A kind of microporous layer slurry, gas diffusion layer, fuel cell and preparation method

A technology of gas diffusion layer and microporous layer, which is applied in the direction of fuel cells, battery electrodes, circuits, etc., and can solve the problems of reduced product life and inability to transmit gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

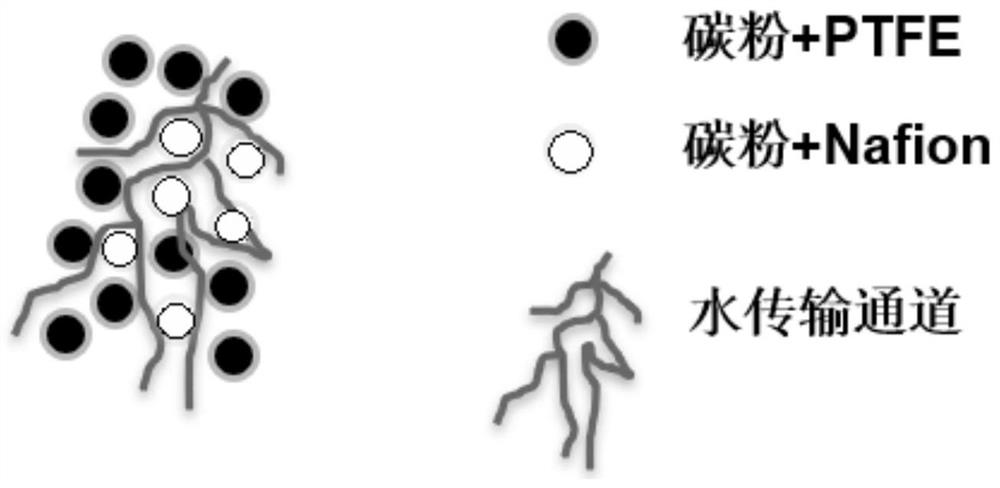

Image

Examples

preparation example Construction

[0040] The embodiment of the present application also provides a method for preparing the above-mentioned microporous layer slurry, which includes the following steps:

[0041] (1) Proportionally disperse the hydrophobic agent, perfluorosulfonic acid polymer or its corresponding salt in a solvent formed by water and organic solvent to obtain a gel.

[0042] (2) Adding the carbon-based material into the gel, stirring, ball milling, and dispersing to obtain a microporous layer slurry. Usually, the stirring rate is 2000-3000rad / min, and the stirring time is 1-3h; the ball milling rate is 100-500rad / min, and the ball-milling time is 2-5h; the dispersion time is 1-3h, so as to ensure that the carbon-based material particles are uniform and uniform in the gel.

[0043] The embodiment of the present application also provides a method for preparing a gas diffusion layer, which includes the following steps:

[0044] 1. Hydrophobic treatment of the base layer (GB) for subsequent use. ...

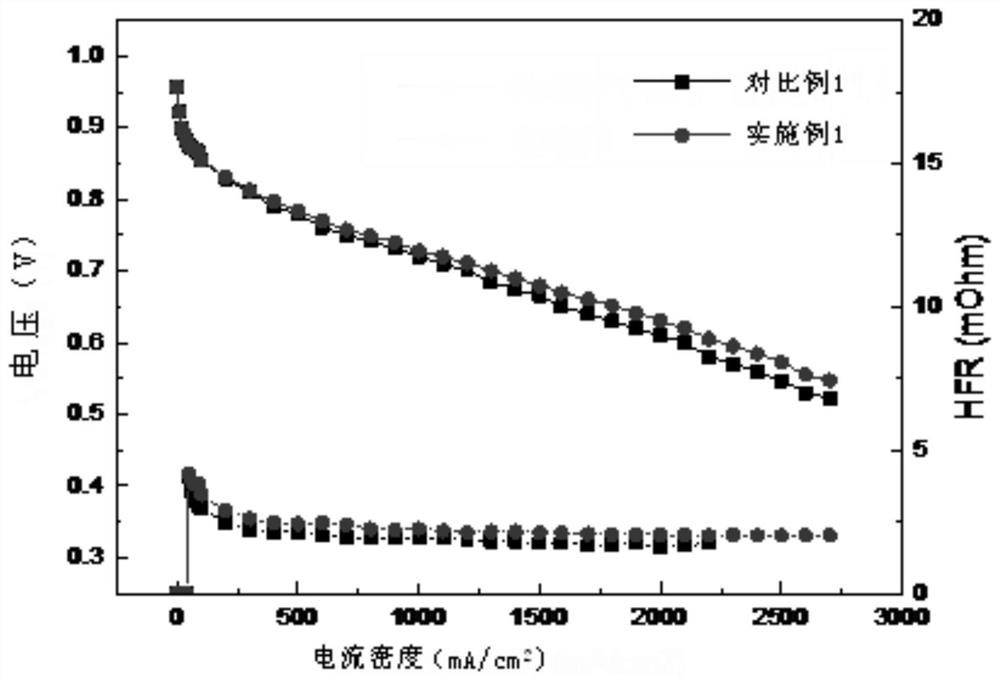

Embodiment 1

[0054] This embodiment provides a gas diffusion layer and a fuel cell, which can be prepared according to the following preparation methods:

[0055] (1) The carbon paper is hydrophobized with the hydrophobic agent PTFE. The specific method is to place the carbon paper in the PTFE aqueous dispersion and soak it. The amount of PTFE is 10% of the mass of the carbon paper. It is heated to 100 ° C and treated for 10 minutes to obtain Hydrophobized carbon paper, as GB.

[0056] (2) Add carbon powder, PTFE powder and sulfonic acid resin salt to the hydroalcoholic solution (water: ethanol = 7:3), specifically, first add PTFE powder and sulfonic acid resin salt to the hydroalcoholic solution and ultrasonically disperse to obtain a gel Then add carbon powder to the gel, the mass ratio of carbon powder and water-alcohol solution is 1:9, the mass of PTFE powder is 25% of the mass of carbon powder, and the sulfonic acid resin salt is 5% of the mass of carbon powder , followed by stirring...

Embodiment 2

[0061] This embodiment provides a gas diffusion layer and a fuel cell, which can be prepared according to the following preparation methods:

[0062] (1) The carbon paper is subjected to hydrophobization treatment with a hydrophobizing agent PTFE, and the process is the same as in Example 1 to obtain a hydrophobization carbon paper.

[0063] (2) Add carbon powder, PTFE powder and sulfonic acid resin salt to the hydroalcoholic solution (water:ethanol=7:3), the mass ratio of carbon powder and hydroalcoholic solution is 1:5, and the mass of PTFE powder is carbon 20% of the powder mass, sulfonic acid resin salt is 10% of the carbon powder mass, then stirred at 2500rad / min for 1.5h, ball milled at 300rad / min for 3h, and ultrasonically dispersed for 60 minutes to obtain a microporous layer slurry.

[0064] (3) Coating the microporous layer slurry treated in step (2) on the hydrophobized carbon paper in (1), the treatment process is the same as in Example 1 to obtain a gas diffusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com