Green vegetable harvester

A green leafy vegetable harvester technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of heavy labor and low efficiency of manual picking, avoid mutual extrusion, provide harvesting efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

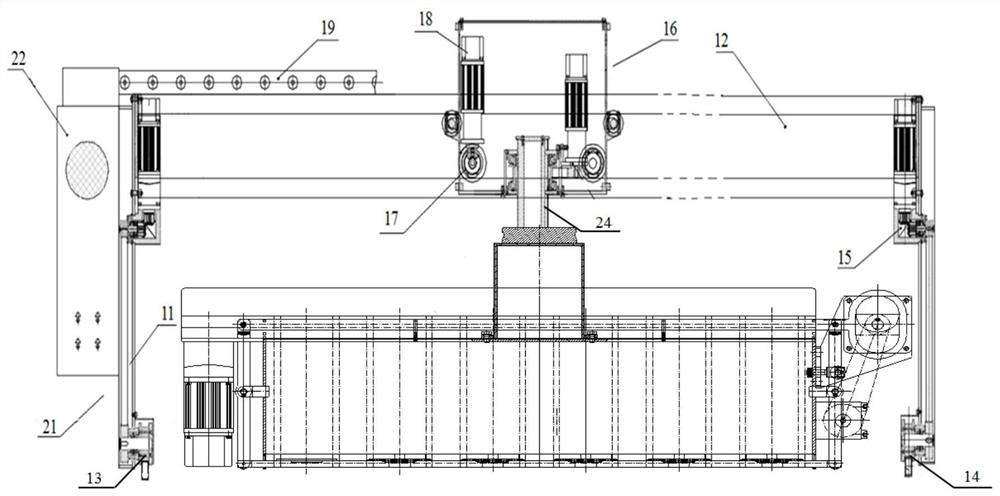

[0030] Embodiment 1 is wherein a kind of structure of the present invention, as figure 1 As shown, it includes: a greenhouse machine frame and a green leafy vegetable harvesting device arranged on the greenhouse machine frame;

[0031] Among them, the greenhouse machine frame includes: first guide rails and second guide rails arranged in parallel and a door-shaped traverse frame straddling the first guide rail and the second guide rail. The bottom of the support frame of the door-shaped traverse frame is provided with a useful For the first moving mechanism that moves along the first and second guide rails, the door-shaped beam frame is provided with a second moving mechanism that moves along the beam frame, and the working head connecting device is arranged vertically on the second moving mechanism. The second moving mechanism includes a telescopic rod 24 arranged in the vertical direction;

[0032] In this embodiment 1, the first moving mechanism includes a first moving whe...

Embodiment 2

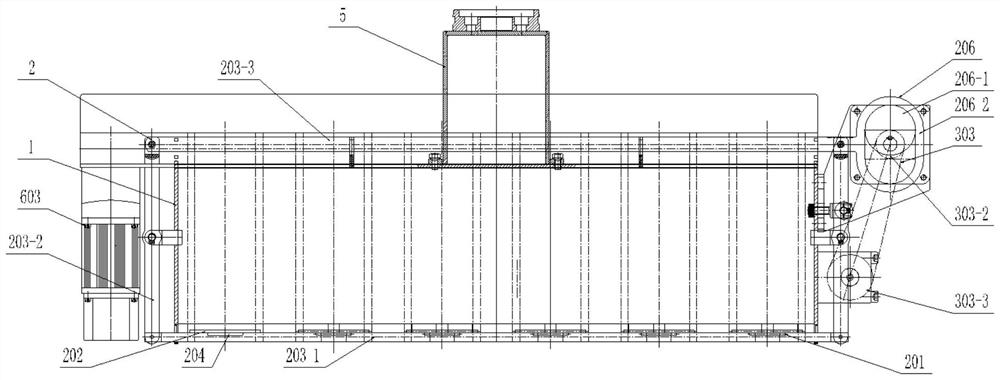

[0036] In this embodiment 2, if figure 2 As shown, the harvesting device 2 includes: on the lower support beam of the frame 1, a shovel plate 201 is fixedly arranged at a predetermined angle downwardly inclined along the horizontal direction between the two support plates, and several V Type shoveling groove 202, corresponding to V-shaped shoveling groove 202 below the scraping plate 201 is provided with cutting knife 204 respectively, also includes: driving device 4, driving device 4 drives cutting knife 204 to do horizontal reciprocating cutting action. Wherein, the driving device 4 is configured as a driving motor.

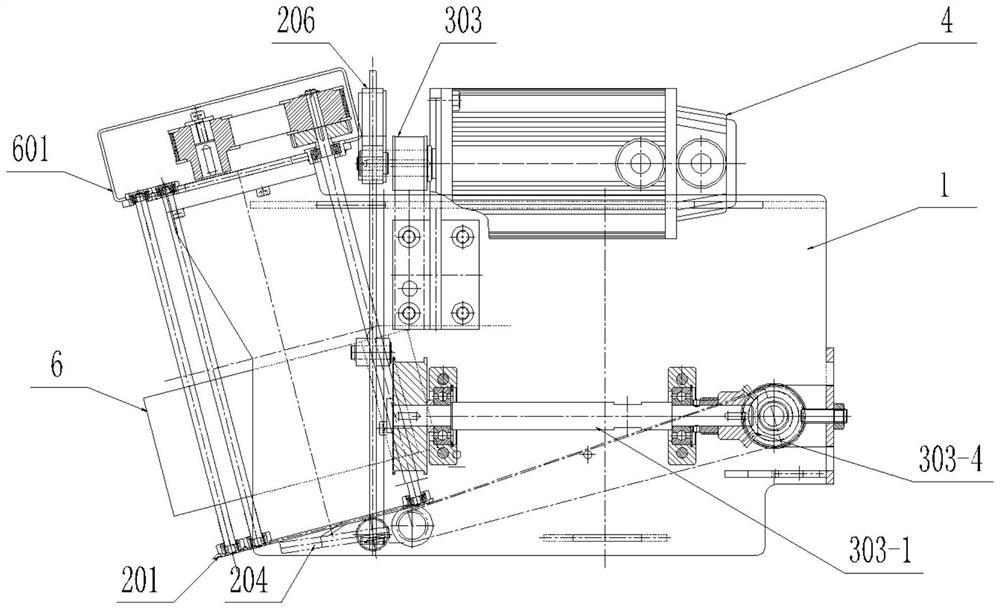

[0037] Such as image 3 , as shown in 4, the transmission device 3 includes: a belt roller transmission mechanism is fixedly arranged on the frame 1 corresponding to the shovel plate 201, and the driving motor is connected to the belt roller transmission mechanism.

[0038] In this second embodiment, a four-bar linkage mechanism is hinged on the frame 1 corres...

Embodiment 3

[0042] Embodiment 3 is a kind of deformation structure of embodiment 2, and its difference with embodiment 2 is: as image 3 , as shown in 4, the conveying device 3 is arranged on the frame 1 behind the sloping upward side of the shovel plate 201, including: a driving conveying roller assembly 301 and a driven conveying roller assembly 302 are arranged to rotate on the frame 1, and A conveyor belt is set corresponding to the shoveling plate 201 between the driving transmission roller assembly 301 and the driven transmission roller assembly 302, wherein the above-mentioned driving motor is connected to the driving transmission roller assembly 301 through an engaging transmission device 303;

[0043] Such as Figure 7 , as shown in 8, the driving transmission roller assembly 301 includes: the driving transmission shaft is arranged on the frame 1 through the rotation of the bearing device, and the driving wheel is fixedly arranged on the driving transmission shaft; the driven tra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap