Push type blanking device

A push-type, feeder technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as unstable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

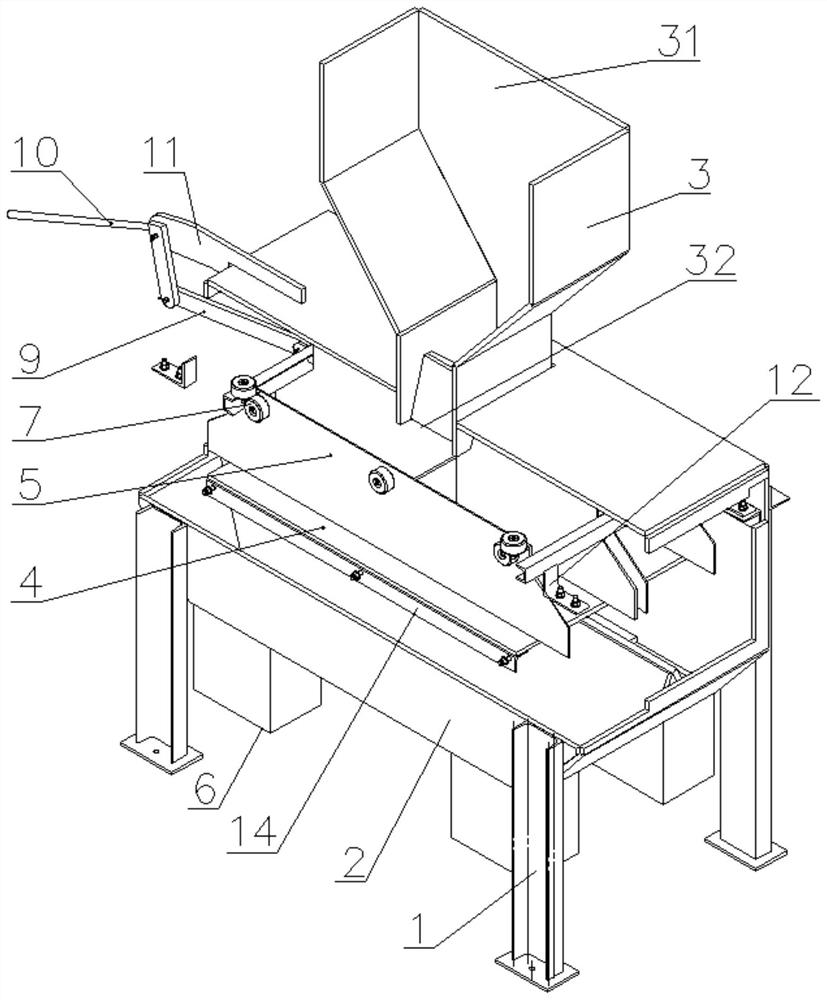

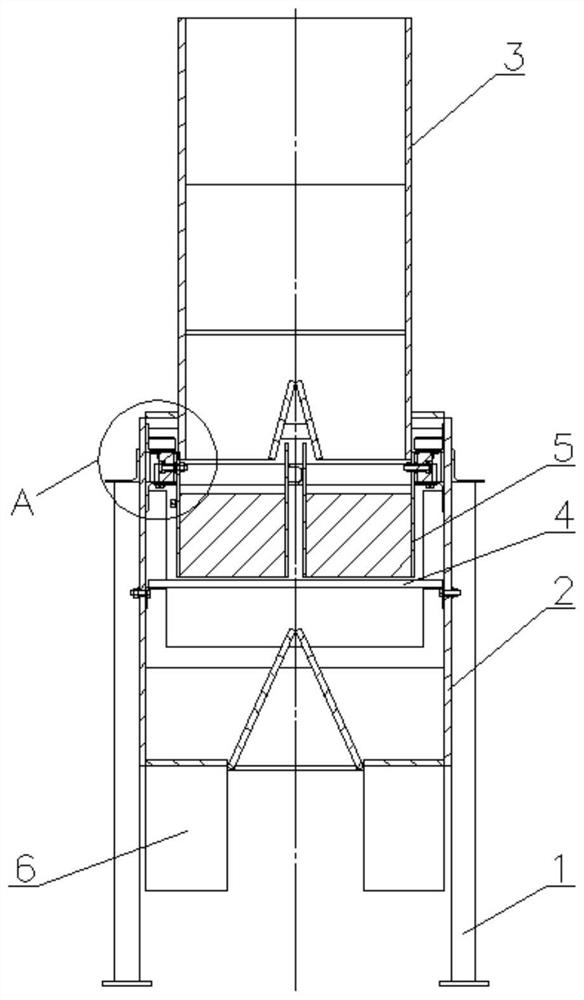

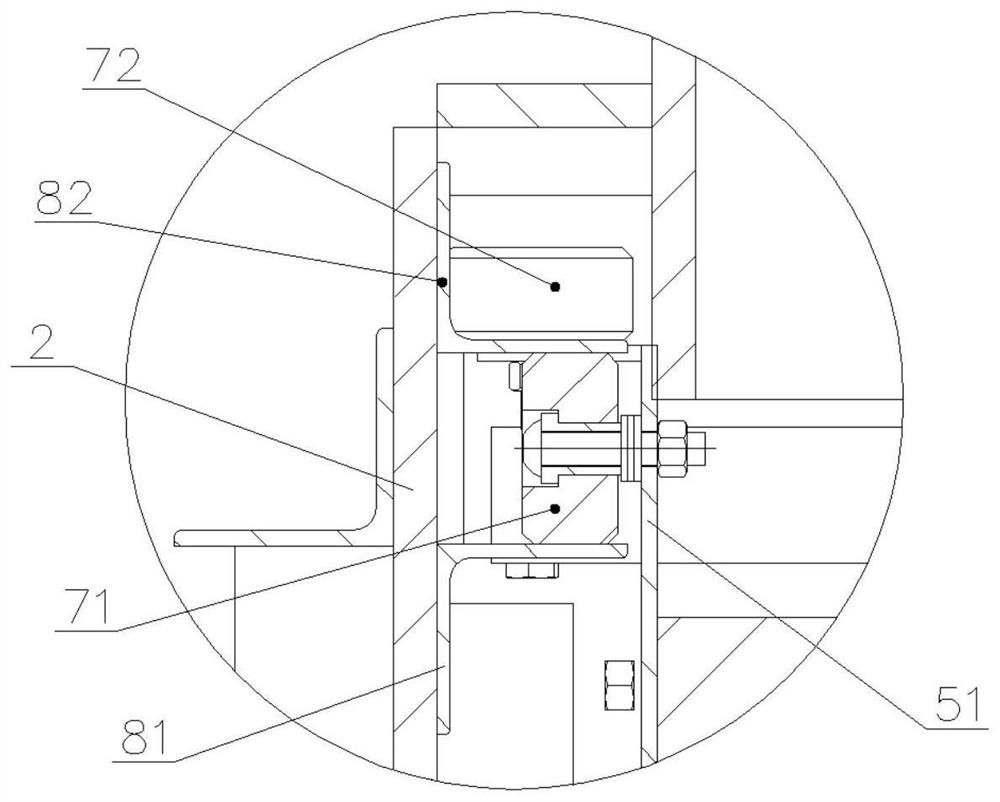

[0024] Such as Figures 1 to 7 As shown, the embodiment of the present invention provides a push-type feeder, including a plurality of pillars 1, a first shell 2 is fixed on the upper side of the pillars 1, and a second shell is fixed on the upper side of the first shell 2 body 3, the upper end of the second housing 3 is provided with a feeding port 31, the lower end of the second housing 3 goes deep into the first housing 2, and the lower end of the second housing 3 is provided with some material distribution ports 32, from The material 15 that enters through the feeding port 31 can dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com