Grass combing machine for gardens and use method

A grass combing machine and grass combing technology, applied in the application, harvester, agricultural machinery and implements and other directions, can solve the problems of single grass brushing distance and the inability to guarantee the effect of lawn brushing, so as to beautify the environment, avoid damage, reduce Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

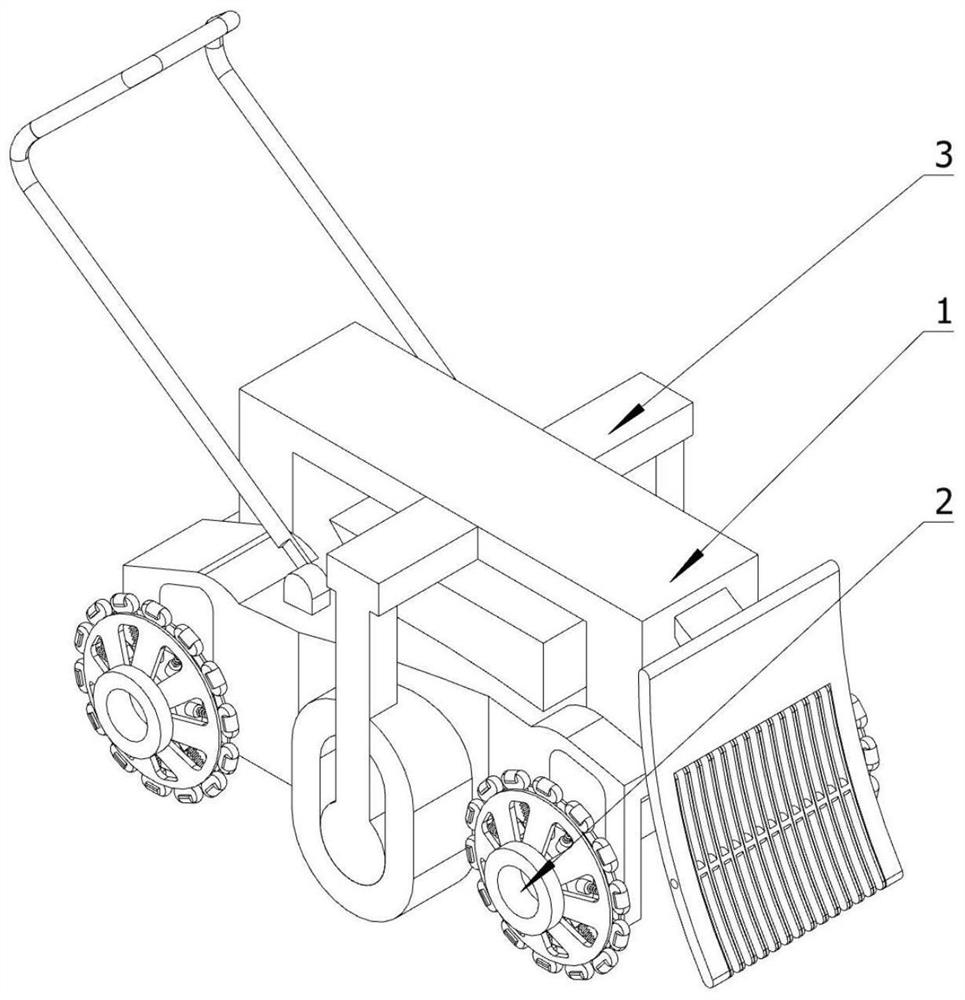

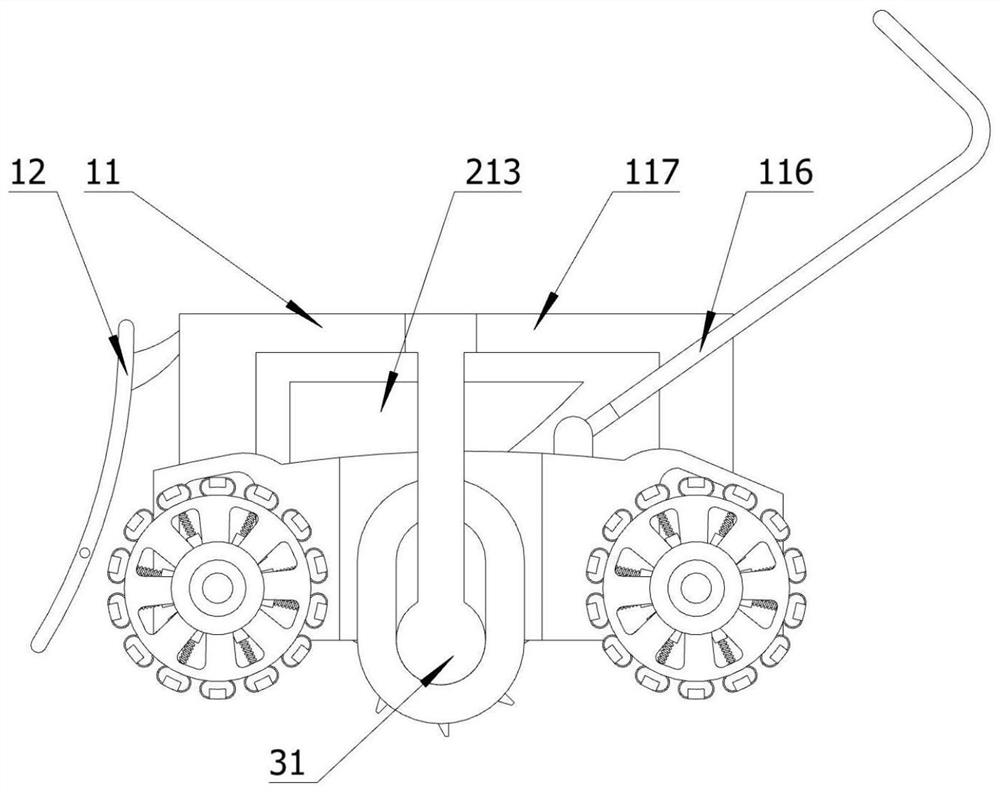

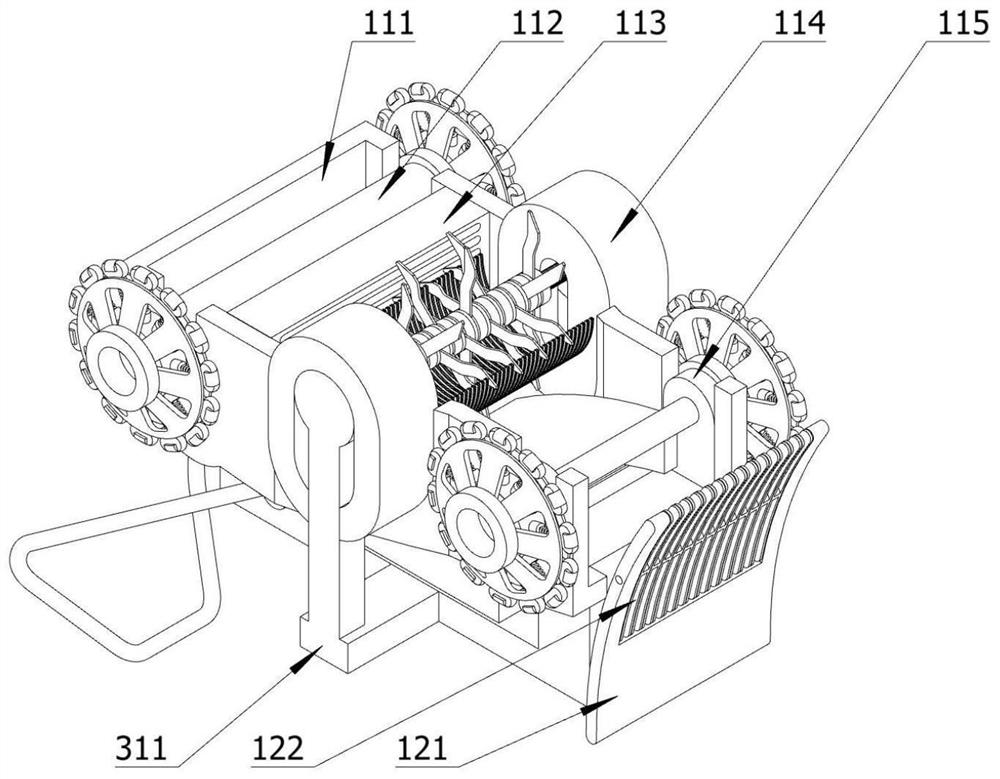

[0047] A garden grass combing machine, characterized in that it includes: a housing part 1, the housing part 1 is arranged on the ground, and the housing part 1 includes: a grass combing housing 11, and the grass combing housing 11 is arranged on the ground, The grass combing housing 11 comprises: the grass combing shell 111, the grass combing shell 111 is arranged on the ground, the front, middle and rear parts of the grass combing shell 111 are provided with through installation grooves, and the top of the grass combing shell 111 is provided with The handle installation platform, the top of the grass-combing housing 111 is also provided with a skylight, the grass-combing rear axle 112, the grass-combing rear axle 112 is connected in the through installation groove at the rear of the grass-combing housing 111, and the upper end of the grass-combing rear axle 112 is provided with Fixed bar, grass-combing fan 113, grass-combing fan 113 is connected inside the grass-combing shell...

Embodiment 2

[0051] Same as Embodiment 1, a garden grass combing machine is characterized in that it includes: a housing part 1, the housing part 1 is arranged on the ground, and the housing part 1 includes: a grass combing housing 11, a grass combing housing 11 is arranged on the ground, and the grass combing housing 11 includes: the grass combing shell 111, the grass combing shell 111 is arranged on the ground, and the front, middle, and rear parts of the grass grooming shell 111 are provided with through installation grooves, and the grass combing shell 111 is provided with through installation grooves. The top of the housing 111 is provided with a handle mounting platform, and the top of the housing 111 is also provided with a sunroof. The upper end of the shaft 112 is provided with a fixed rod, the grass-combing fan 113, the grass-combing fan 113 is connected to the inside of the grass-combing housing 111, the grass-combing central axis 114, and the grass-combing central axis 114 is co...

Embodiment 3

[0055] A method for using a lawn comber for gardens, comprising the following steps:

[0056] Start the traveling part 2, the traveling device 21 of the traveling part 2 starts to work, and the traveling device 21 rotates to drive the housing part 1 to move. , the motor in the recovery plate 121 of the recovery device 12 starts to work, and the motor drives a plurality of recovery rotors 122 to rotate. When rotating, on the one hand, the higher grass is combed through the distance between the recovery rotors 122, and on the other hand On the one hand, the garbage inside the lawn is taken out by the rotation of the recycling rotating piece 122, and when the recycling rotating piece 122 rotates to the second half, the garbage is brought into the recycling box 123.

[0057]After passing through, after the recycling device 12 has processed the garbage, the grass combing device 32 begins to touch the grass surface that needs to be combed. For the height of the grass plane, by adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com