High-precision rapid graph detection and identification method

A technology of image detection and recognition methods, applied in image enhancement, image analysis, image data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

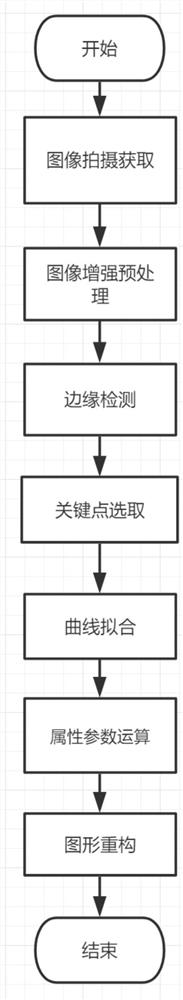

[0137] combine figure 1 , The high-precision and fast pattern detection and recognition method is divided into seven steps: image capture, image enhancement preprocessing, edge detection, key point selection, curve fitting, attribute parameter calculation, and pattern reconstruction.

[0138] 1. The camera uses an industrial CCD camera. Compared with a CMOS camera, a CCD camera can obtain images with less noise and higher image quality.

[0139] Fix the camera to the specified position on the workbench, perform camera calibration, obtain data such as the distortion parameters of the camera and the external rotation matrix, calculate the parameter matrix of the camera, and then shoot the workpiece to obtain a uniform 1024×768 pixel image of the workpiece, such as Figure 5 .

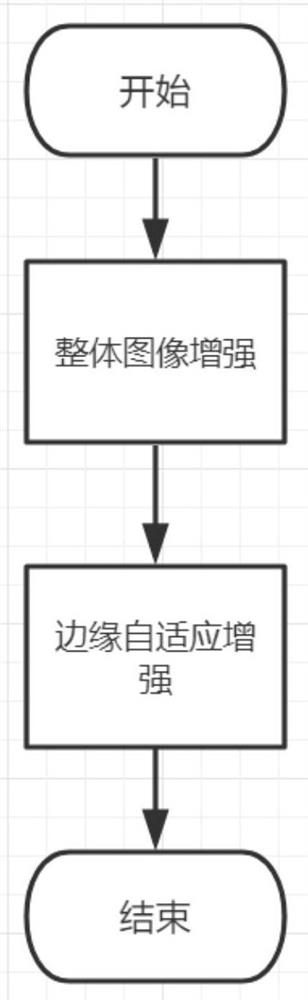

[0140] 2. Image enhancement preprocessing

[0141] During the image acquisition process, due to the light source, shooting angle, etc., the obtained image may have insufficient brightness and unclear ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com