High-strength low-radiation coated hollow glass for energy-saving building and preparation method of high-strength low-radiation coated hollow glass

A low-radiation coating and high-strength technology, applied in the coating and other directions, can solve the problems of hollow glass damage, low application range, glass breakage, etc., and achieve the effects of reducing shaking, protecting safety and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0037] This embodiment is an embodiment of a high-strength low-radiation coated insulating glass for energy-saving buildings.

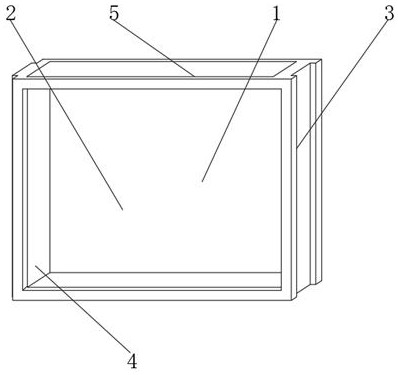

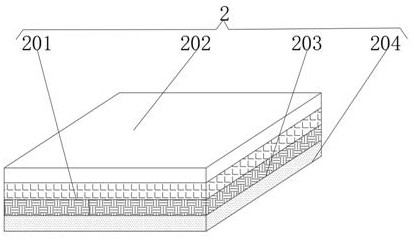

[0038] like Figure 1-2 As shown, the insulating glass body 1 is included, the outer surface of the upper and lower ends of the insulating glass body 1 is provided with a magnetic plate 5, the left and right sides of the insulating glass body 1 are provided with a splicing mechanism 3, and the front and rear ends of the insulating glass body 1 are provided with The high-strength mechanism 2 is provided with a protective mechanism 4 inside the hollow glass body 1 , and the high-strength mechanism 2 includes a high-strength layer 201 , a coating layer 202 , a radiation layer 203 and a protective layer 204 .

[0039] The insulating glass main body 1 and the high-strength mechanism 2 are integrally formed. There is a No. 1 fixing bolt between the magnetic plate 5 and the insulating glass main body 1, and the outer surfaces of the upper and lower ends of t...

specific Embodiment 2

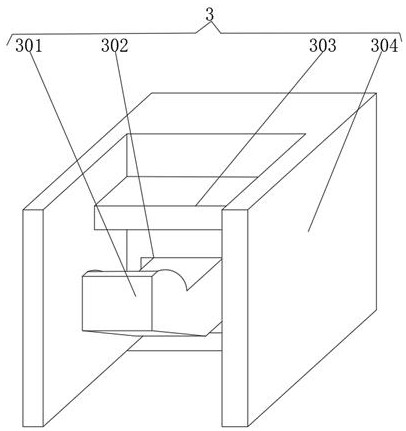

[0042] This embodiment is an embodiment of a splicing structure in high-strength low-radiation coated insulating glass for energy-saving buildings.

[0043] like figure 1 , 3 , 4, the splicing mechanism 3 includes a buckle assembly 301, a splicing groove 302, a soft buffer block 303, a splicing frame 304 and an extruding spring 305, and the outer surface of the front end of the splicing frame 304 is provided with a splicing groove 302, and the snap assembly 301 is located inside the splicing groove 302, the buffer soft block 303 is located on the outer surface of the front end of the splicing frame 304 and is located at the upper end of the splicing groove 302, and the pressing spring 305 is located inside the splicing groove 302 and is located at the rear end of the buckle assembly 301 The outer surface.

[0044] No. 1 superglue is arranged between the buffer soft block 303 and the splicing frame 304, and the rear end outer surface of the buffer soft block 303 is fixedly co...

specific Embodiment 3

[0047] This embodiment is an embodiment of a protective structure in a high-strength low-radiation coated hollow glass for energy-saving buildings.

[0048] like figure 1 , 5 As shown, the protective mechanism 4 includes a protective shell 401, a hollow glass blocking plate 402, a soft spacer strip 403, a sealing pad 404, a protective soft pad 405, a stable groove 406, a stable extrusion disc 407 and an extrusion circular groove 408, sealing The pad 404 is located on the outer surface of the front end of the protective shell 401, the spacer soft strip 403 is located on the outer surface of the front end of the gasket 404, the insulating glass blocking plate 402 is located on the outer surface of the front end of the protective shell 401 and runs through the wall of the sealing gasket 404, and the insulating glass blocking plate 402 is located at the upper and lower ends of the spacer soft strip 403, and the inner surface of the upper and lower ends of the protective shell 401...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com