Blender for equivalently mixing base liquor for brewing white spirit

A technology of equal amount mixing and base wine, applied in the field of liquor blending, can solve the problems of labor-intensive, low efficiency, inaccurate blending ratio, etc., and achieve the effect of preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

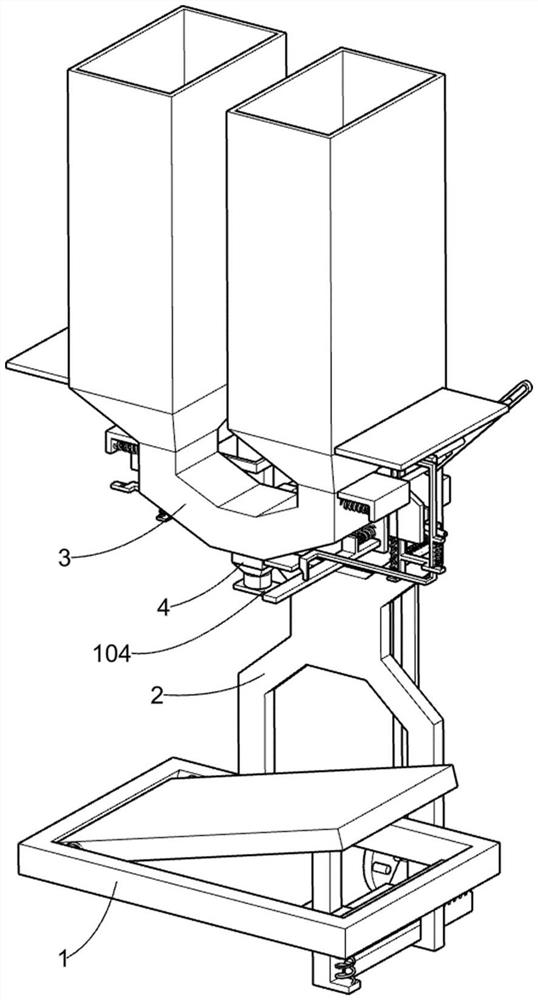

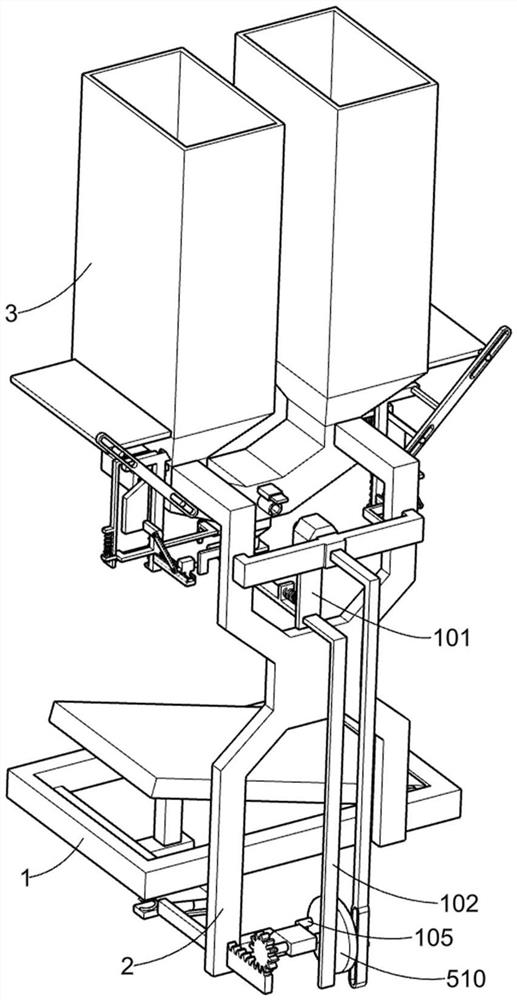

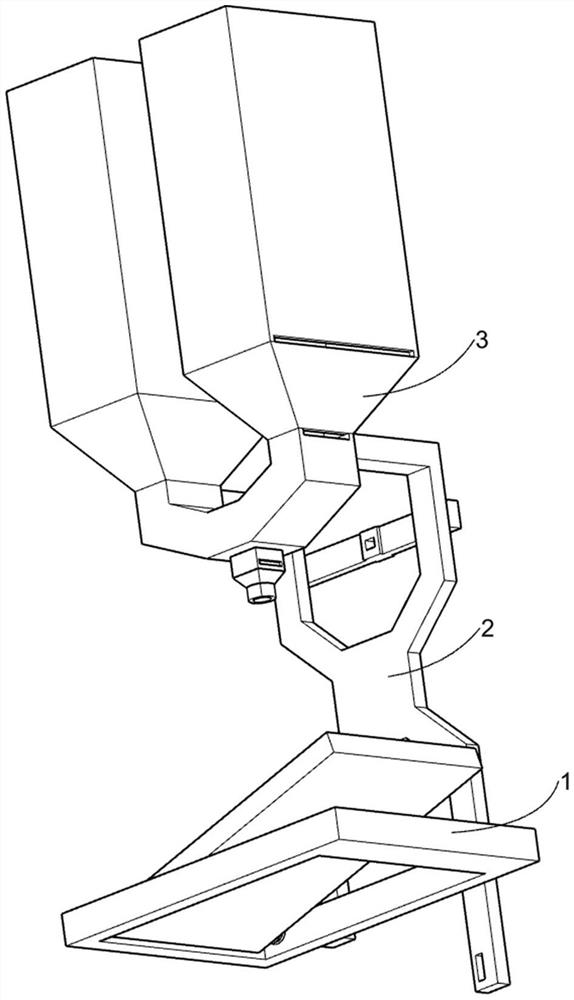

[0029] A kind of blender for mixing and blending the same amount of base wine for liquor brewing, such as Figure 1-10 As shown, it includes a return frame 1, a bracket 2, a blending frame 3, a drain pipe 4, a pressing component 5, a stirring component 6, a stretching component 7, a quantitative wine sealing component 8, a flow-stop component 9, and a bracket 2 Connected to the return frame 1, the blending frame 3 is positioned on the support 2, the drain pipe 4 is connected to the bottom of the blending frame 3, the drain pipe 4 is used to discharge the blended liquor, on the return frame 1, the agitation assembly 6 is set on the support 2, the agitating component 6 is used to fully stir the base wine mixed on the blending frame 3, the stretching component 7 is arranged on the blending frame 3, the quantitative wine sealing component 8 is set on the stretching component 7, and the quantitative wine is sealed The component 8 is used to make the base wine on the blending frame ...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 10 As shown, it also includes a wiping assembly 10. The wiping assembly 10 is arranged on the agitating assembly 6. The wiping assembly 10 is used to prevent the liquor in the drain pipe 4 from being exposed to air and causing deterioration. The wiping assembly 10 includes a guide plate 101, an L-shaped bar 102, the third compression spring 103, the sponge plate 104 and the push rod 105, the guide plate 101 is located at the bottom of the guide plate 61, the L-shaped bar 102 is slidably connected to the guide plate 101, a third link is connected between the guide plate 101 and the L-shaped bar 102 Compression spring 103, the third compression spring 103 is used to drive the L-shaped bar 102 and its upper device to reset. In contact with the drain pipe 4 , the push rod 105 is connected to one side of the drive plate 510 , and the push rod 105 is used to push the L-shaped bar 102 and its upper device to move away from the return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com