Front-drive crawler tractor

A tractor and front-drive technology, applied to tracked vehicles, motor vehicles, steering mechanisms, etc., can solve the problems of increasing the weight of the whole machine, the length of the gearbox, and the difficulty of arranging auxiliary facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

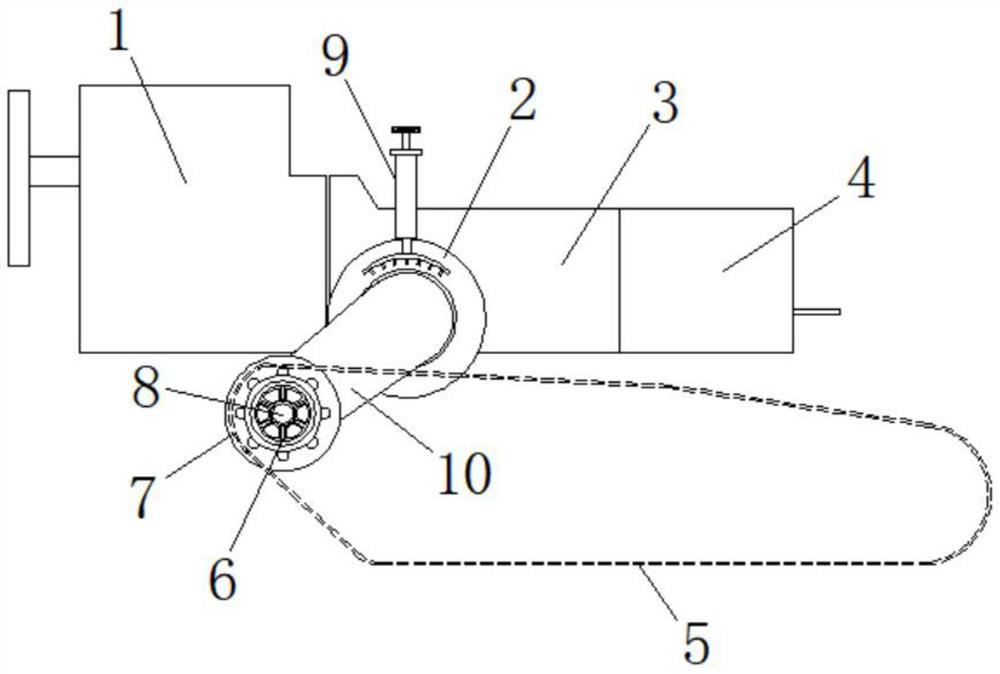

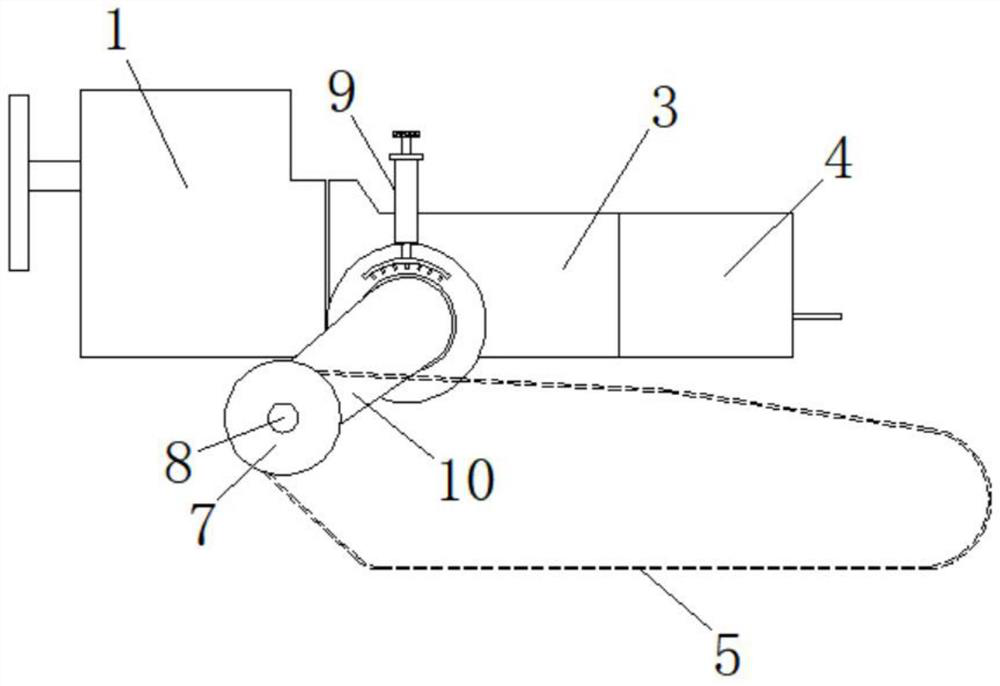

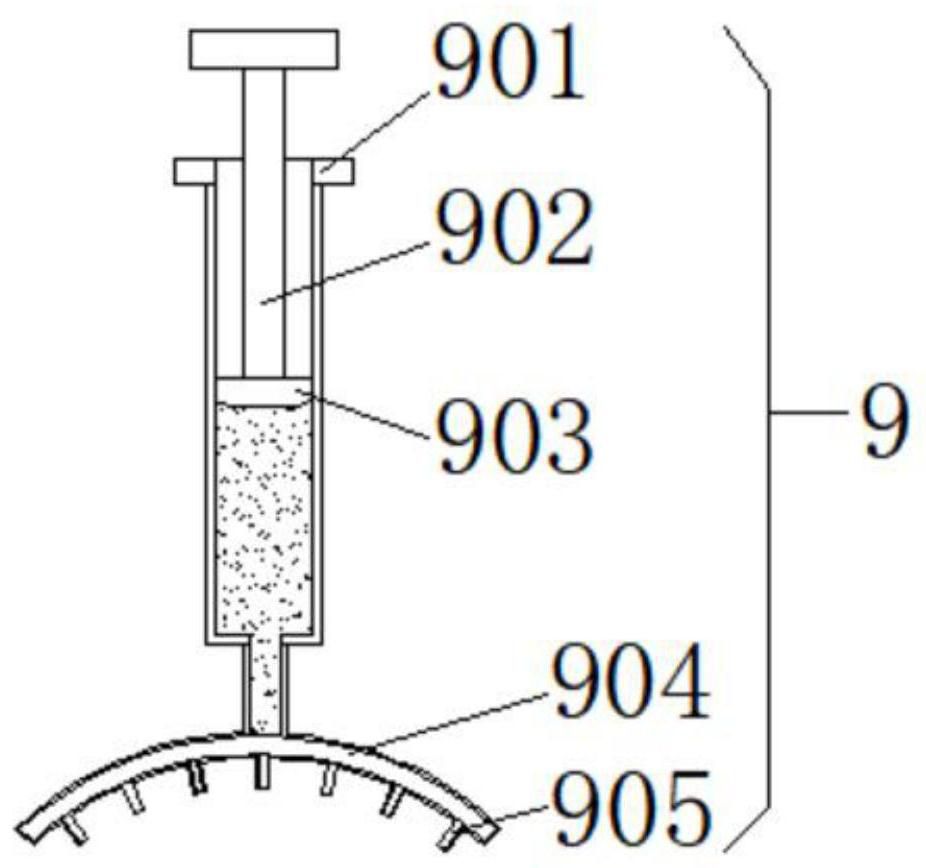

[0020]SeeFigure 1-3, The present invention provides a front drive track tractor, including the power source 1, one side of the power source 1 is provided with a transmission front end 3, and a gearbox rear end 4 is provided on one side of the gearbox front end 3. The bottom portion of the front end 3 side is configured with a steering mechanism 2, and the inside of the steering mechanism 2 is provided with a universal transmission shaft 10, and the bottom portion of the universal transmission shaft 10 is provided with a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com