Concrete compacting machine

A compactor and concrete technology, applied in the field of mechanical equipment, can solve the problems of large force and falling of loose stones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

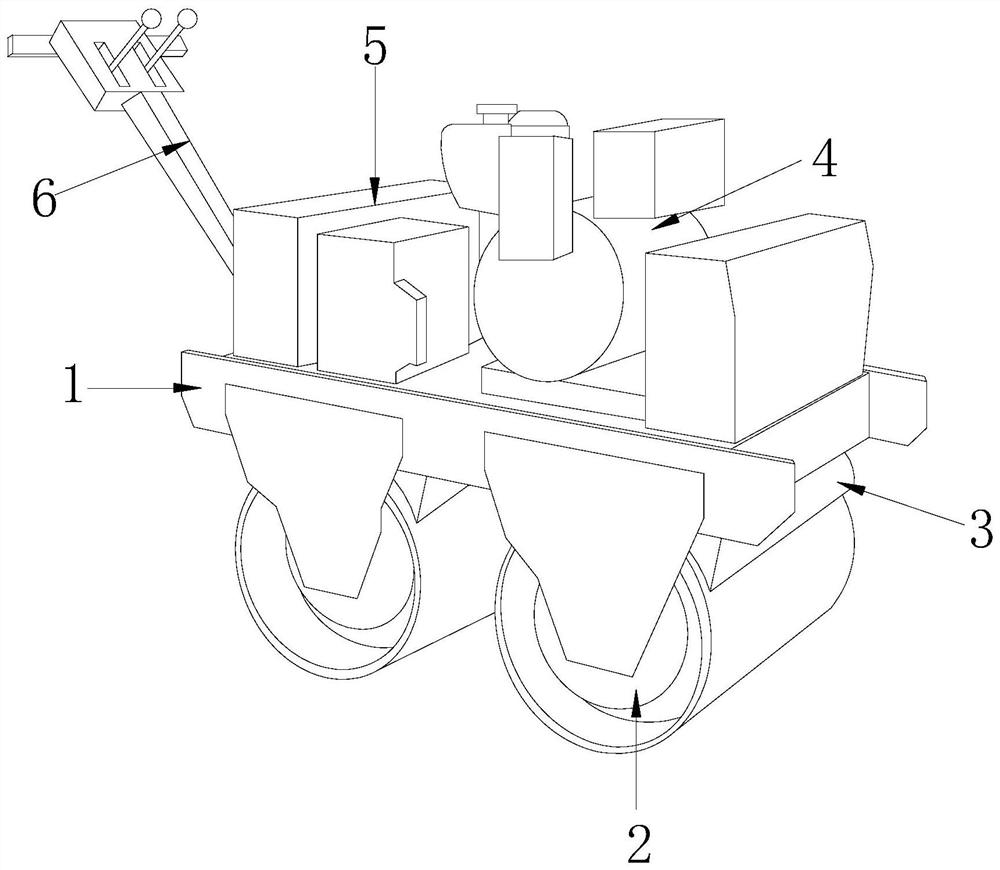

[0029] Such as Figure 1-Figure 5 As shown, the invention provides a kind of technical scheme of concrete compactor:

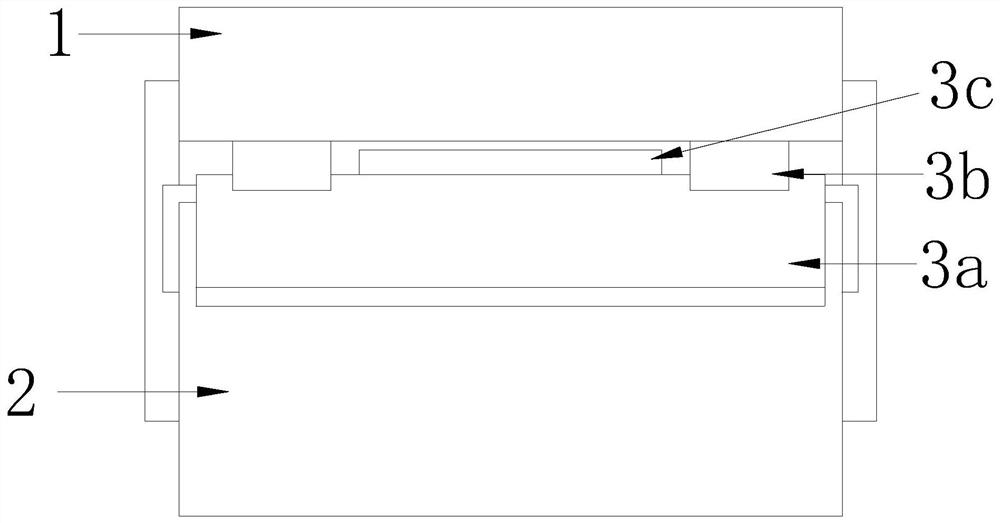

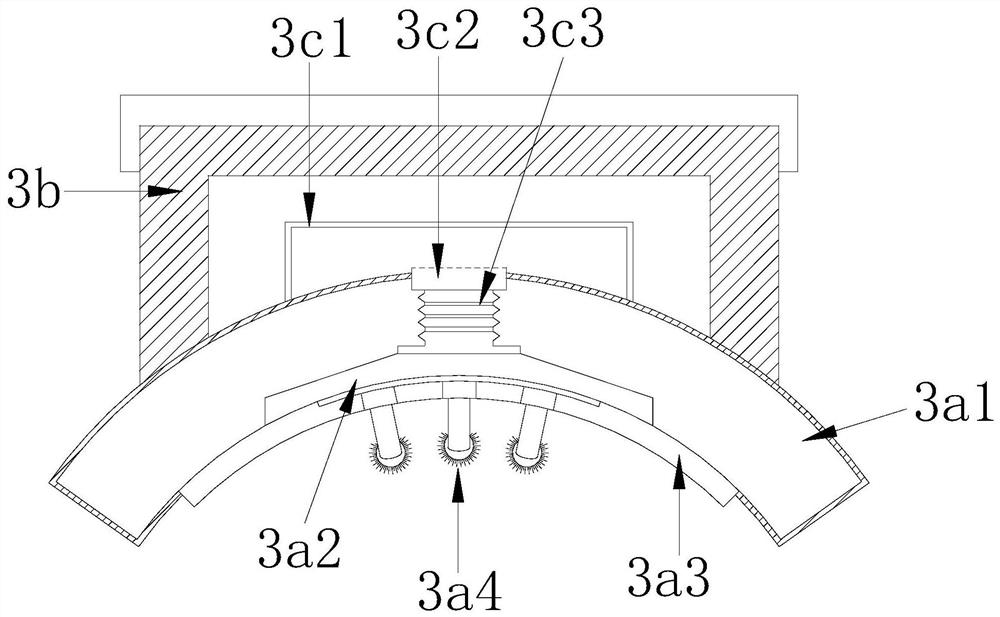

[0030] Such as Figure 1-Figure 2 Shown, a kind of concrete compactor, its structure comprises machine main body 1, compaction shaft 2, straightening device 3, drive motor 4, transmission case 5, pusher 6, and described compaction shaft 2 is provided with two and They are respectively installed on the lower surface of the main body 1. There are two straightening devices 3 which are respectively installed above the compaction shaft 2 and connected to the lower surface of the main body 1. The driving motor 4 is arranged on the main body 1 On the upper surface, the transmission box 5 is electrically connected to the drive motor 4, the push handle 6 is installed on the rear surface of the main body 1 and welded together, and the smoothing device 3 includes a pushing mechanism 3a, a mounting buckle 3b, and a crushing structure 3c , the installation buckle 3b is a...

no. 2 example

[0040] Such as figure 2 , Image 6 As shown, the invention provides a kind of technical scheme of concrete compactor:

[0041] Such as figure 2 As shown, a concrete compactor, the structure of which includes the nanostructure 3c including a frame 3c1, a single intake valve 3c2, and a connecting pipe 3c3, the single intake valve 3c2 is arranged on the lower surface of the frame 3c1 and is Integrated structure, the connecting pipe 3c3 is arranged on the lower surface of the single air inlet valve 3c2 and connected through it, and the other end of the connecting pipe 3c3 is connected through the perfusion sleeve 3a2, which is beneficial to realize the absorption of stray concrete particles, Therefore, it is avoided that the traditional compactor falls to the compacted concrete surface after the concrete impurities attached to the surface of the compaction shaft are removed.

[0042] Such as Image 6 As shown, the inside of the frame 3c1 is provided with an adsorption airflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com