Radish slitting device for food

A radish and strip cutting technology, which is applied in metal processing and other directions, can solve the problem of not being able to cut large quantities at one time, and achieve the effect of saving manpower and facilitating collection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

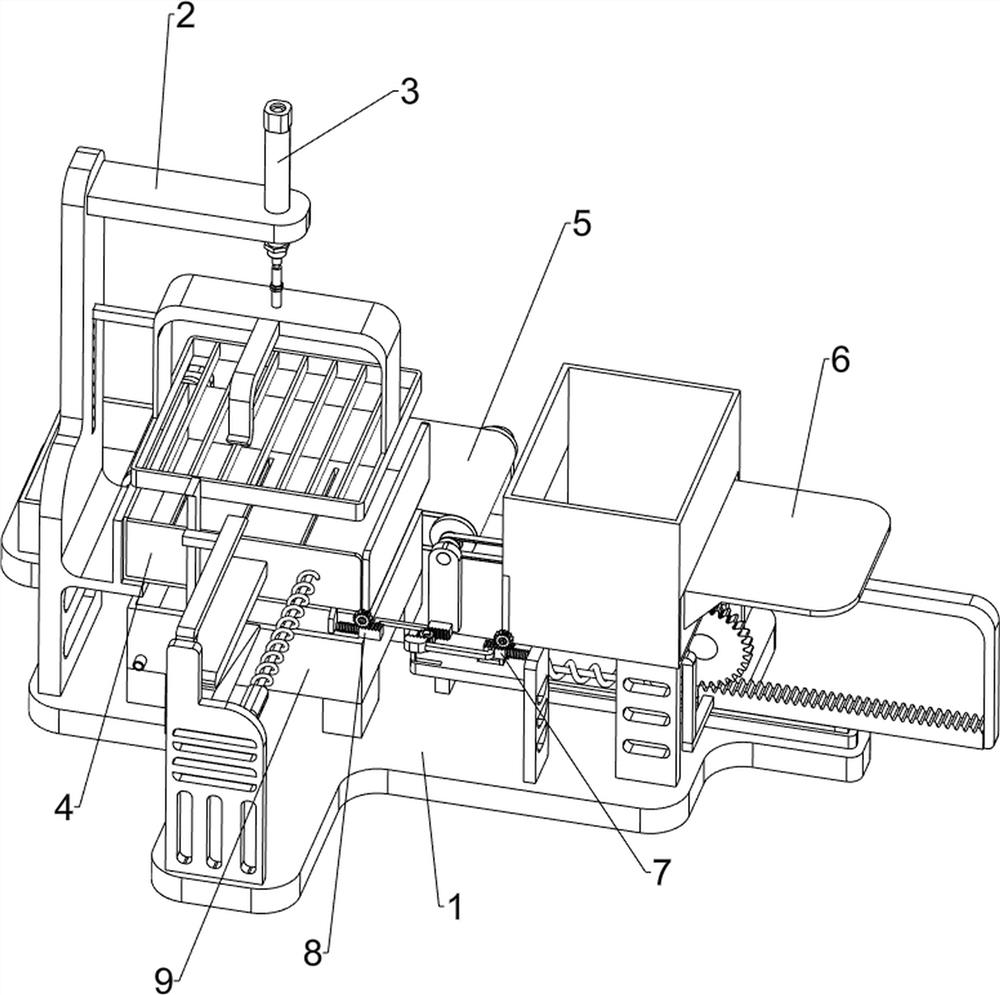

[0073] A kind of radish cutting device for food, such as figure 1As shown, it includes a bottom plate 1, a first support frame 2, a pressing mechanism 3 and a pushing mechanism 4. The left side of the top of the bottom plate 1 is provided with a first support frame 2, and the first support frame 2 is provided with a pressing mechanism 3. A pushing mechanism 4 is provided on the front side of the top of the bottom plate 1 .

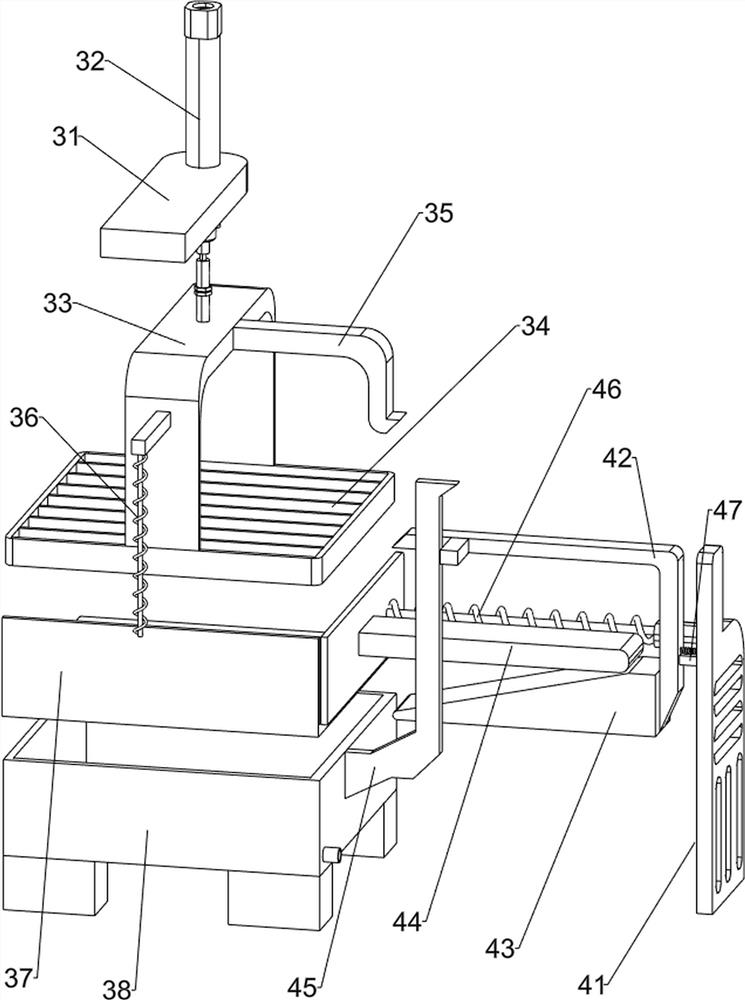

[0074] like figure 2 As shown, the pressing mechanism 3 includes a fixed block 31, a cylinder 32, a connecting block 33, a cutter group 34, a first stop bar 35, a first return spring 36, a supporting plate 37 and a water storage box 38, and the first support frame 2 The right side of the upper part is provided with a fixed block 31, the right side of the fixed block 31 is provided with a cylinder 32, the upper side of the first support frame 2 is slidingly provided with a connecting block 33, the bottom of the connecting block 33 is provided with a cutte...

Embodiment 2

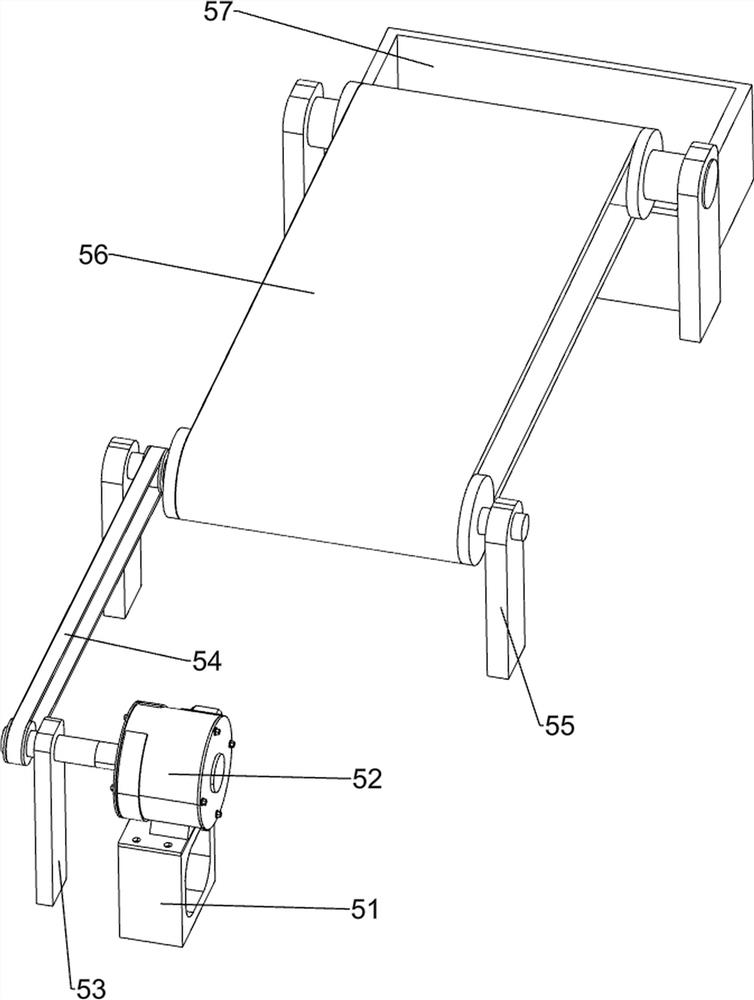

[0078] On the basis of Example 1, such as image 3 Shown, also include conveying mechanism 5, conveying mechanism 5 includes first supporting base 51, motor 52, the 3rd supporting frame 53, the first pulley set 54, the 4th supporting frame 55, the second pulley set 56 and receiving material Box 57, base plate 1 top right rear side is provided with first supporting base 51, first supporting base 51 top is provided with motor 52, base plate 1 top right rear side is provided with the 3rd supporting frame 53, motor 52 output shaft and the 3rd support Frame 53 rotates and fits, and base plate 1 top left rear side is evenly provided with four the 4th support frames 55, and the 4th support frame 55 is connected with the second pulley set 56 in rotation, the second pulley set 56 right side drive shafts and A first pulley set 54 is connected between the output shafts of the motor 52 , and a receiving box 57 is provided on the left rear side of the top of the bottom plate 1 .

[0079] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com