Pipeline support assembly type pile foundation structure

A pipeline support and assembled technology, applied in the field of pile foundation structure, can solve problems such as pipeline deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

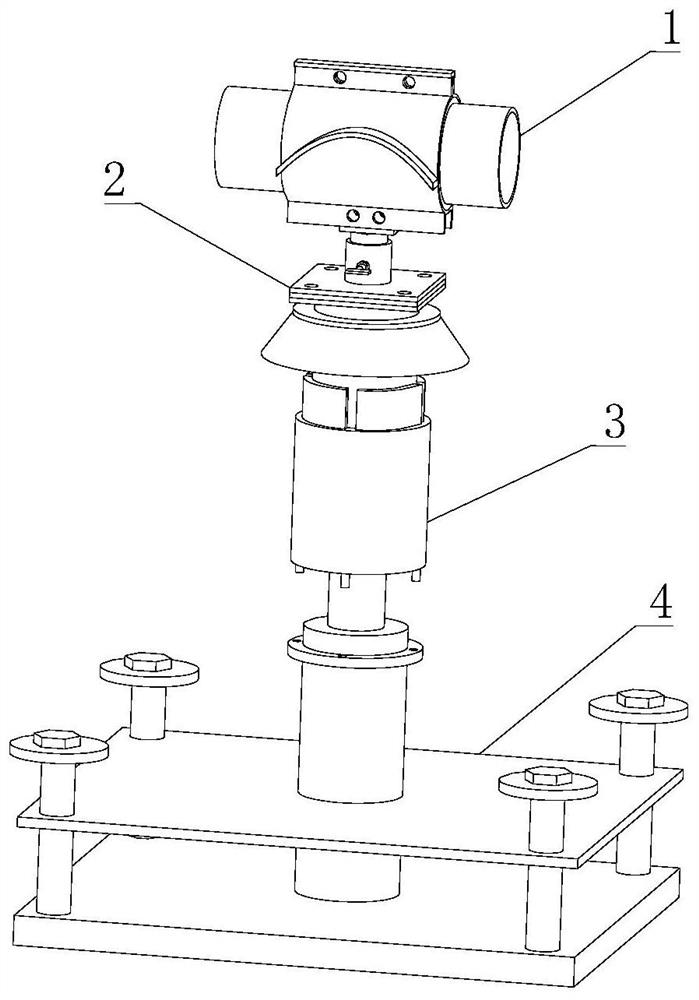

[0034] Such as Figure 1-7 As shown, the present invention provides a pipeline support assembly type pile foundation structure, including a pipeline 1, a pipeline installation device 2 is fixedly connected to the outside of the pipeline 1, an assembly support 3 is fixedly installed under the pipeline installation device 2, and the assembly support 3 is fixedly connected to the bottom of the pipeline. With base 4.

[0035] In this embodiment, the pipeline installation device 2 is responsible for fixing the pipeline 1 and changing the installation direction of the bracket, the assembly pillar 3 is used for supporting the whole bracket, and the base 4 is used for fixing the bracket underground.

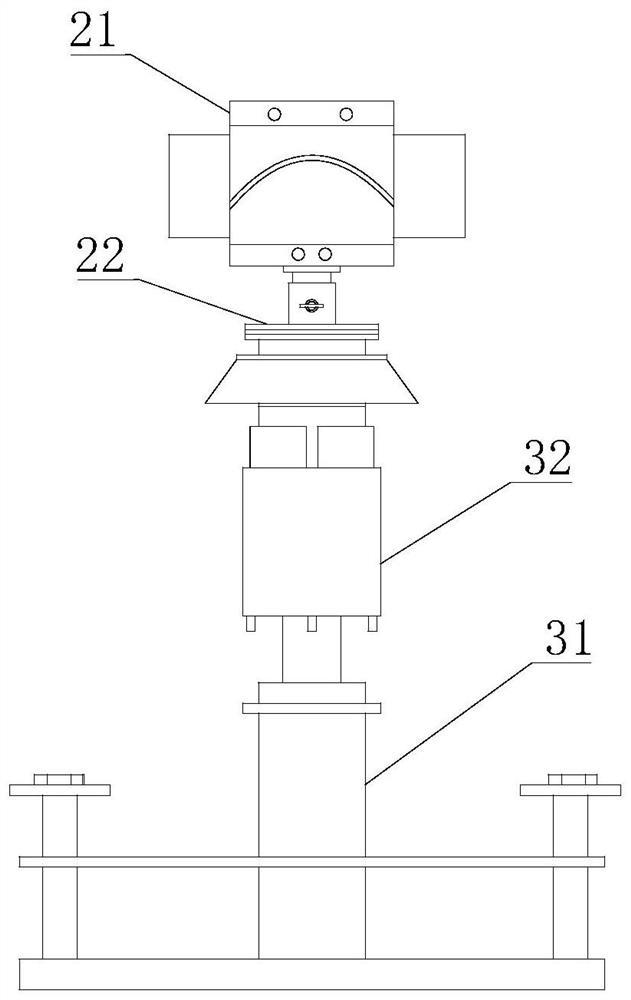

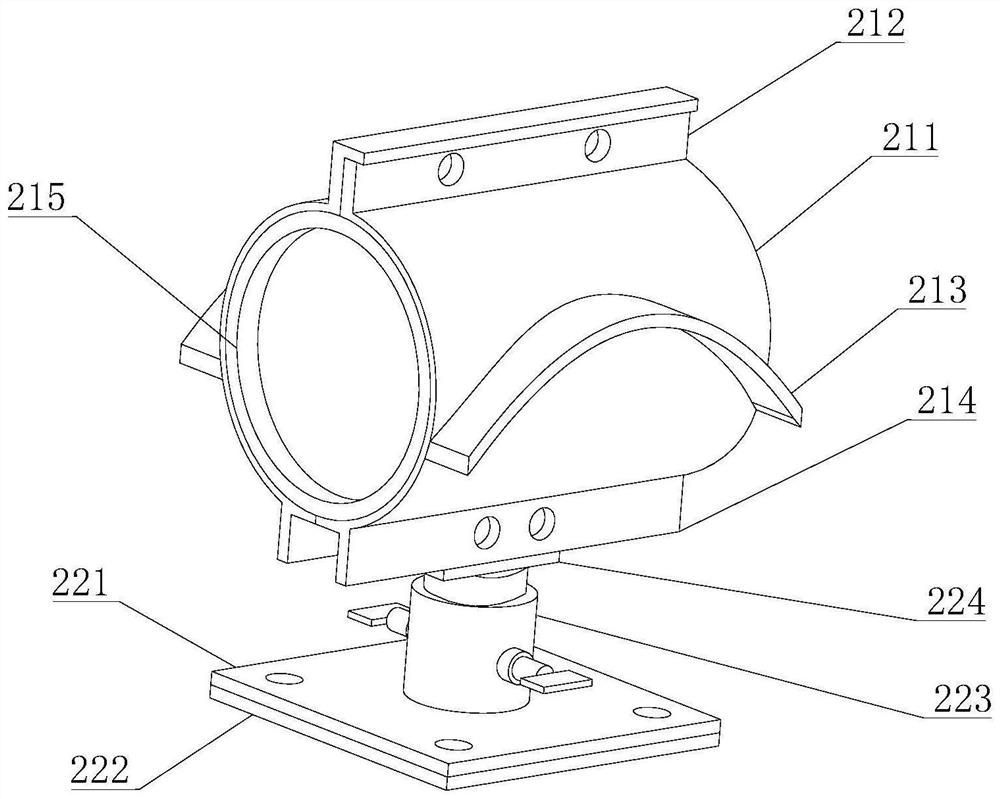

[0036] Such as Figure 1-7 As shown, in this embodiment, preferably, the pipeline installation device 2 includes a pipeline fixing device 21, a pipeline support device 22 is fixedly installed under the pipeline fixing device 21, and the pipeline fixing device 21 includes a fixing collar...

Embodiment 2

[0038] Such as Figure 1-7As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the pipeline support device 22 includes a connecting block 224, and the connecting block 224 is fixedly connected between the lower fixing plates 214 by bolts, and the connecting block 224 The lower part is fixedly equipped with a rotating supporting device 223, the lower surface of the rotating supporting device 223 is fixedly connected with an upper supporting plate 221, and an elastic sealing washer 222 is arranged below the upper supporting plate 221, and the rotating supporting device 223 includes a rotating shaft 2231, which is fixedly connected On the lower surface of the connecting block 224, the outer periphery of the rotating shaft 2231 is movably sleeved with a rotating collar 2232, and the lower part of the rotating collar 2232 is fixedly connected to the upper surface of the upper support plate 221. The front and rear surfaces of the ro...

Embodiment 3

[0040] Such as Figure 1-7 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the assembly pillar 3 includes a lower pillar 31, and the upper pillar 32 is threaded inside the lower pillar 31, and the lower pillar 31 includes a pillar Sleeve 311, the upper end of the pillar sleeve 311 is fixed with a limit ring 312, the surface of the limit ring 312 is provided with a limit hole 313, the upper pillar 32 includes a threaded rod 321, and the lower end of the threaded rod 321 is threaded on the pillar sleeve 311 The inner upper end, the upper end of the threaded rod 321 is fixedly connected with a support column 322, the upper surface of the support column 322 is fixedly equipped with a lower support plate 325, the outer upper end of the support column 322 is fixedly installed with a waterproof cover 324, and the outer surface of the support column 322 is provided with a positioning groove. The support column 322 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com