Fat emulsion canning equipment for neurosurgery department

A canning equipment and neurosurgery technology, applied in the field of fat emulsion canning equipment for neurosurgery, can solve the problems of expensive equipment, slow canning speed, complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

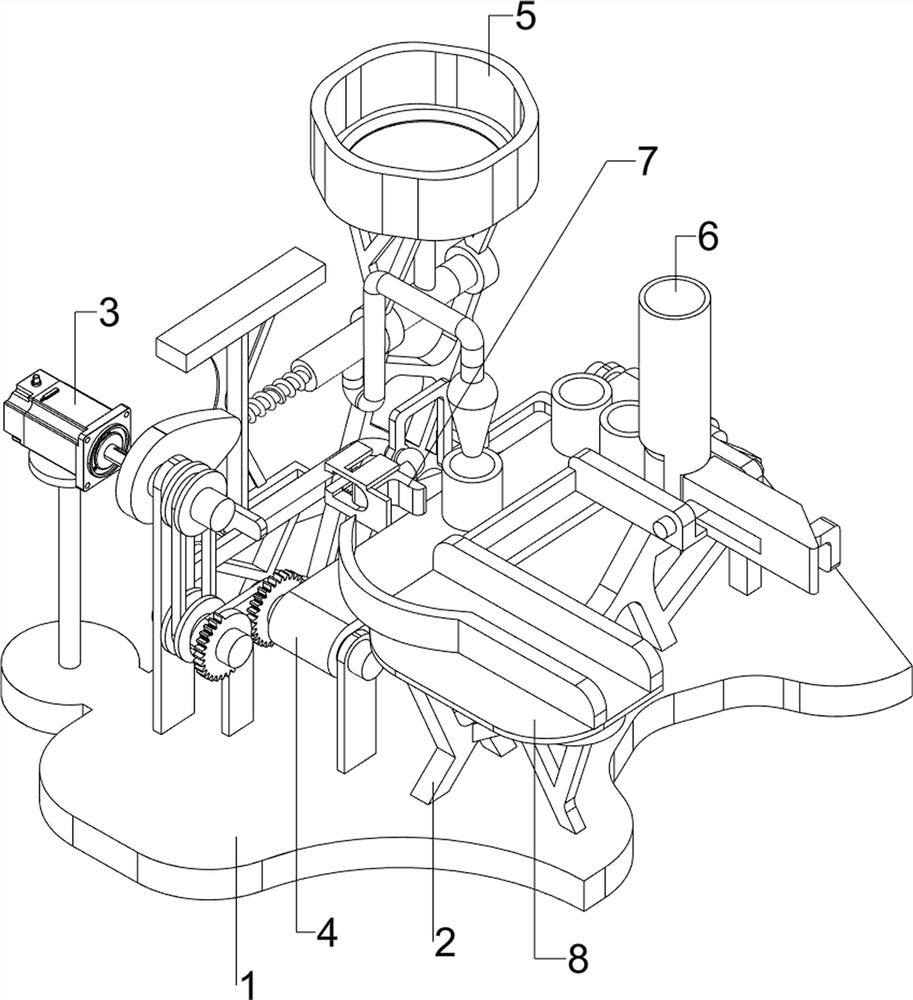

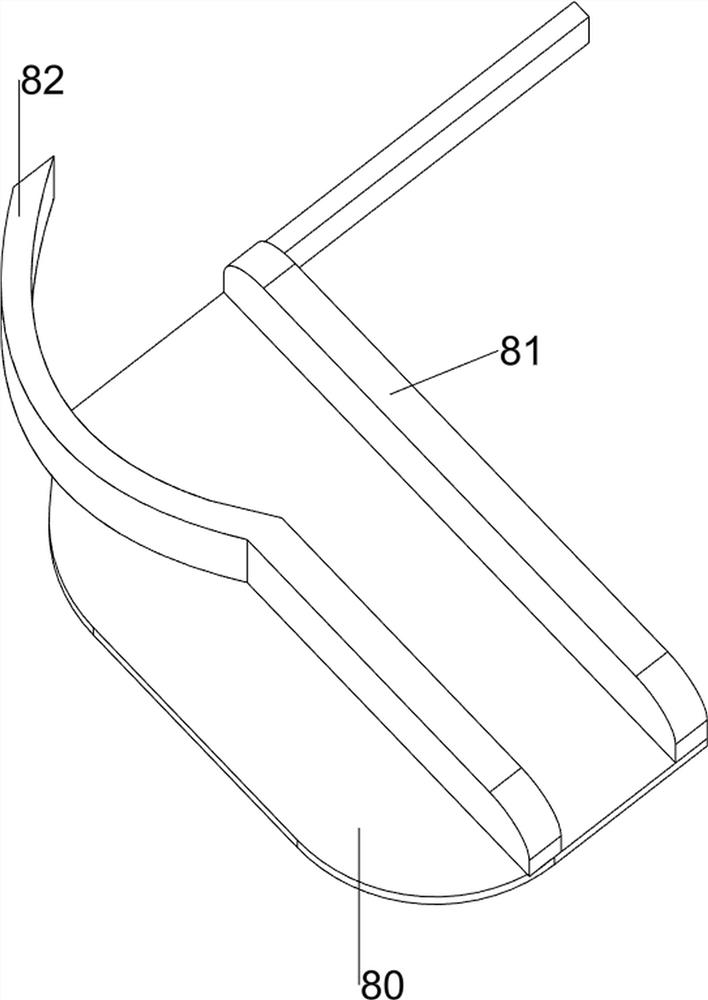

[0065] A kind of fat emulsion canning equipment for neurosurgery, such as figure 1 As shown, it includes a bottom plate 1, a placement frame 2, a canning mechanism 3 and a transportation mechanism 4, the bottom plate 1 is provided with a placement frame 2 on both sides, and a canning mechanism 3 is provided between the bottom plate 1 and the rear portion of the frame 2. A transport mechanism 4 is provided between the bottom plate 1 and the canning mechanism 3 .

[0066] When people need to can the fat milk, the material is placed on the transportation mechanism 4, the fat milk is placed in the canning mechanism 3, and then the canning mechanism 3 is started, and the canning mechanism 3 drives the transportation mechanism 4 to move, so that the transportation While the mechanism 4 transports the materials, the canning mechanism 3 cans the materials. After the canning is completed, the canning mechanism 3 is closed, and the transport mechanism 4 stops moving, and people can take...

Embodiment 2

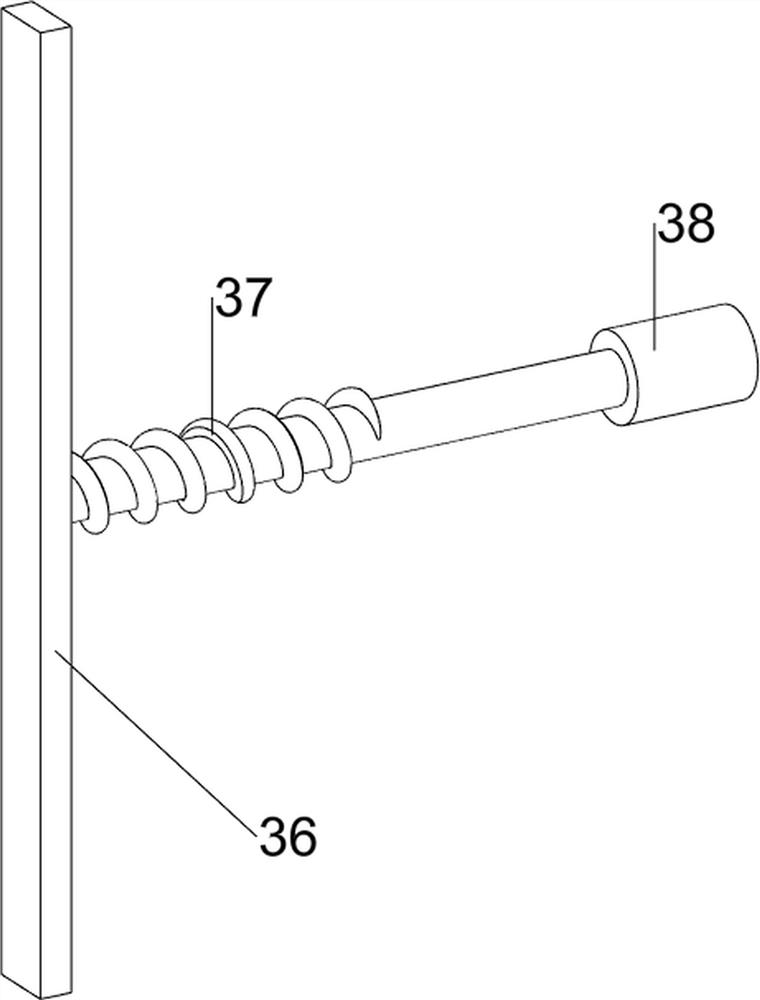

[0068]On the basis of Example 1, such as Figure 2 to Figure 8 As shown, the canning mechanism 3 includes a servo motor 30, a first bearing seat 31, a first rotating shaft 32, a cam 33, a first bracket 34, a first slide rail 35, a first connecting plate 36, a first spring 37, a piston Rod 38, sleeve 39 and fat emulsion discharge pipe 310, base plate 1 left rear part is provided with servo motor 30, base plate 1 left rear part is provided with first bearing seat 31, first bearing seat 31 upper part is rotatably connected with first Rotating shaft 32, the first rotating shaft 32 is connected with the output shaft of servo motor 30, the first rotating shaft 32 rear portion is provided with cam 33, the rear portion placing frame 2 left side is provided with first support 34, first support 34 both sides are provided with The first slide rail 35, the first connecting plate 36 is slidably connected between the first slide rail 35, the first connecting plate 36 is in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com