Coaxial double-spindle carbon fiber winding machine

A technology of carbon fiber and wire collecting machine, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of affecting the efficiency of wire collection and low degree of automation, so as to achieve a high degree of automation and maintain the stability of the wire path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

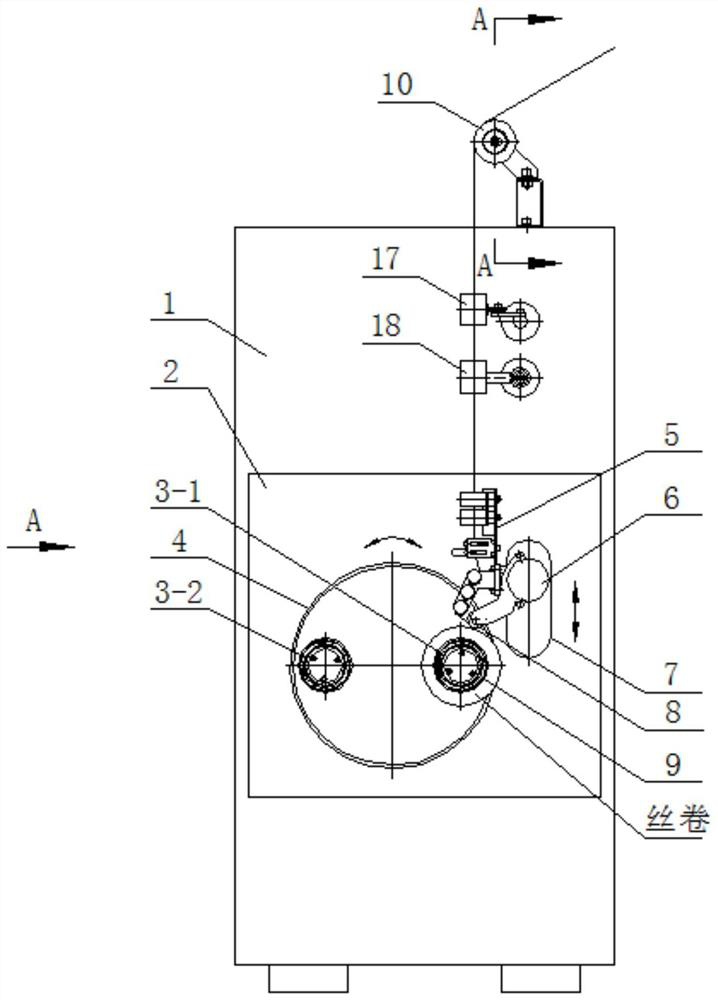

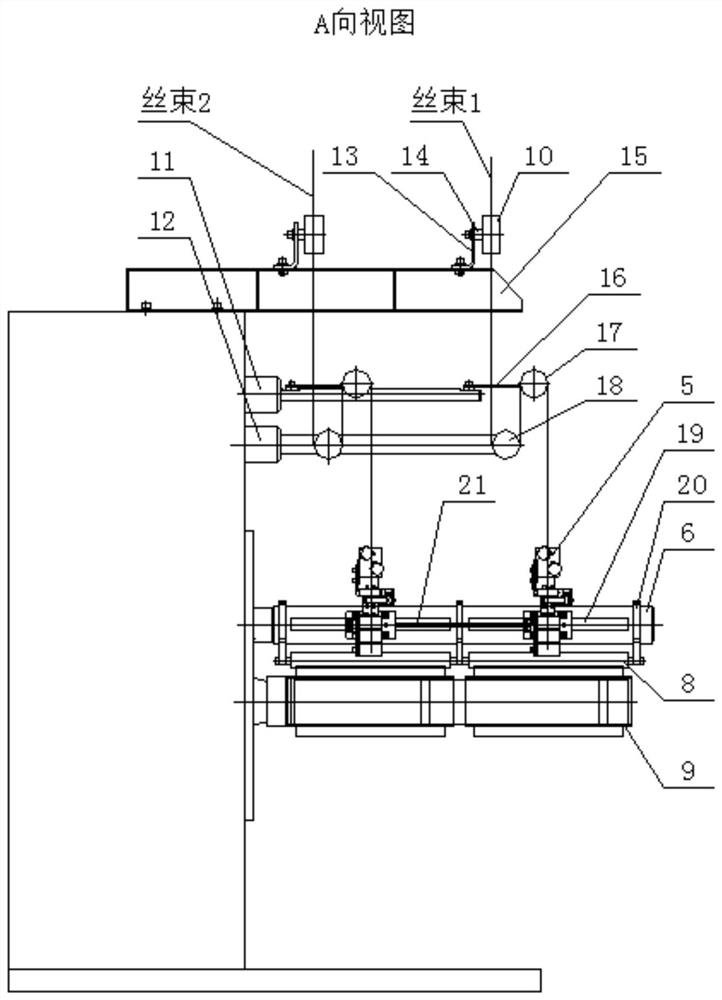

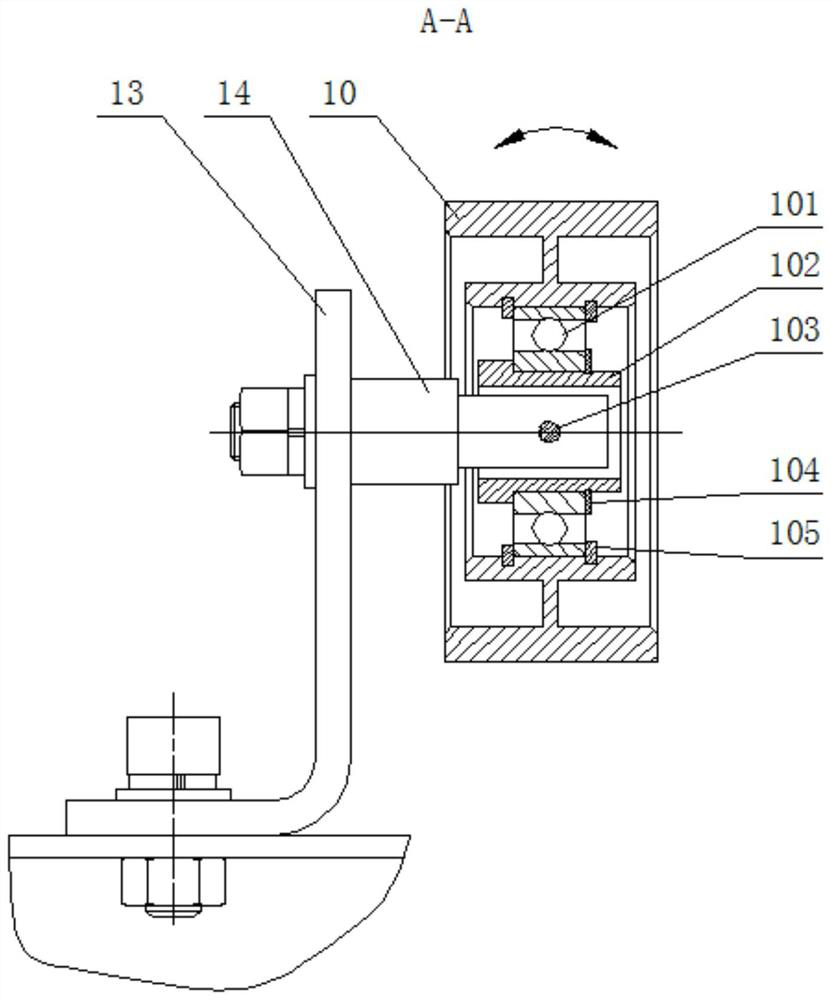

[0020] refer to Figure 1 to Figure 3 A specific implementation of a coaxial twin-spindle carbon fiber winding machine of the present invention will be further described.

[0021] A coaxial double-spindle carbon fiber winding machine, such as figure 1 and figure 2 As shown, it includes a frame 1, and the frame 1 is sequentially provided with a wire guiding device, a cable arrangement 6 and a winding device, and the winding device includes a rotary disk 4 that is rotatably installed on the frame 1. Two spindle shafts 3 are installed on the rotary disk 4, and two bobbin tubes 9 are arranged on each of the spindle shafts 3. The tubes 9 correspond to two groups, and the wire guide device is provided with a tension adjusting device.

[0022] The turntable 4 is installed on the panel 2, the panel 2 is fixedly connected with the frame 1, the turntable 4 is connected with a power device capable of driving it to rotate, and the turntable 4 is provided with two spindle shafts 3, nam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com