Quantitative pressure suction valve

A valve body and air pressure technology, used in control valves, valve devices, valve details, etc., can solve problems such as physical impact, home decoration loss, air and water pollution, etc., to reduce odor, eliminate pollution, and save material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

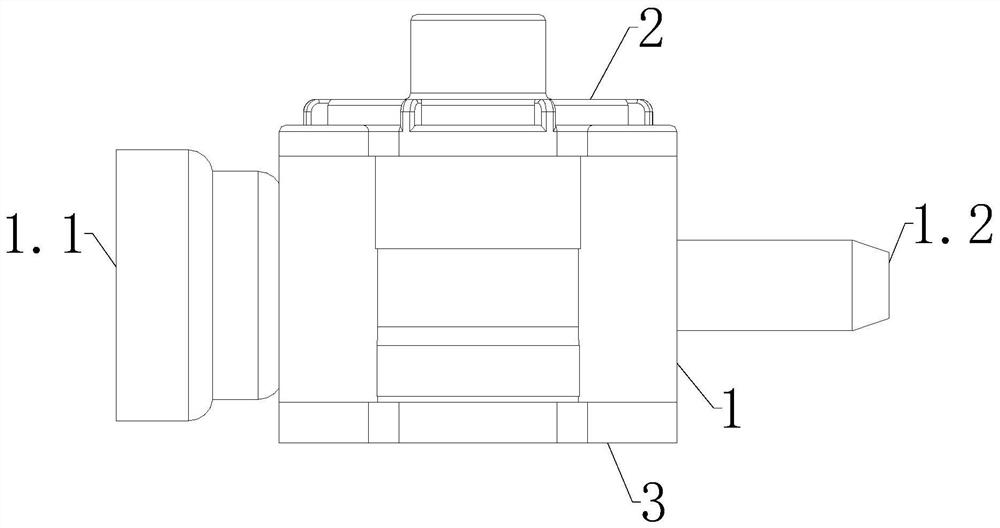

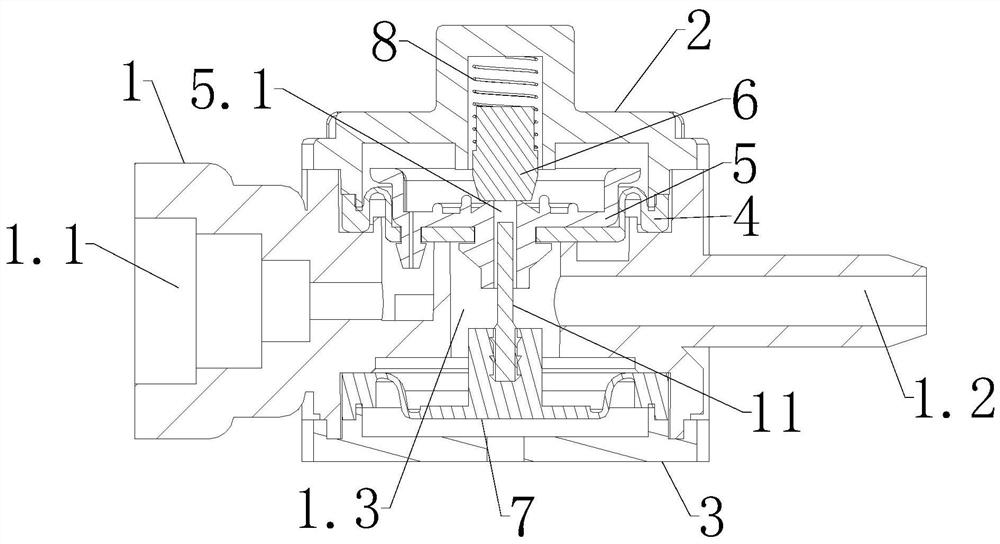

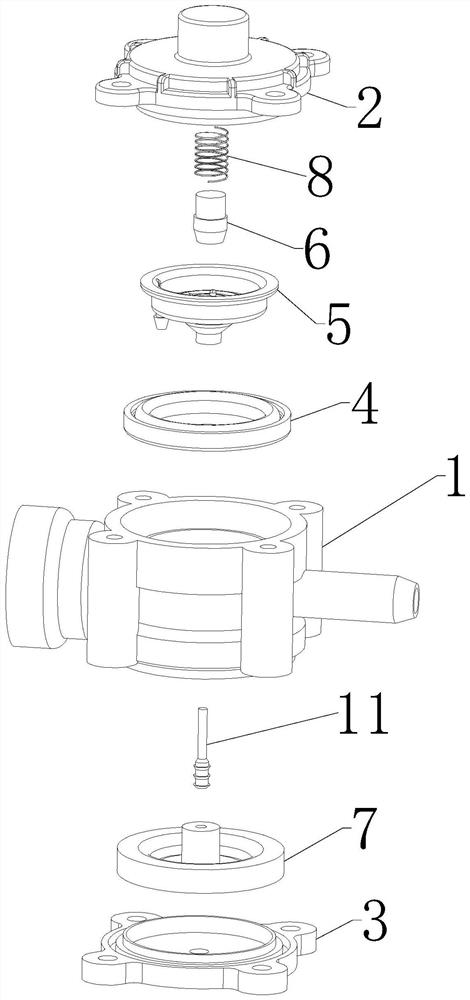

[0034] Embodiment one: if figure 1 — Figure 4 As shown, the quantitative suction valve includes a valve body 1, the top and bottom of the valve body 1 are respectively equipped with an upper cover 2 and a lower cover 3, and the left and right sides of the valve body 1 have a water inlet 1.1 and a suction water outlet 1.2 respectively. The upper end of 1 is fixed with a hydraulic pressure diaphragm 5 through a support frame 4, the outer edge of the support frame 4 is stuck between the upper end of the valve body 1 and the lower end of the upper cover 2, the hydraulic diaphragm 5 is connected to the water inlet 1.1, and the water pressure The center of the diaphragm 5 has a central diversion hole 5.1 that communicates with the suction outlet 1.2;

[0035] The top of the hydraulic diaphragm 5 is pressed with a sealing column 6 for blocking the central diversion hole 5.1, the upper cover 2 is equipped with a pressing piece for pressing the sealing column 6 downward, and the lowe...

Embodiment 2

[0042] Embodiment two: if Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the lower pressing member is composed of a first magnet 9 and a second magnet 10, the first magnet 9 is fixed in the upper cover 2, and the second magnet 10 is fixed on the upper end of the sealing column 6 , the first magnet 9 is located above the second magnet 10 and repels the second magnet 10 , and the outer wall of the sealing column 6 is in contact with the inner wall of the upper cover 2 . The sealing column 6 can tightly block the upper end of the central diversion hole 5.1 through the repulsive force between the first magnet 9 and the second magnet 10 .

Embodiment 3

[0043] Embodiment three: as Image 6 As shown, the difference between the third embodiment and the first embodiment is that the top piece is installed between the air pressure diaphragm 7 and the sealing column 6, the top piece is composed of the third magnet 12 and the fourth magnet 13, and the third magnet 12 is fixed At the bottom of the sealing column 6 and extending into the center diversion hole 5.1, there is a gap for water to pass between the third magnet 12 and the inner wall of the center diversion hole 5.1, the fourth magnet 13 is fixed on the upper end of the air pressure diaphragm 7, and the fourth The magnet 13 is located below the third magnet 12 and repels the third magnet 12. When the fourth magnet 13 moves upward, the third magnet 12 is driven by the repulsive force of the fourth magnet 13 to move the sealing column 6 upward, so that the central guide hole 5.1 The upper end is opened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com