Rotary classifying screen with adjustable amplitude and inclination angle

A grading sieve and amplitude technology, which is applied in the field of grading sieves, can solve problems such as the inability to adjust the amplitude and inclination of the grading sieve, and achieve the effect of changing the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

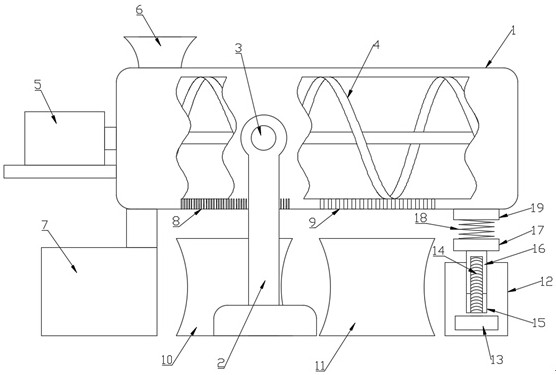

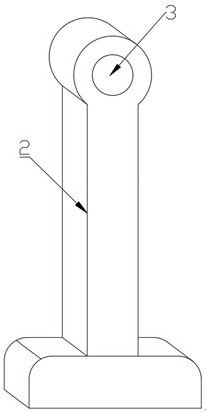

[0020] see figure 1 and figure 2 , the present invention provides a rotary grading screen with adjustable amplitude and inclination, including a screen cylinder 1, a support frame 2, and a vibrating device 7, and the screen cylinder 1 is installed between two support frames 2 through a rotating shaft 3 , the vibration device 7 is located below the screen cylinder 1, and the vibration device 7 is in contact with the head end of the screen cylinder 1, and the end of the screen cylinder 1 is connected with an amplitude tilt adjustment mechanism.

[0021] The amplitude and inclination adjustment mechanism includes a fixed block 12, a motor 13, a slider 16 and a support plate 19, the motor 13 is fixedly installed inside the fixed block 12, and the end of the output shaft of the motor 13 is fixedly connected with a screw 14. The slider 16 is slidably installed in the chute 15 opened with the fixed block 12, the lead screw 14 is inserted inside the slider 16 and connected with the ...

Embodiment 2

[0029] In order to make the service life of the damping spring 18 longer, this embodiment is further improved on the basis of Embodiment 1. The improvement is: the damping spring 18 is made of carbon steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com