Rotor punching sheet of permanent magnet synchronous motor

A permanent magnet synchronous motor and rotor punching technology, which is applied to synchronous machine parts, magnetic circuits, electrical components, etc., can solve the problems of heavy rotor punching structure, inconvenient clamping, and bulky structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

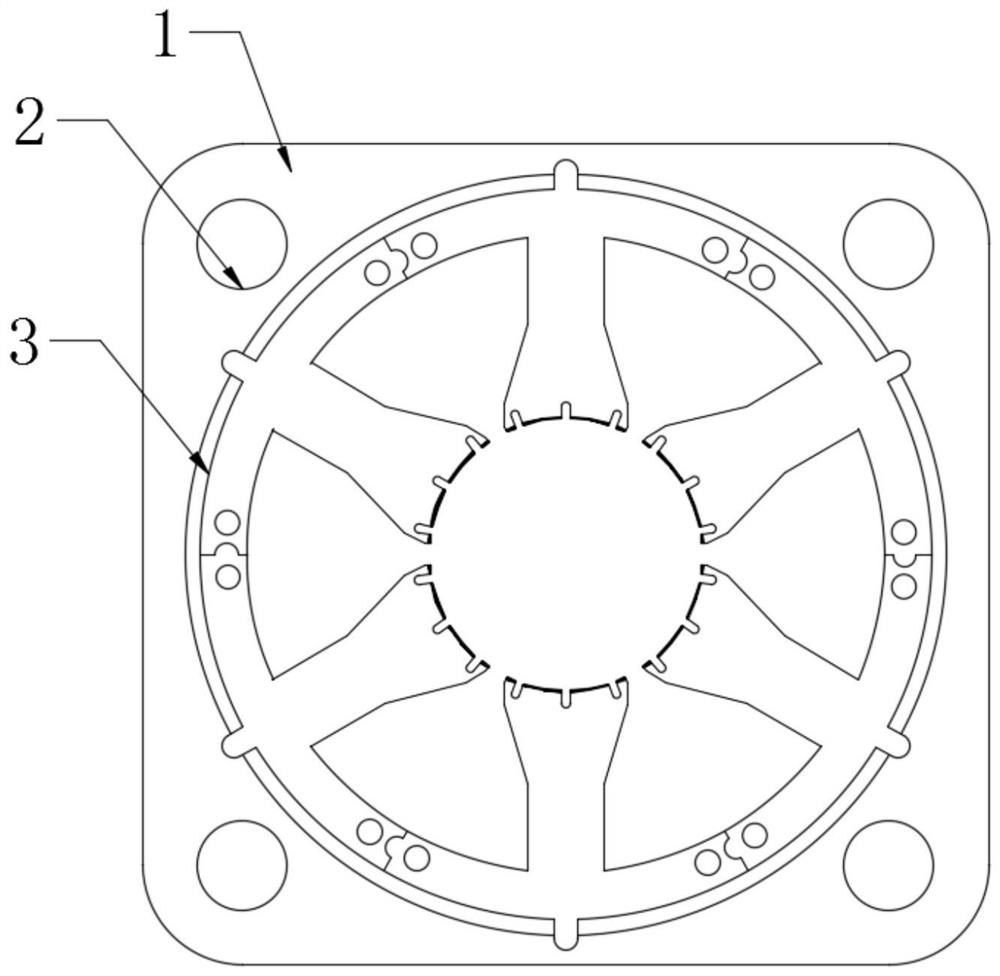

[0021] see Figure 1-Figure 4 , the present invention provides a technical solution: the rotor punching of the permanent magnet synchronous motor includes a punching main body 1, a pin hole 2 and a lightweight and easy-to-fit mechanism 3, the punching main body 1 is provided with a pin hole 2, and the punching body 1 There is a light-weight and easy-to-install mechanism 3 inside.

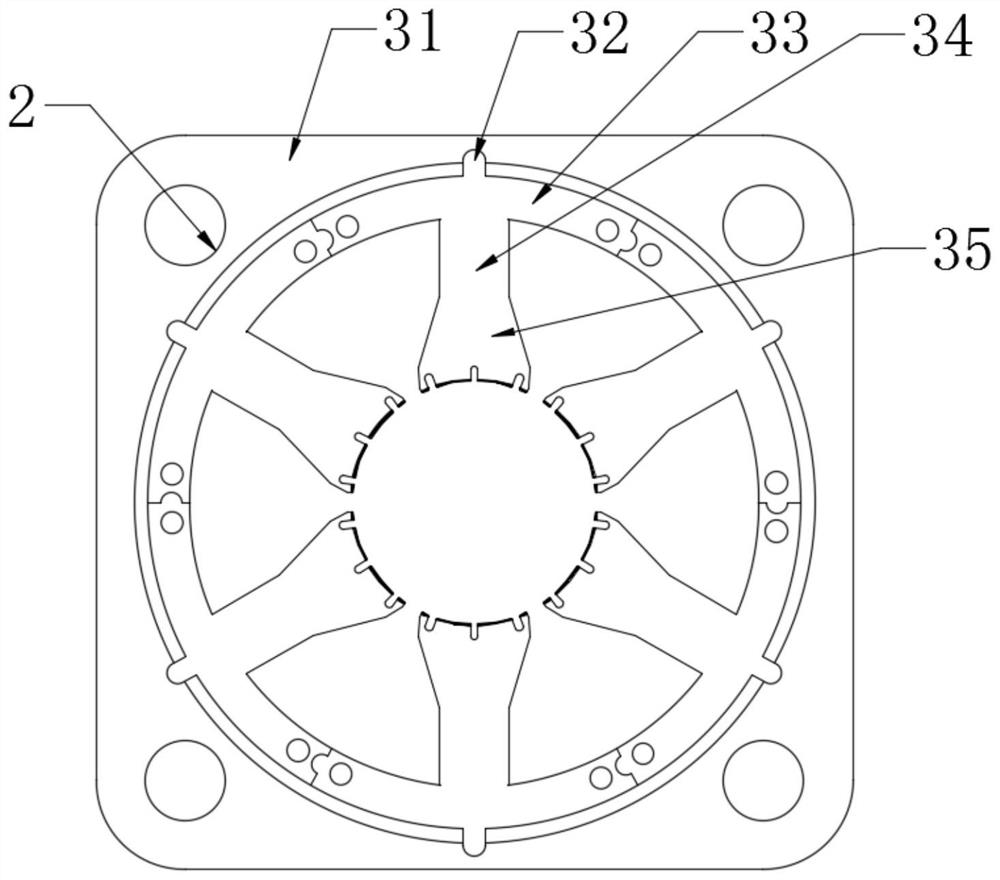

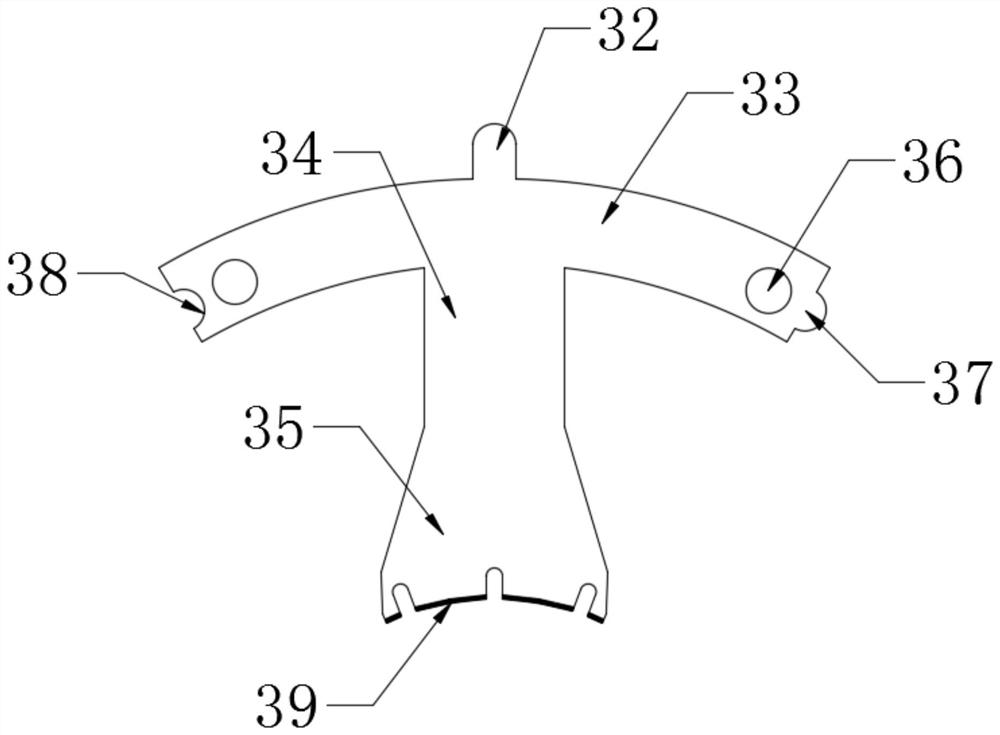

[0022] Lightweight and easy to install. The mechanism 3 includes a stator yoke 31, a first chuck 32, a splicing rod 33, a connecting rod 34, a pole piece 35, a positioning bump 36, a second chuck 37, a groove 38 and a lubricating film 39. A stator yoke 31 is installed on the outer side of the main body 1 of the punching sheet, and a pole shoe 35 is installed on the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com