Water collector blade based on separation membrane, water collector and cooling tower

A separation membrane and water collector technology, applied in the fields of water collector blades, water collectors, and cooling towers, can solve problems such as long time consumption, difficulty in ensuring water vapor recovery rate and recovery efficiency, and reduced water collection capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

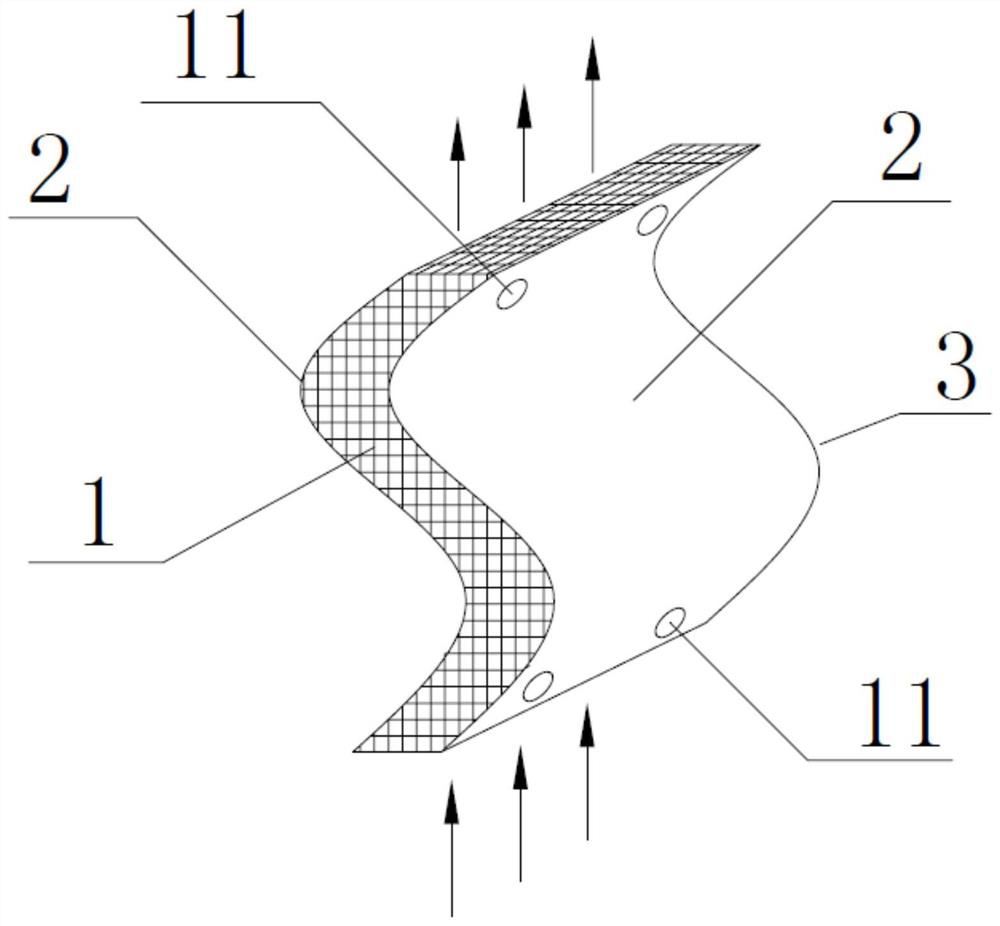

[0040] Such as figure 1 Shown is an embodiment of a water eliminator blade based on a separation membrane of the present invention, which includes a hydrophilic device 1 that collects droplets entrained in the air flow when the air flow passes through it using a hydrophilic component. A separation membrane 2 with hydrophilic and hydrophobic functions, the side of the separation membrane 2 with the hydrophilic function is attached to the hydrophilic device 1, and the side of the separation membrane 2 with the hydrophobic function is away from the hydrophilic device 1, and the droplets can pass through the separation The membrane 2 enters the hydrophilic device 1 .

[0041] As an embodiment of the present invention, the separation membrane 2 is a Janus membrane, and the Janus membrane includes a first membrane with a hydrophilic function and a second membrane with a hydrophobic function, and the first membrane and the second membrane are closely attached.

[0042] The hydrophil...

Embodiment 2

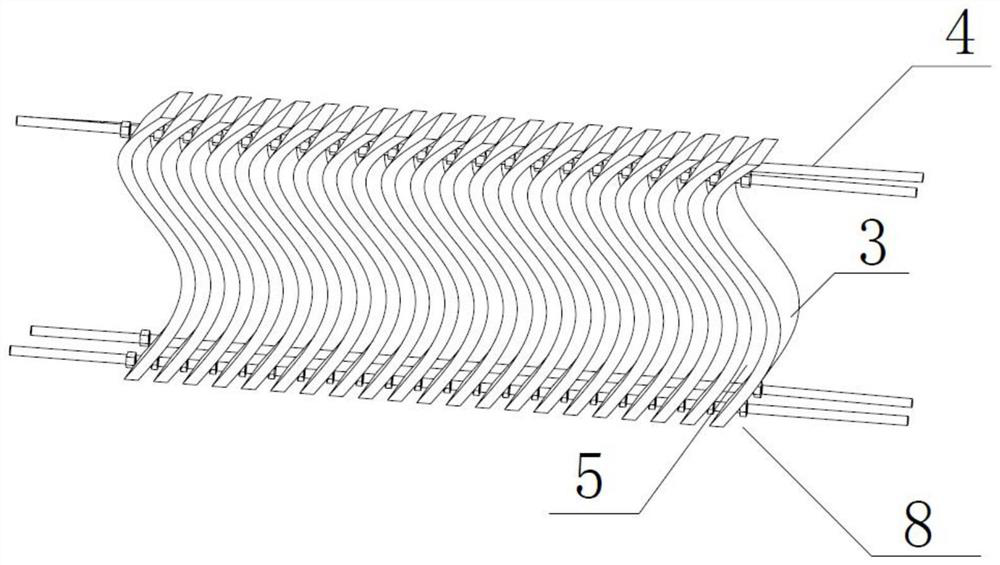

[0054] Such as figure 2 Shown is an embodiment of a cooling tower water eliminator based on a separation membrane of the present invention, including several water eliminator blades 3 based on a separation membrane 2 as described above, used to connect several water eliminator blades 3 and used to make the water eliminator The water receiver 8 can be fixed on the fixing device 4 in the cooling tower. A plurality of water eliminator blades 3 are sequentially staggered and partially overlapped on the fixing device 4. The water eliminator blades 3 are connected with the fixing device 4, and the adjacent water collectors Separation membrane channels 5 are formed between the vanes 3 of the device.

[0055] The fixing device 4 is used for arranging and connecting a plurality of water eliminator blades 3 based on the separation membrane 2 in order to form a water eliminator 8 composed of several water eliminator blades 3 . The collection of liquid droplets in the hot and humid air ...

Embodiment 3

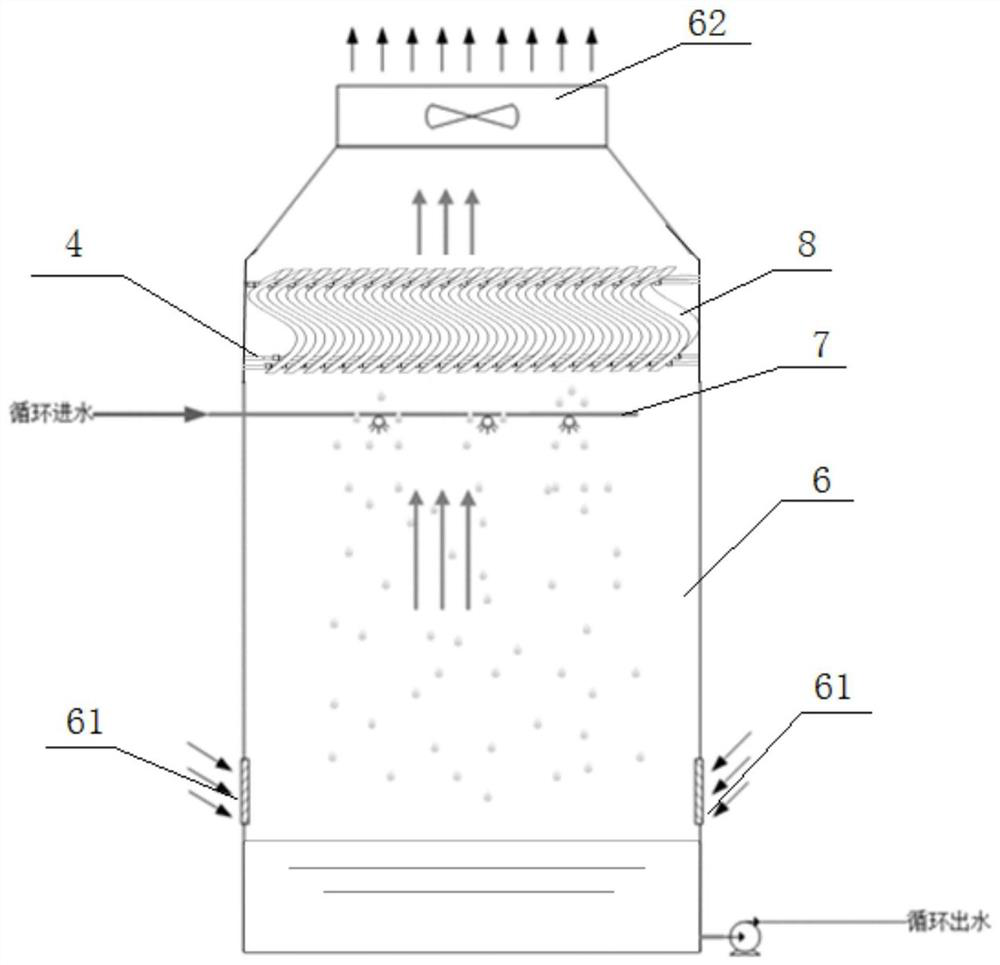

[0063] Such as image 3 Shown is an embodiment of a cooling tower based on a separation film of the present invention, including a cooling tower body 6, an air inlet 61 and an air outlet 62 are arranged on the cooling tower body 6, and the air inlet 61 is arranged at the lower part of the cooling tower body 6 , the air outlet 62 is arranged on the top of the cooling tower body 6, and the spray device 7 is arranged in the cooling tower body 6, and the cooling tower water eliminator 8 based on the separation film as above is arranged between the air outlet 62 and the spray device 7 ; The air flow enters the cooling tower body 6 from the air inlet 61 and then flows through the spray device 7 and the water collector 8 and then flows out from the air outlet 62 .

[0064] The cooling tower body 6 provides a cooling place; the spray device 7 realizes the filtering and cooling functions, but it will cause a lot of water to be mixed in the waste gas; the cooling tower water eliminator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com