Hydraulic machine with automatic induction safety protection device

A safety protection device and automatic sensing technology, applied in the hydraulic field, can solve the problems of easy displacement, hydraulic position dislocation of the workpiece, and reduced production quality of the workpiece, and achieve the effects of increasing friction, reducing position dislocation, and improving production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

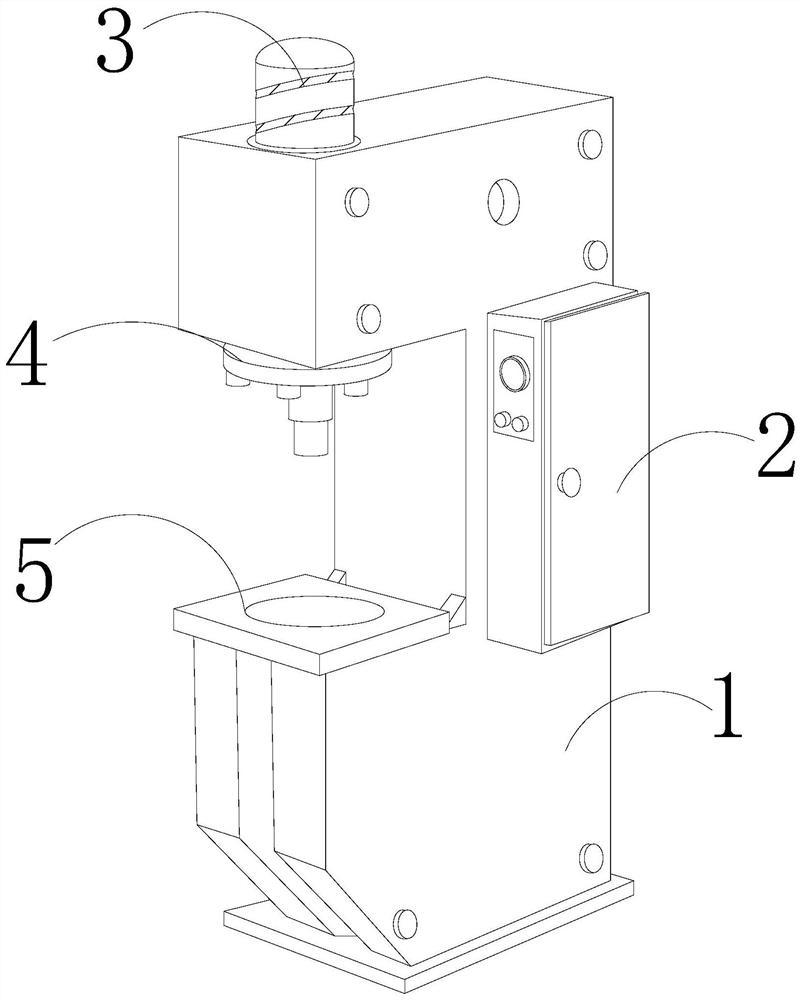

[0028] The present invention provides a hydraulic press with an automatic induction safety protection device, the structure of which includes a body 1, a controller 2, a hydraulic cylinder 3, a pressure rod 4, and a workbench 5. The controller 2 is arranged on the right side of the body 1, and the The hydraulic cylinder 3 is installed on the top of the body 1 , the pressure rod 4 is connected to the front bottom of the body 1 , and the workbench 5 is arranged below the pressure rod 4 .

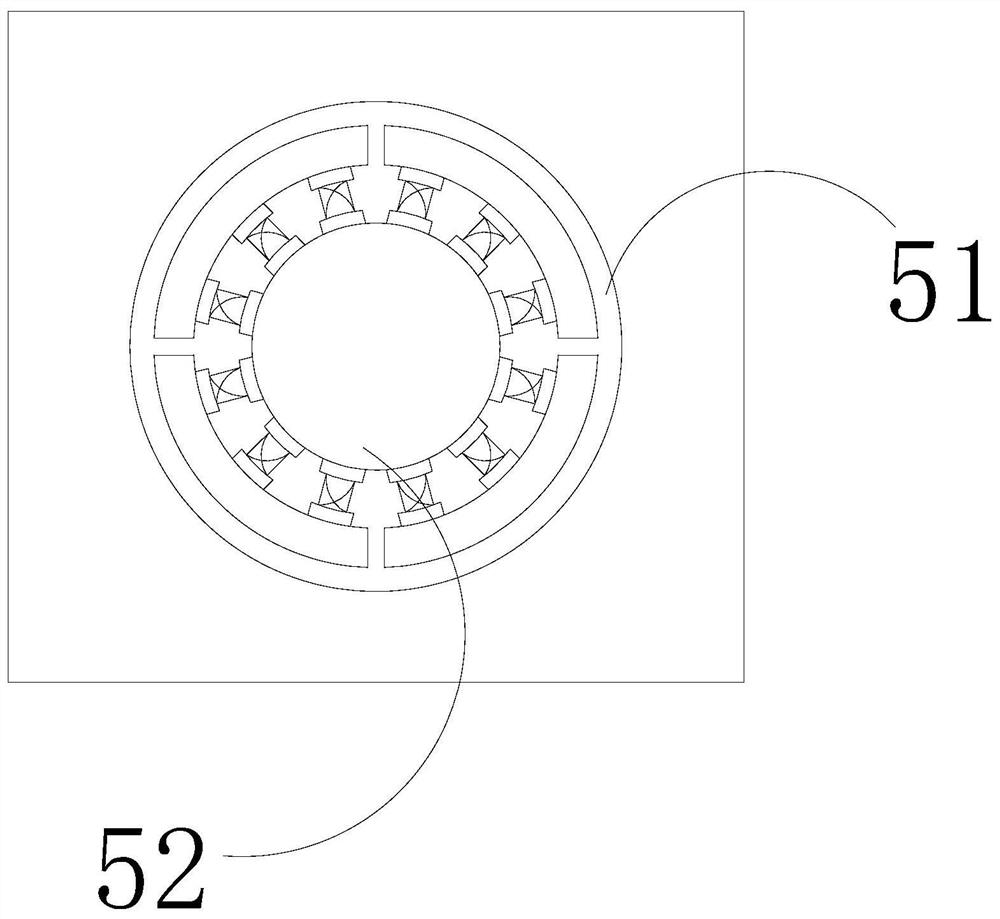

[0029] The workbench 5 is provided with a workpiece groove 51 and a clamping mechanism 52 , the workpiece groove 51 is recessed at the center of the top of the workbench 5 , and the clamping mechanism 52 is installed at the inner center of the workpiece groove 51 .

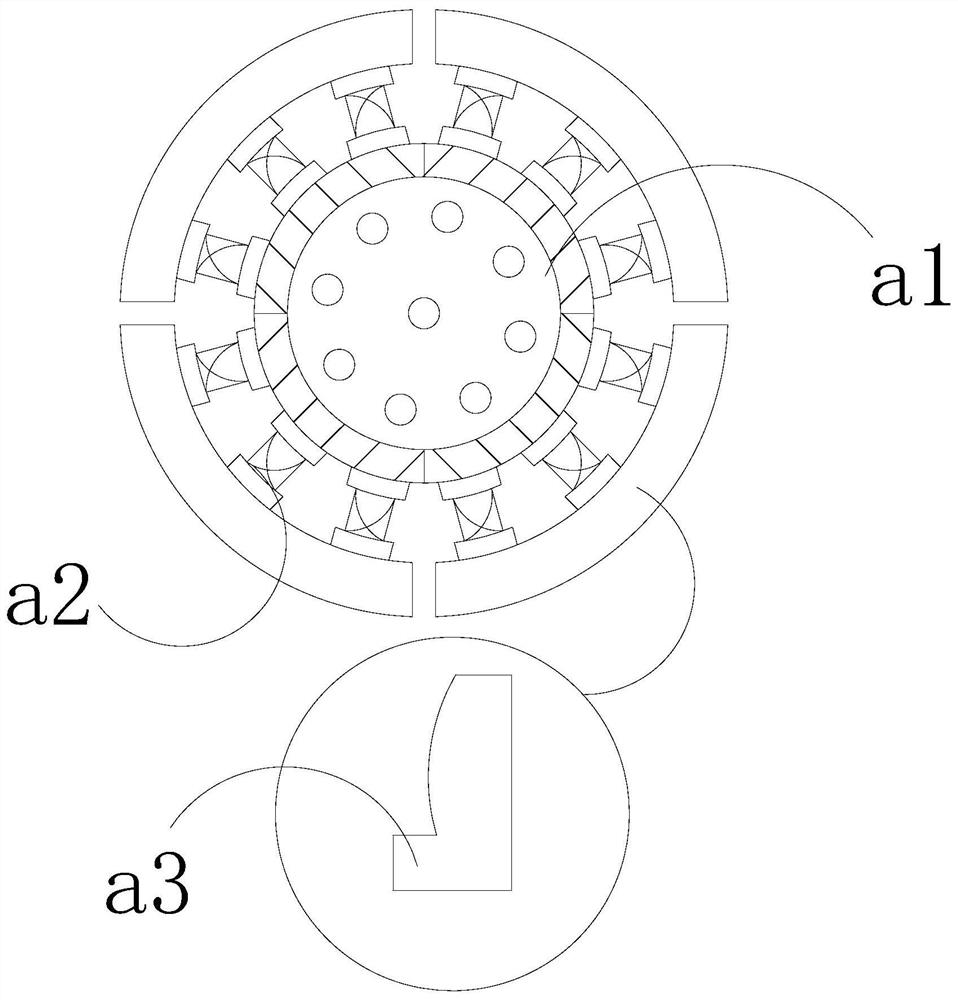

[0030] Wherein, the clamping mechanism 52 is provided with a support ring a1, a telescopic block a2, and a splint a3, the support ring a1 is located in the middle of the c...

Embodiment 2

[0036] as attached Figure 6 to attach Figure 8 Shown:

[0037] Wherein, the splint a3 is provided with a connection plate e1, a support plate e2, an inner groove e3, a push ball e4, an elastic block e5, and a contact plate e6, the connection plate e1 is located on the bottom surface of the splint a3, and the support plate e2 is connected and installed The top of the right end of the connecting plate e1, the inner groove e3 is set inside the supporting plate e2, the push ball e4 is set inside the inner groove e3, the contact plate e6 is connected to the left side of the supporting plate e2 through the elastic block e5, the There are nine push balls e4, which are evenly distributed inside the inner groove e3, which can increase the gravity of the support plate e2 and reduce the thrust swing of the support plate e2 by the workpiece. The inner groove e3 is inclined, which is conducive to pushing the ball e4 along Sliding along the inclined surface is beneficial for the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com