Roadbed widening structure under steep terrain condition and construction method thereof

A technology based on topography and conditions, applied in the direction of basic structure engineering, underwater structures, roads, etc., can solve the problems that excavation and retaining structures are difficult to meet engineering needs, the number of foam concrete projects is large, and foam concrete is easy to crack. Achieve the effects of reducing construction difficulty and construction risk, improving anti-slip ability, and reducing the volume of dock workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

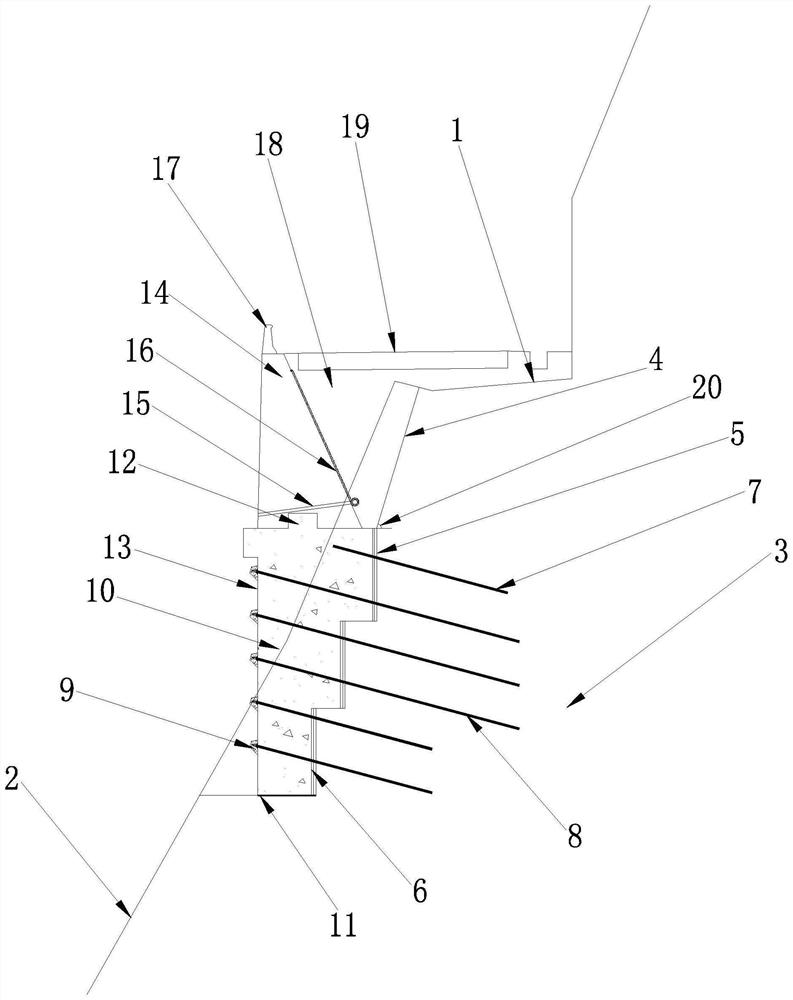

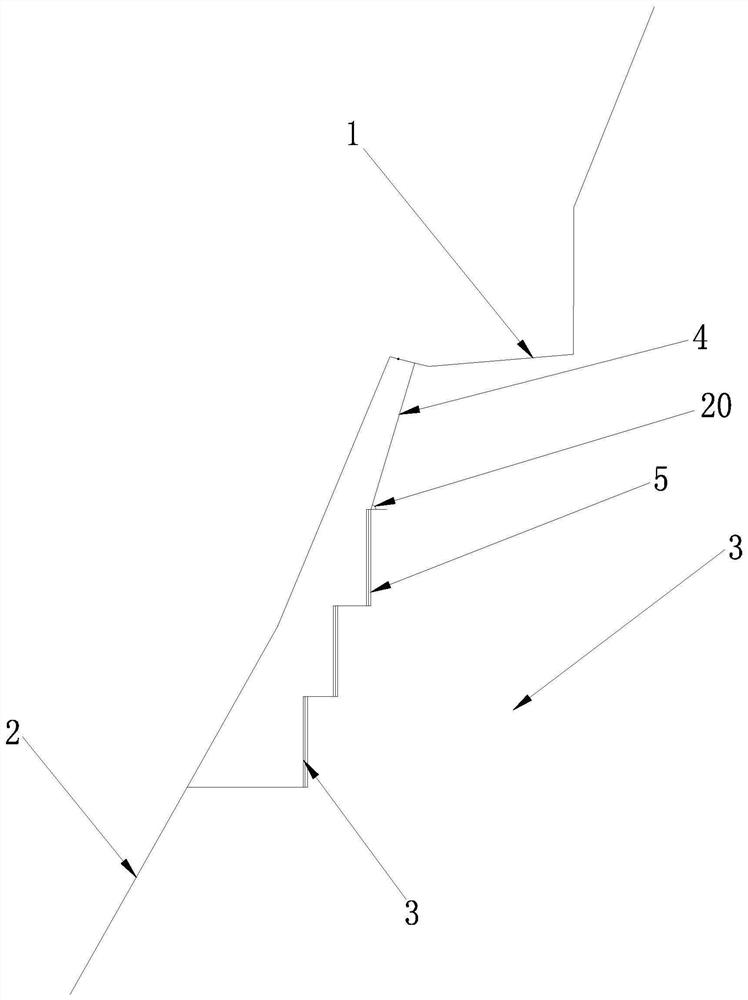

[0035] Such as Figure 1-3 As shown, the roadbed widening structure provided by this embodiment includes a mountain body 3, and the mountain body 3 includes an old road 1 and a steep wall 2 located on the valley side of the old road 1, and the steep wall 2 on the valley side is excavated inward to form a wall Excavate the side wall 4 and the stepped artificial steep wall 5 after excavation; the stepped artificial steep wall 5 is provided with anchoring steel bars 7 and multiple anchor rods 8 of different heights, and the anchoring steel bars 7 and anchor rods 8 are anchored inward along the stepped artificial steep wall 5 The mountain body 3; the outer side of the stepped artificial steep wall 5 is provided with a concrete step foundation 10; the top of the step foundation is provided with a step foundation tenon 12 and is connected with the retaining wall 14 as a whole; the backfill filler 18 is compacted behind the retaining wall 14 After that, it is spliced with the old r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap