bamboo bundles: using Cizhu as raw material, the original bamboo of Cizhu is cut into a bamboo tube of a certain length, then longitudinally divided into two semicircular bamboo tubes along its diameter, and the inner section is removed; It is a network-like loose bundle unit that is cross-linked and maintains the original arrangement of fibers.

[0094] (2) Thermal cracking and liquefaction of bamboo residues: crush and dry the bamboo processing residues such as bamboo chips and bamboo shreds produced during the raw bamboo preparation process, crush until the particle size is less than or equal to 40 mesh, and dry until the moisture content is less than 5% ; The dried bamboo particles are thermally cracked and liquefied in a fluidized bed pyrolysis reactor, the reaction conditions are: reaction temperature (520 ± 10) ° C, gas phase residence time ≤ 2s, condensation temperature ≤ 4 ° C, the collected Bamboo pyrolysis oil is refrigerated for standby, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com