Steel slag flue gas treatment method and system

A treatment system and treatment method technology, which is applied in the treatment method and system field of steel slag flue gas, can solve the problems of steel slag dust exceeding the standard and failure to meet the national ultra-low emission standard, and achieve good dust removal effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

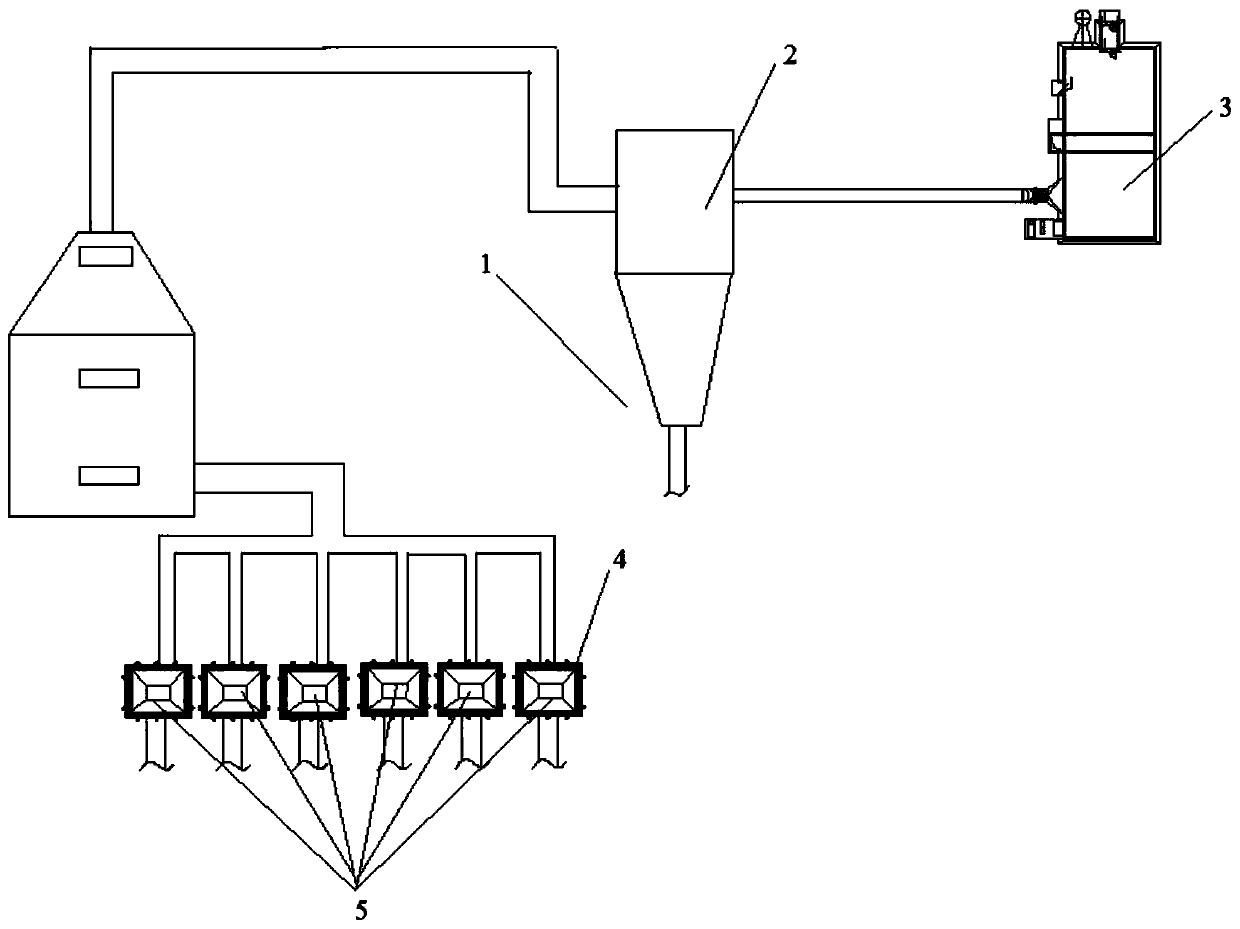

[0043] 1 spray tower 1 1

[0044] Cylinder diameter: D5000

[0045] Cylinder height: ~18m

[0046] Main material: Q235 steel

[0047] Number of spray guns: 10

[0048] Water supply: 1240t / h

[0049] Water supply pressure: 0.4~0.6MPa

[0050] 2 dehydrator 2 1 set

[0051] Cylinder diameter: D5000

[0052] Cylinder height: ~15m

[0053] Main material: Q235 steel

[0054] 3 induced draft fan

[0055] Form: centrifugal fan

[0056] Air volume: 100000m 3 / h

[0057] Wind pressure: 3000Pa

[0058] Speed: 960r / min

[0059] Equipped with variable frequency motor power: 220kW, rated voltage: 380V

[0060] Covered area: about 300m 2 .

[0061] 4 wet absorption tower 3

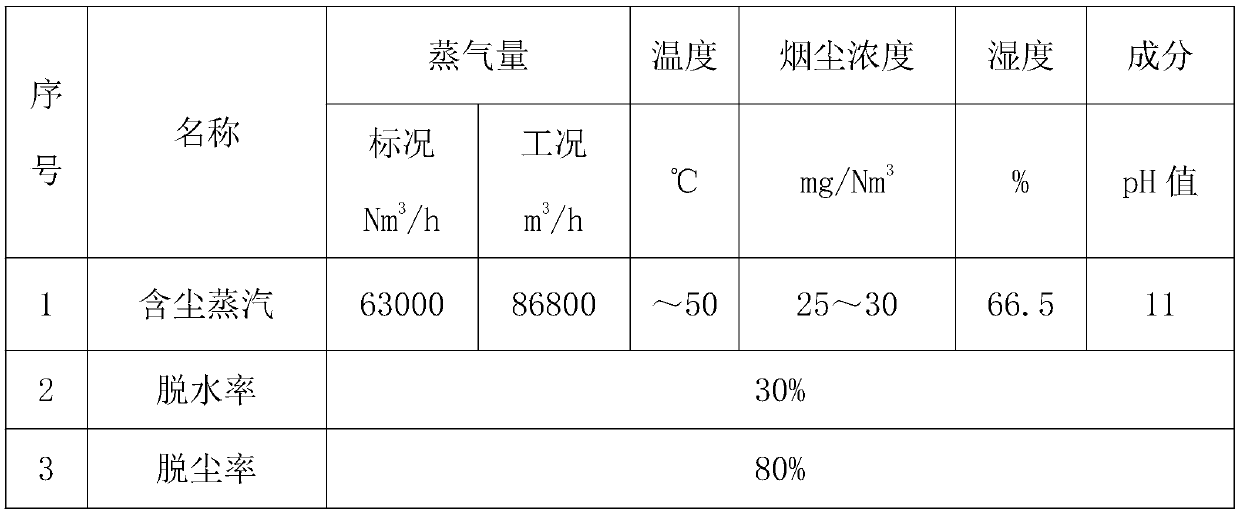

[0062] Table 1 Parameters of outlet flue gas treated by spray tower + dehydrator

[0063]

[0064] Table 2 Flue gas parameters after treatment by spray tower + dehydrator + wet absorption tower

[0065]

[0066] After the test, as shown in Table 2, the dust content of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap