Method for cleaning silt in water inlet pool on front side of water delivery pump station

A cleaning method and technology for water inlet pools, applied in pumping stations, chemical instruments and methods, water supply devices, etc., can solve water pump impeller wear, water quality pollution in pumping stations, and provisions for cleaning sediment in water inlet pools for pumping stations without water delivery, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

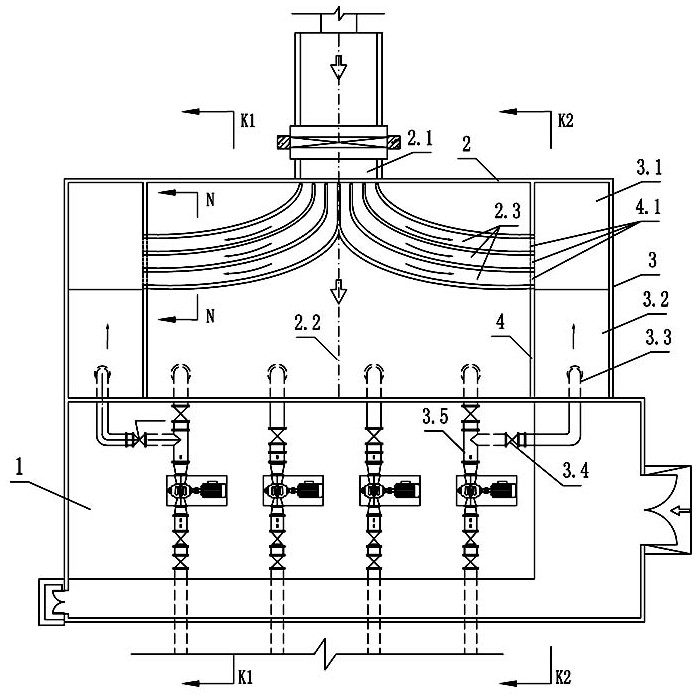

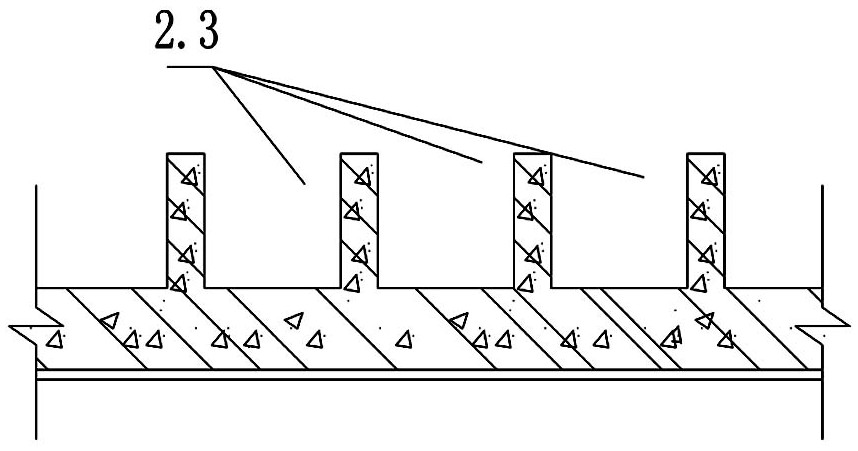

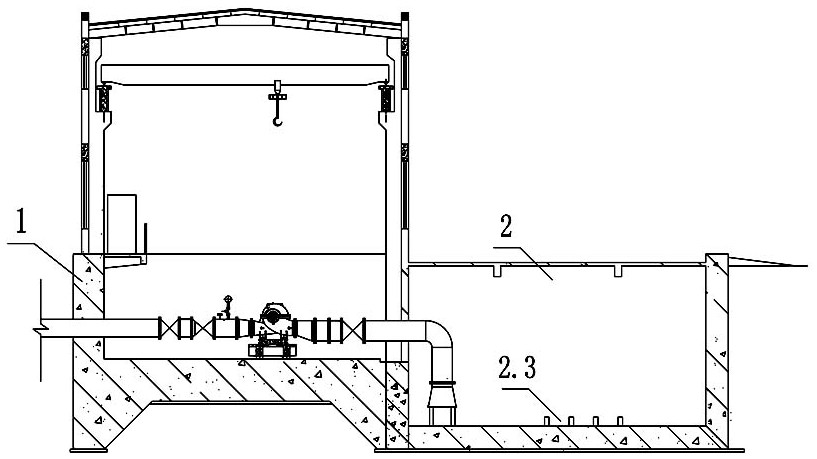

[0029] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

[0030] like Figure 1-4 As shown, the method for cleaning the sediment in the front inlet pool of the water pumping station of the present invention comprises the following steps:

[0031] S1, during the construction period of the water pumping station 1, the water inlet pool 2 is built at the same time, the water inlet 2.1 of the water inlet pool 2 is facing the water pumping station 1, and a water inlet 2.2 is symmetrically arranged on both sides of the water inlet pool 2. The sedimentation ponds 3 with the same structure, two sedimentation ponds 3 are separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com