Weld bead contour determination method and device, processor and system

A technology for predetermined processing and welding bead, applied in the field of device, welding bead profile determination method, processor and system, computer readable storage medium, and can solve the problem that the welding bead profile cannot be accurately extracted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

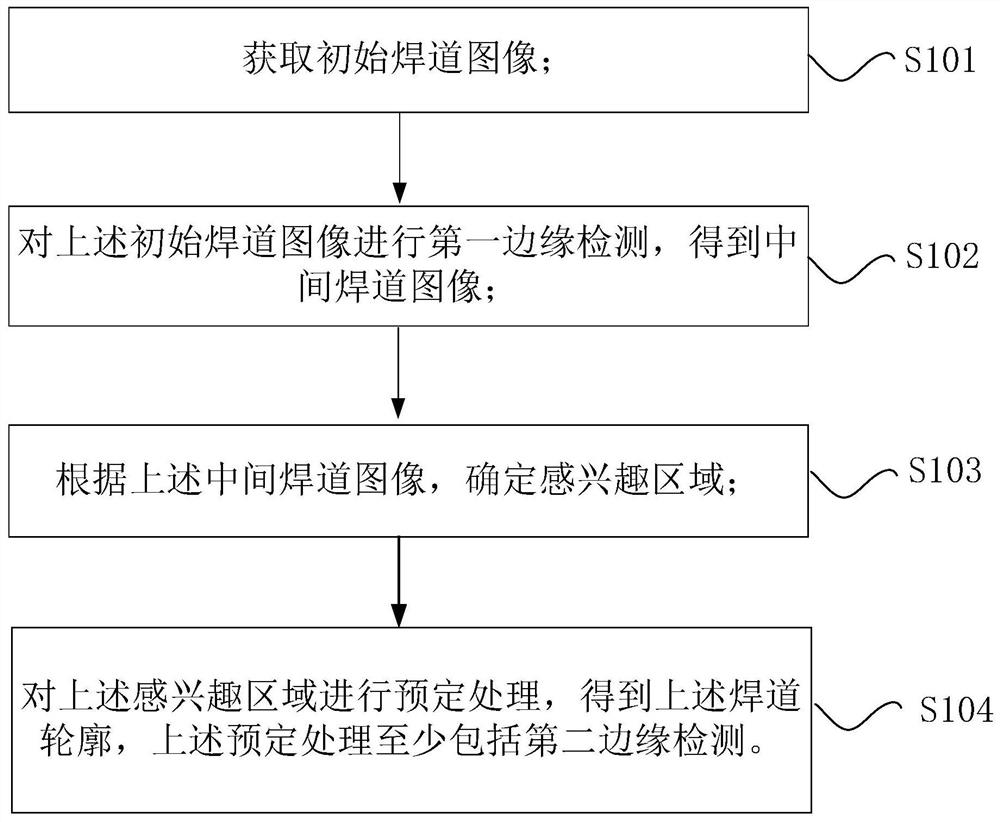

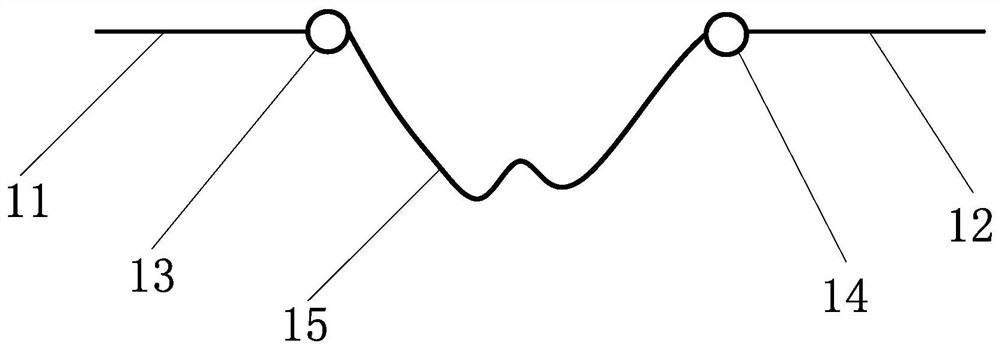

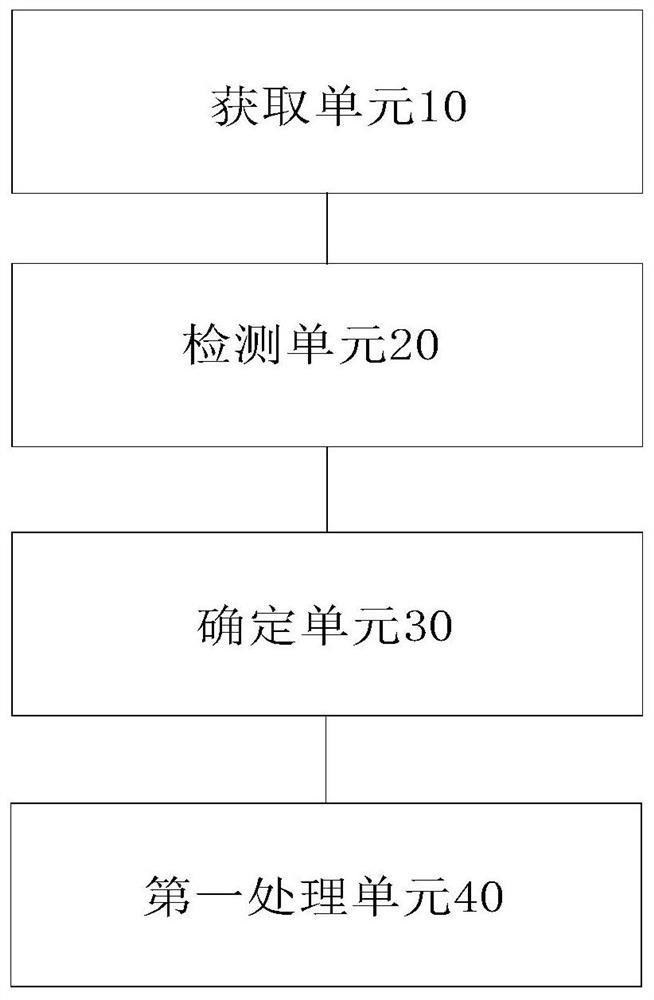

[0085] Such as Figure 4 As shown, the initial weld bead image is collected first, and the Laplacian image enhancement algorithm is used for image enhancement on the initial weld bead image, and then the rough edge detection algorithm is used for the first edge detection, and the false edges, left and right edges in the initial weld bead image are extracted. The initial edge and the initial edge of the weld bead, and then remove the detected false edge according to the characteristics of the edge, and further obtain the left and right initial edges and the initial edge of the weld bead, and then determine the position of the initial left and right inflection points according to the positional relationship between the initial edges, according to The position of the determined initial left and right inflection points determines the region of interest of the weld bead contour line, and then uses the adaptive threshold edge detection algorithm to perform a second edge detection on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com