Shellfish harvester

A technology for harvesting and shellfish, applied in the field of seafood harvesting devices, can solve problems such as affecting the economic benefits of farmers, time-consuming and laborious, and affecting the ecological environment of the sea area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

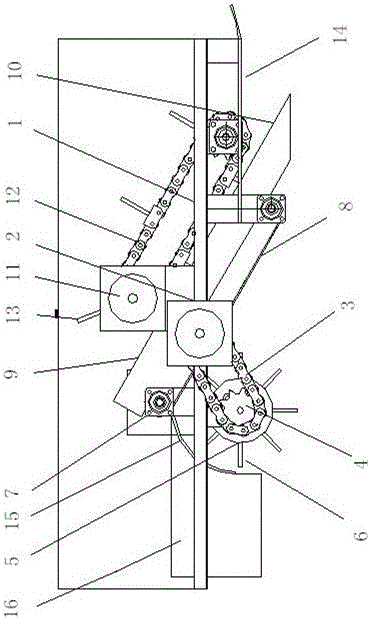

[0012] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: a shellfish harvesting machine, including a base frame 1, on which two travel motors 2 are symmetrically arranged, and each travel motor 2 is connected with a travel gear 4 through a travel chain 3 , while the rotating shaft of the travel gear 4 is rotatably supported on the frame 1, and the travel gear 4 and the travel wheel 5 are connected to each other, and a plurality of travel wheel plates evenly distributed on the circumference are arranged outside the shaft wheel 5 6. A conveyor belt motor 7 is also provided on the frame 1. The working end of the conveyor belt motor 7 is connected to the active transmission shaft rotatably supported on the frame 1, and the bottom of the frame 1 is also rotatably supported with a passive transmission shaft. A conveyor belt 8 is jointly supported on the active transmission shaft a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com