Pretreatment system and method for deep purification of coke oven gas

A technology for coke oven gas and deep purification, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, and removal of gas pollutants, which can solve problems such as compressor blockage, increased operating costs, and impact on the stable operation of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

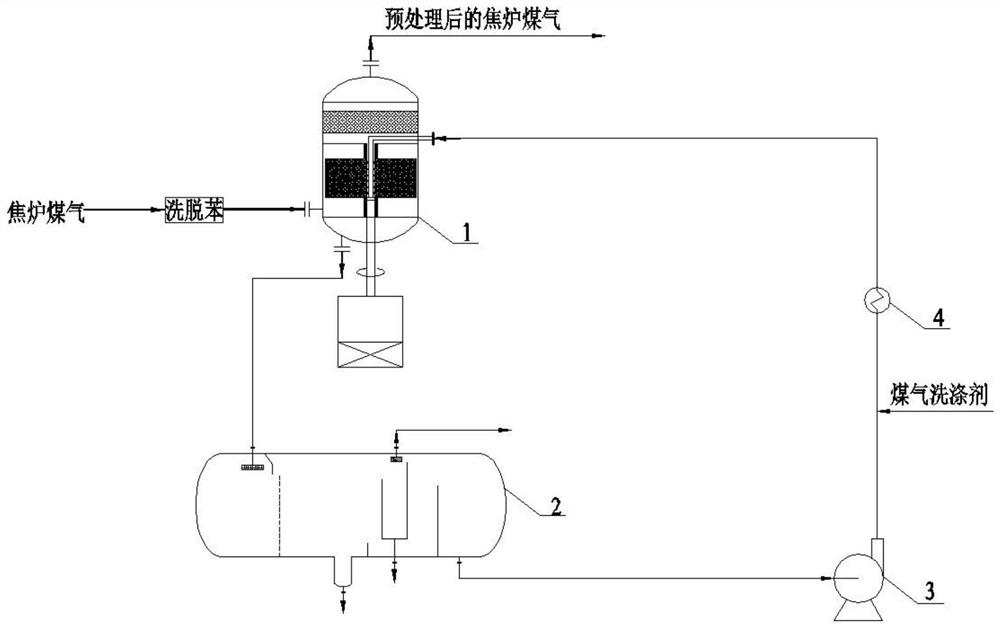

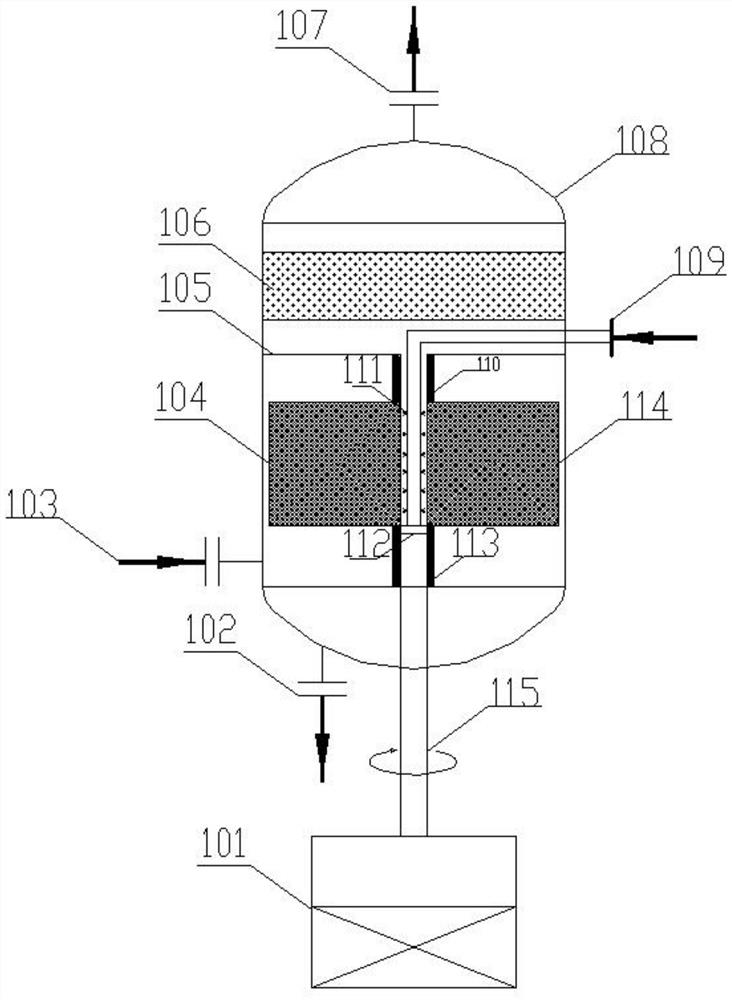

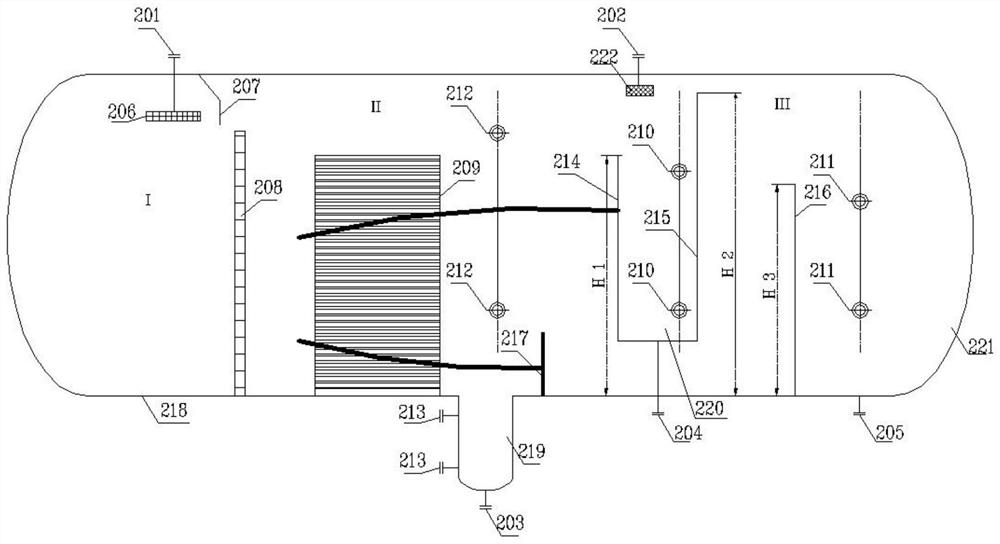

[0030] Such as figure 1 As shown, the embodiment of the present invention provides a pretreatment system for deep purification of coke oven gas, which includes a pre-washing tower 1, a four-phase separator 2, a circulation pump 3 and a heat exchanger 4, and the pre-washing tower 1 is High-gravity rotating device, the four-phase separator 2 is a horizontal three-weir type gas-liquid-liquid-liquid separator, wherein: the gas phase inlet 103 of the pre-washing tower 1 is connected to the coke oven gas pipeline after the benzene has been eluted, and the pre-washing The liquid phase outlet 102 of the tower 1 is connected with the feed port 201 of the four-phase separator 2, the intermediate phase fluid outlet 205 of the four-phase separator 2 is connected with the liquid inlet of the circulation pump 3, and the liquid outlet of the circulation pump 3 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap