Liquid crystal composition and application thereof

A technology for liquid crystal compositions and compounds, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of poor mutual solubility, low temperature stability of liquid crystal materials, and small temperature dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

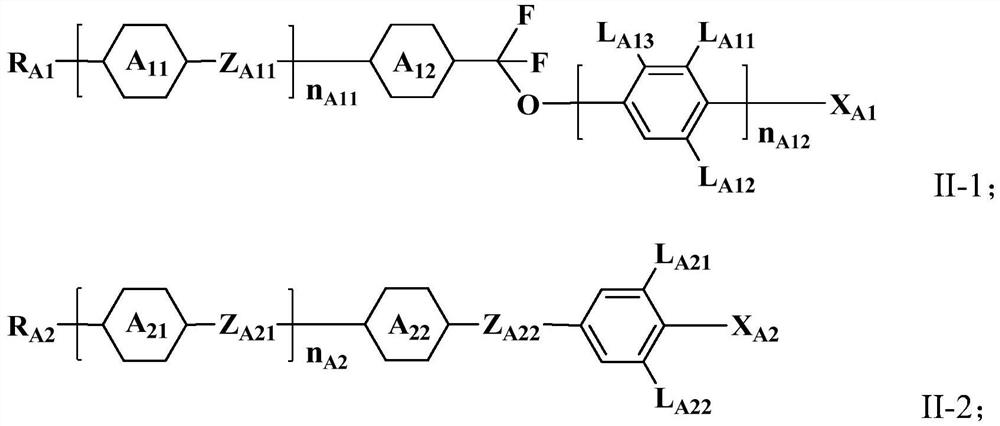

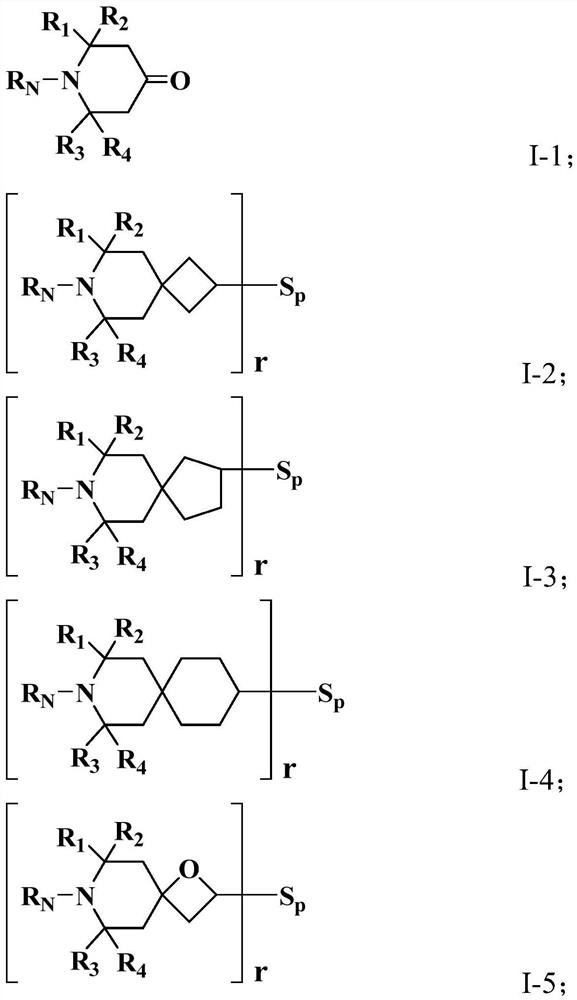

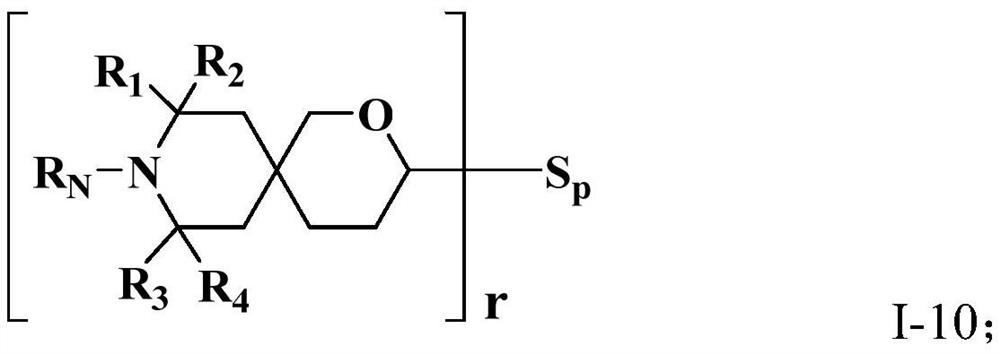

Method used

Image

Examples

Embodiment 1~15 and comparative example 1~4

[0112] A liquid crystal composition, comprising host Host-1 and a compound of formula I; the liquid crystal composition is obtained by mixing the components.

[0113] The composition and performance test results of the host Host-1 are shown in Table 2:

[0114] Table 2

[0115]

[0116]

[0117] By adding different contents of Compound A in Table 3 below to Host-1 (structure Belong to general formula I-1), compound B (structure is Belong to general formula I-1), compound C (structure is Belong to general formula I-4), compound D (structure is Belong to general formula I-6), compound E (structure is Belonging to the general formula I-4) and the comparative compound UV770 constitute Examples 1-15 and Comparative Examples 1-4 of the present invention, and their performance test results are shown in Table 3.

[0118] table 3

[0119]

[0120]

[0121] From the data in Table 3, it can be seen that the liquid crystal composition containing the compound of form...

Embodiment 16~30 and comparative example 5~8

[0123] A liquid crystal composition, comprising host Host-2 and a compound of formula I; the liquid crystal composition is obtained by mixing the components of the compound.

[0124] The composition and performance test results of the host Host-2 are shown in Table 4:

[0125] Table 4

[0126]

[0127] By adding different contents of Compound A, Compound B, Compound C, Compound D, Compound E and comparative compound UV770 in Table 5 below to Host-2, Examples 16-30 and Comparative Examples 5-8 of the present invention are formed. Its performance test results are shown in Table 5.

[0128] table 5

[0129]

[0130]

[0131] From the data in Table 5, it can be seen that the liquid crystal composition containing the compound of formula I of the present invention has better low temperature stability relative to the liquid crystal composition containing UV770, higher VHR-initial, VHR-UV and VHR-high temperature, lower Conductance I / V, the reliability of liquid crystal is...

Embodiment 31~45 and comparative example 9~12

[0133] A liquid crystal composition, comprising host Host-3 and a compound of formula I; the liquid crystal composition is obtained by mixing the components.

[0134] The composition and performance test results of the host Host-3 are shown in Table 6:

[0135] Table 6

[0136]

[0137]

[0138] By adding different contents of Compound A, Compound B, Compound C, Compound D, Compound E and comparative compound UV770 in Table 7 below to Host-3, Examples 31-45 and Comparative Examples 9-12 of the present invention were formed, Its performance test results are shown in Table 7.

[0139] Table 7

[0140]

[0141]

[0142] From the data in Table 7, it can be seen that the liquid crystal composition containing the compound of formula I of the present invention has better low-temperature stability relative to the liquid crystal composition containing UV770, higher VHR-initial, VHR-UV and VHR-high temperature, lower Conductance I / V, the reliability of liquid crystal is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com