Energy conversion device and vehicle

An energy conversion device and bridge arm technology, applied in the field of vehicles, can solve problems such as poor compatibility, achieve the effect of good compatibility and reduce the cost of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present disclosure will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present disclosure, but not to limit the present disclosure.

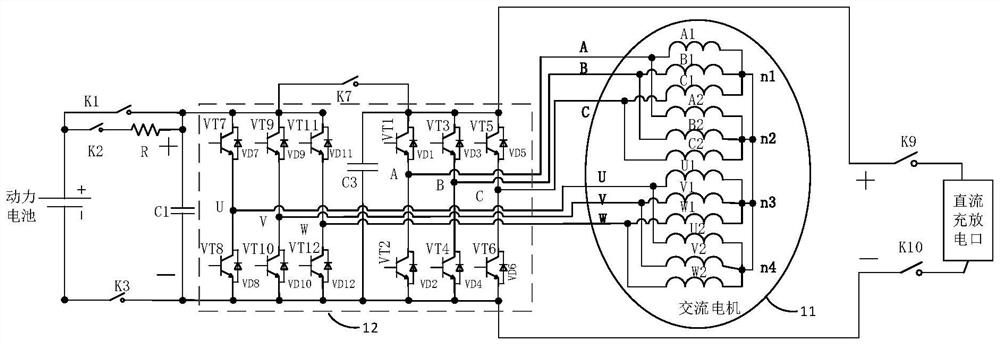

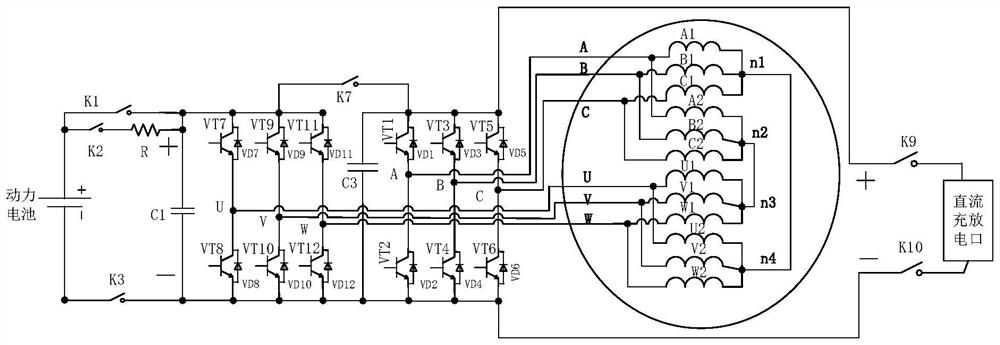

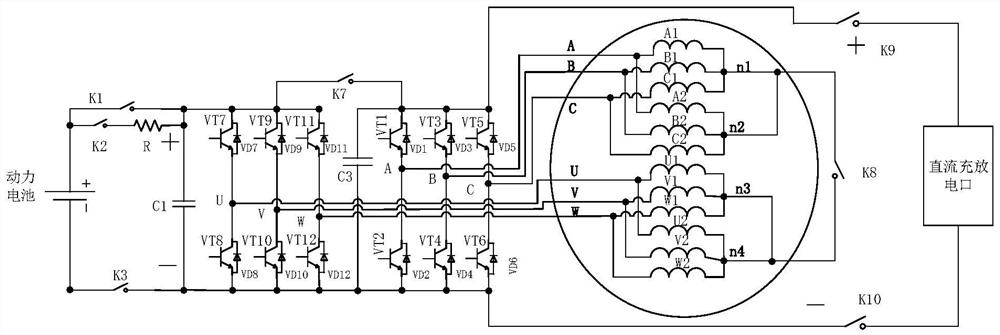

[0029] figure 1 A schematic structural diagram of an energy conversion device according to an embodiment of the present disclosure is shown. like figure 1As shown, the energy conversion device includes an AC motor 11, a bidirectional PWM inverter 12 and a switch module, wherein: the AC motor 11 includes x sets of windings, and all phases and windings of each set of windings can be controlled by the motor vector. The AC motor is running, and each set of windings is staggered by a certain electrical angle θ, where 2≤x, 0≤θ<360; the bidirectional PWM inverter 12 includes x groups of bridge arms, and each group of bridge arms is in phase with one of the sets of windings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com